Preparation and dispersion method and equipment of graphene/carbon nanotube composite conductive paste

A carbon nanotube composite and conductive paste technology, which is applied in the direction of carbon-silicon compound conductors, cable/conductor manufacturing, circuits, etc., can solve the problems of poor dispersion of composite paste, complicated preparation process, and affecting performance, and achieve high stability performance, simplification of the preparation process, and improvement of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

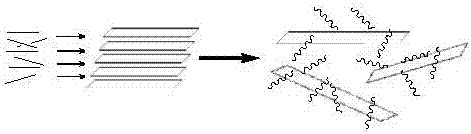

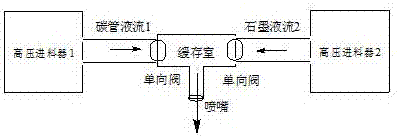

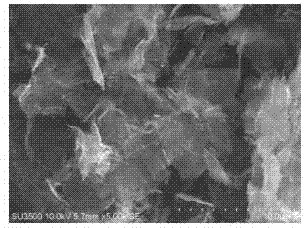

[0027] Such as Figure 1-Figure 4 As shown, the preparation method and dispersion method of a kind of graphene / carbon nanotube composite conductive paste in the present embodiment comprise the following steps:

[0028] 1. Disperse a certain amount of dispersant into the solvent, then add carbon nanotubes and stir evenly with a high-speed mixer, and then perform preliminary grinding and dispersion to form a certain carbon nanotube dispersion A;

[0029] The content of carbon nanotubes in the carbon nanotube dispersion liquid is 1-10%, the content of dispersion aids and dispersion stabilizers is 0-1%, and the rest is solvent.

[0030] 2. Disperse a certain amount of dispersant into the solvent, then add graphite and perform pre-dispersion treatment, that is, firstly stir evenly through simple mechanical stirring, and then shear and disperse through high-speed shearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com