Rare earth garnet type ferrite compound and preparation method thereof

A garnet type, ferrite technology, applied in iron compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as high temperature process, and achieve the effects of good repeatability, mild synthesis conditions and fast reaction speed

Inactive Publication Date: 2010-08-25

JILIN UNIV

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of these methods is that they all go through a high temperature process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

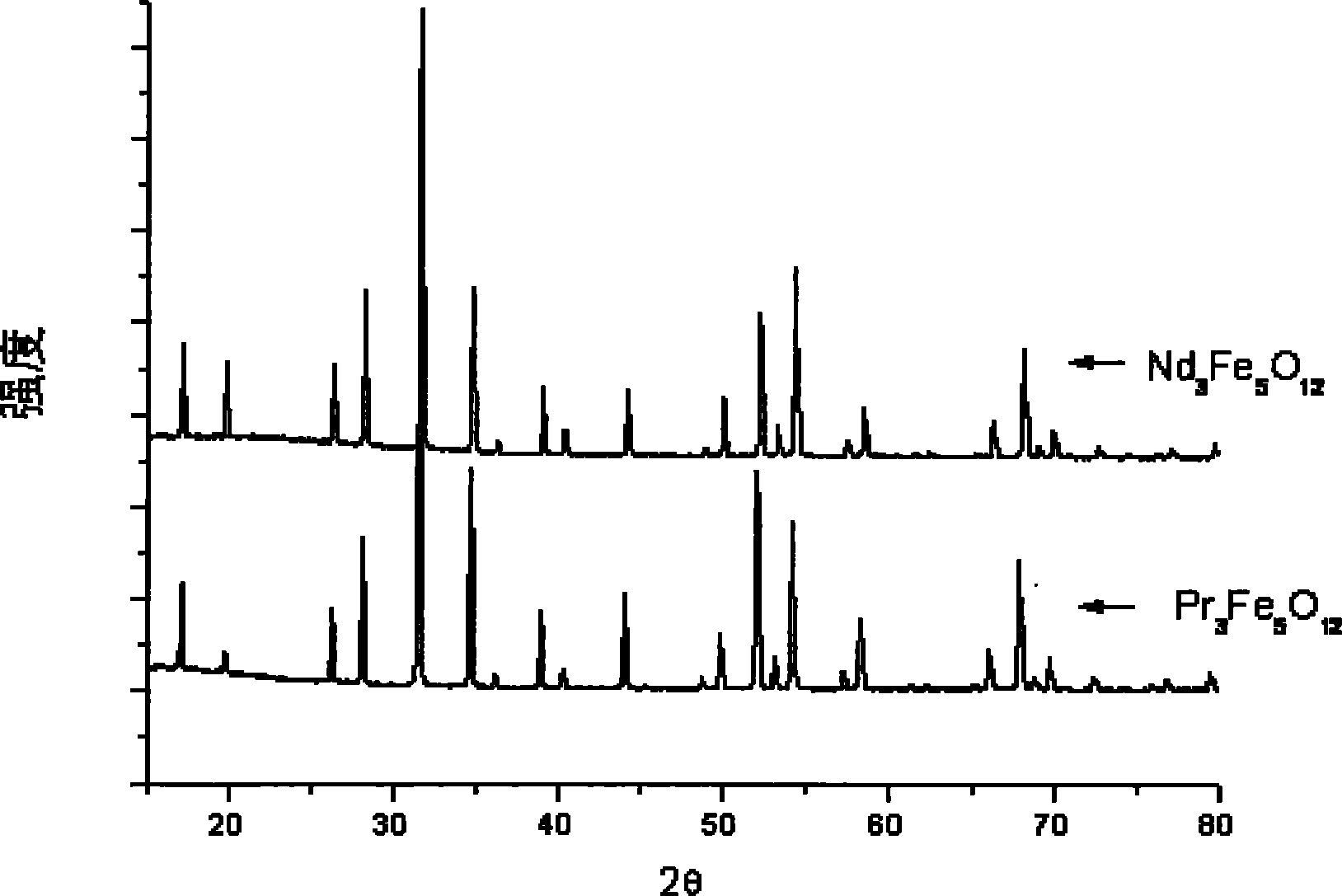

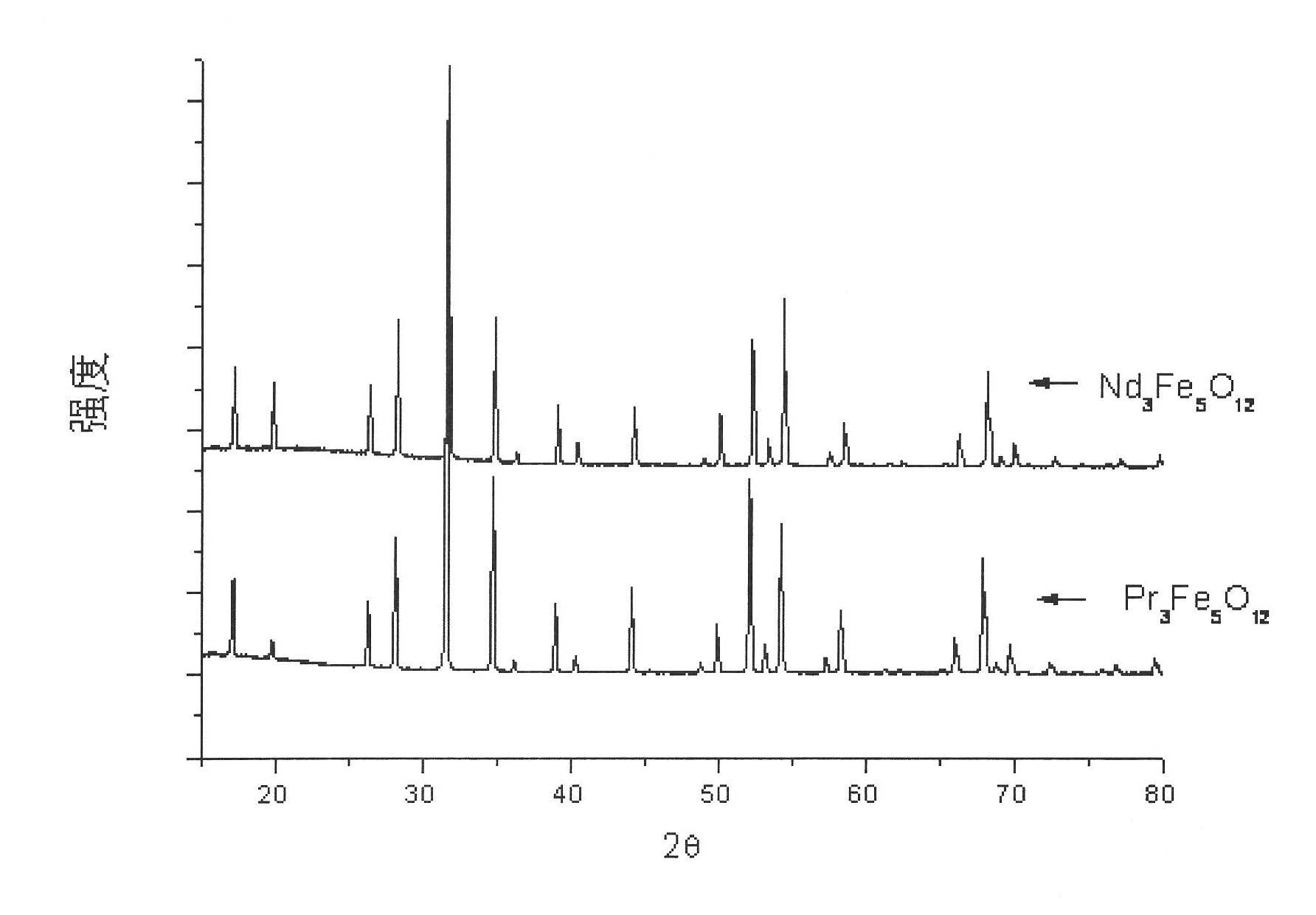

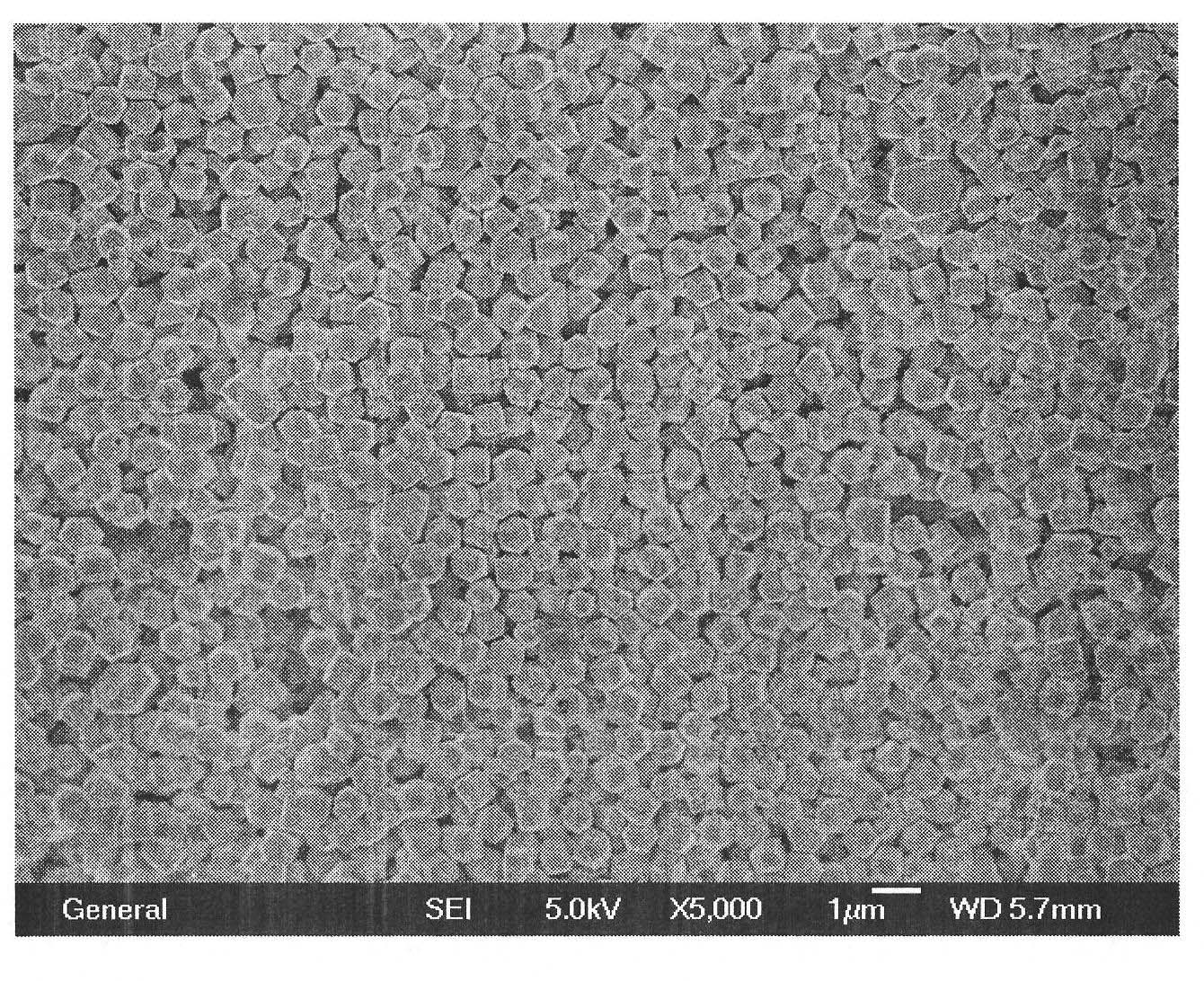

The invention discloses a rare earth garnet type ferrite compound and a preparation method thereof, which belong to the technical field of inorganic materials and preparation processes thereof. The rare earth garnet type ferrite compound comprises R3Fe[5-y]MyO12, wherein R is Pr, Nd, Sm or Eu, M is Mn, Cr or V and y is more than or equal to 0 and less than3; and calcium or strontium can be doped at C bit. In the preparation method, trivalent rare earth nitrate and Fe(NO3)3 used as reactants, MnCl2 and the like as doped metal salts and KOH as a mineralizing agent are mixed, stirred and are subjected to alkalinity adjustment and hydrothermal reaction in the presence of a large amount of mineralizing agents. The invention discloses a preparation method of the rare earth garnet type ferrite compound which is difficult to synthesize and is unstable at high temperature and has the characteristics of simple operation, mild conditions, high reaction speed, good repeatability, low cost and the like; and in addition, by using the preparation method, a pure phase product with smooth and perfect crystal can be synthesized, the grain diameter of the product is small to several hundreds of nanometers and the monocrystal X-ray analysis can be carried out when the grain diameter is approximately dozens of micrometers.

Description

Rare earth garnet type ferrite compound and preparation method thereof technical field The invention belongs to the technical field of inorganic materials and preparation techniques thereof, and relates to high-temperature thermodynamically unstable rare earth (Pr3+, Nd3+) garnet-type ferrite compounds with large ion radii and hydrothermal treatment of other rare-earth garnet-type ferrite compounds preparation. Background technique The molecular formula of garnet-type ferrite compound is similar to natural garnet R3Al2(SiO4)3, R is Fe or Mn, the crystal structure belongs to the body-centered cubic system, and the space group is la-3d. Each unit cell contains 8 molecular formulas, and Fe ions occupy 24 tetrahedral central gaps (24d) and 16 octahedral central gaps (16a), respectively. Y3+ or other trivalent rare earth element ions or other elements with slightly larger ionic radii are located at the center (24c) of 24 dodecahedrons, which are composed of eight neighbor oxyg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G49/00

Inventor 冯守华郭丽袁宏明陈岩黄科科

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com