Prescription of biodegradable soybean protein thermoplastic material

A thermoplastic material, soybean protein technology, applied in the field of formulation of soybean product deep processing, can solve the problem of not having

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

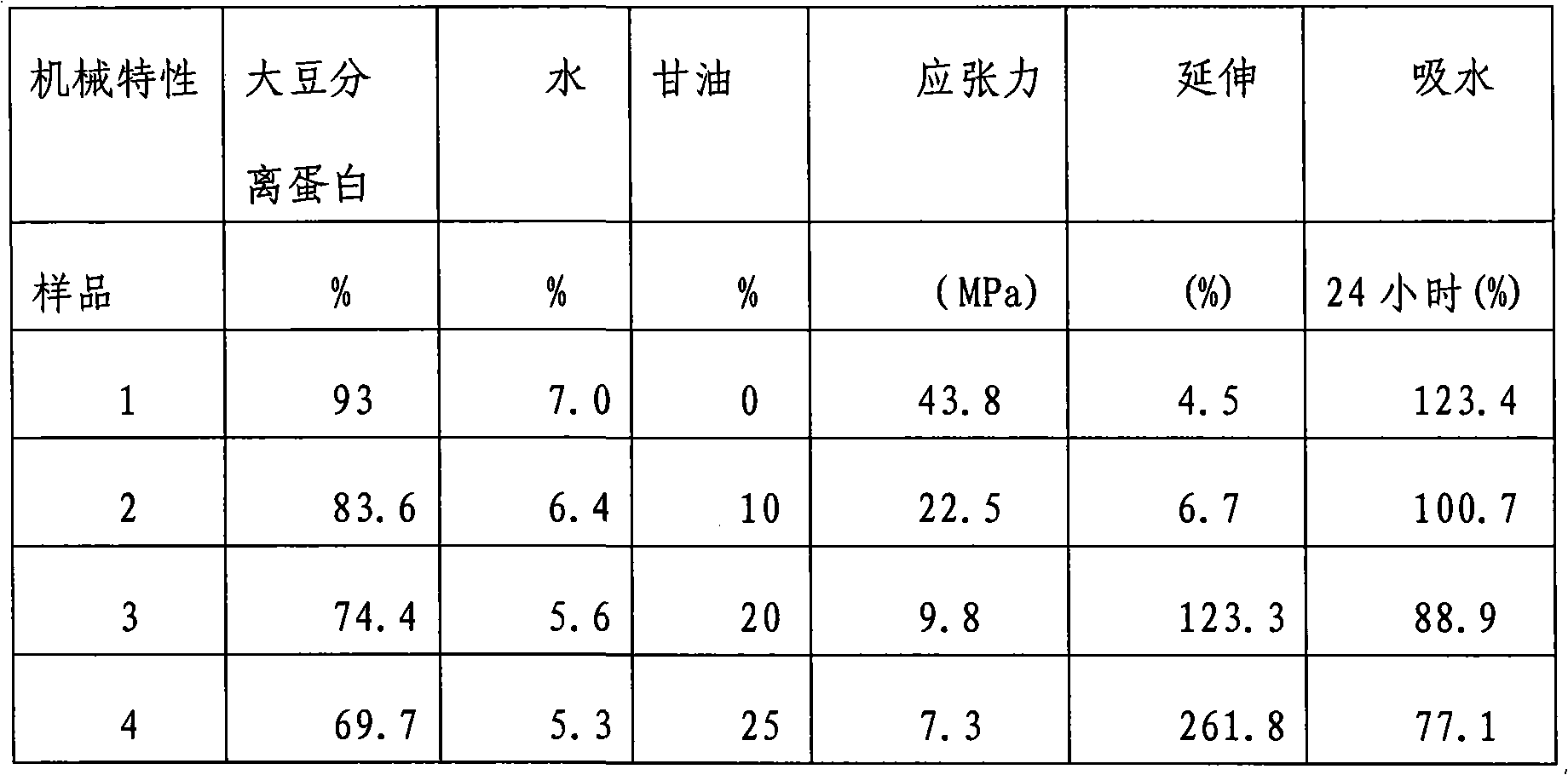

Image

Examples

Embodiment 1

[0055] Specifically: 100 parts of soybean protein, mainly composed of soybean protein concentrate or soybean protein isolate; 2 parts of reducing agent, mainly composed of sodium sulfite, ascorbic acid and sodium bisulfite; 60 parts of starch; 50 parts of plasticizer, mainly composed of glycerin Main; 20 parts of water; 2.5 parts of lubricant, mainly soybean oil; 14 parts of filler, mainly carrageenan and locust bean gum; 75 parts of cellulose, mainly short-fiber cellulose formulated into thermoplastic materials for processing .

[0056] The mixing system employed is a continuous flow mixer, such as a Teledyne continuous processor or a Breadsley Piper continuous mixer, suitably a twin screw extruder unit, the components are mixed together under high shear to form a substantially uniform texture, and The components are evenly dispersed.

[0057] The components can be mixed into a plastically uniform texture by passing the components into the first section of the twin-screw ext...

Embodiment 2

[0070] Embodiment 2 provided by the present invention: (both percent by weight) soybean protein isolate 30%; Sodium sulfite 2%; Corn starch filler, the mixture 30% of maleic acid starch, octenyl succinic acid starch, succinic acid starch, potato starch, Glycerin 15%, water 10%; soybean oil 0.5%; carrageenan 2%; short fiber 10%; preservative 0.25%; colorant 0.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com