Anode active material and preparation method thereof

A positive electrode active material, selected technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of unsatisfactory rate discharge performance, unstable material structure, poor conductivity, etc., the method is simple and easy to realize, crystal form Perfect, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a method for preparing the above-mentioned positive electrode active material. The steps include: a. mixing and ball milling the lithium source, the M source, the M' source, the fluorine source and the silicic acid source;

[0023] b. Ultrasonic treatment of the obtained material after ball milling in step a, followed by drying;

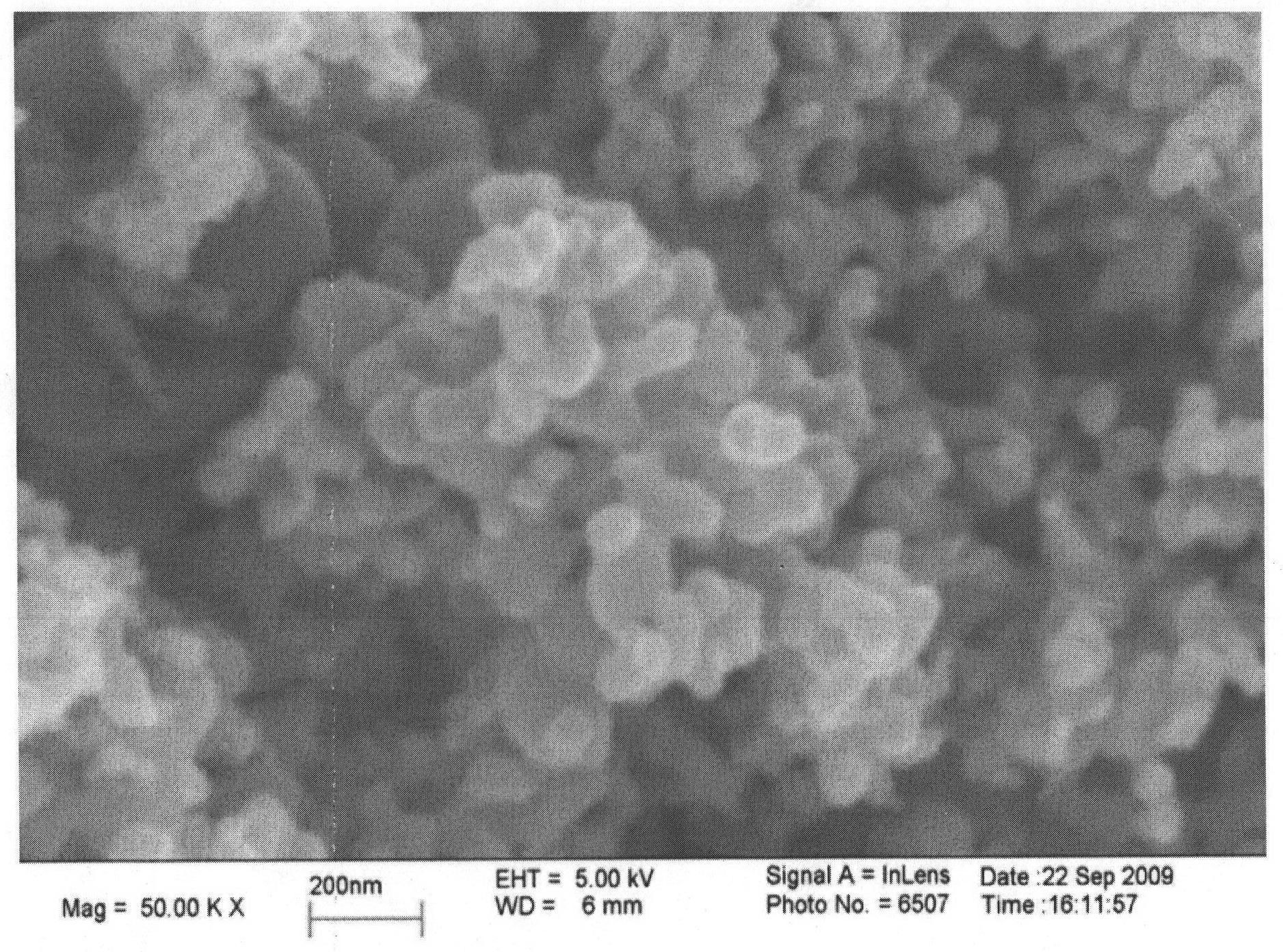

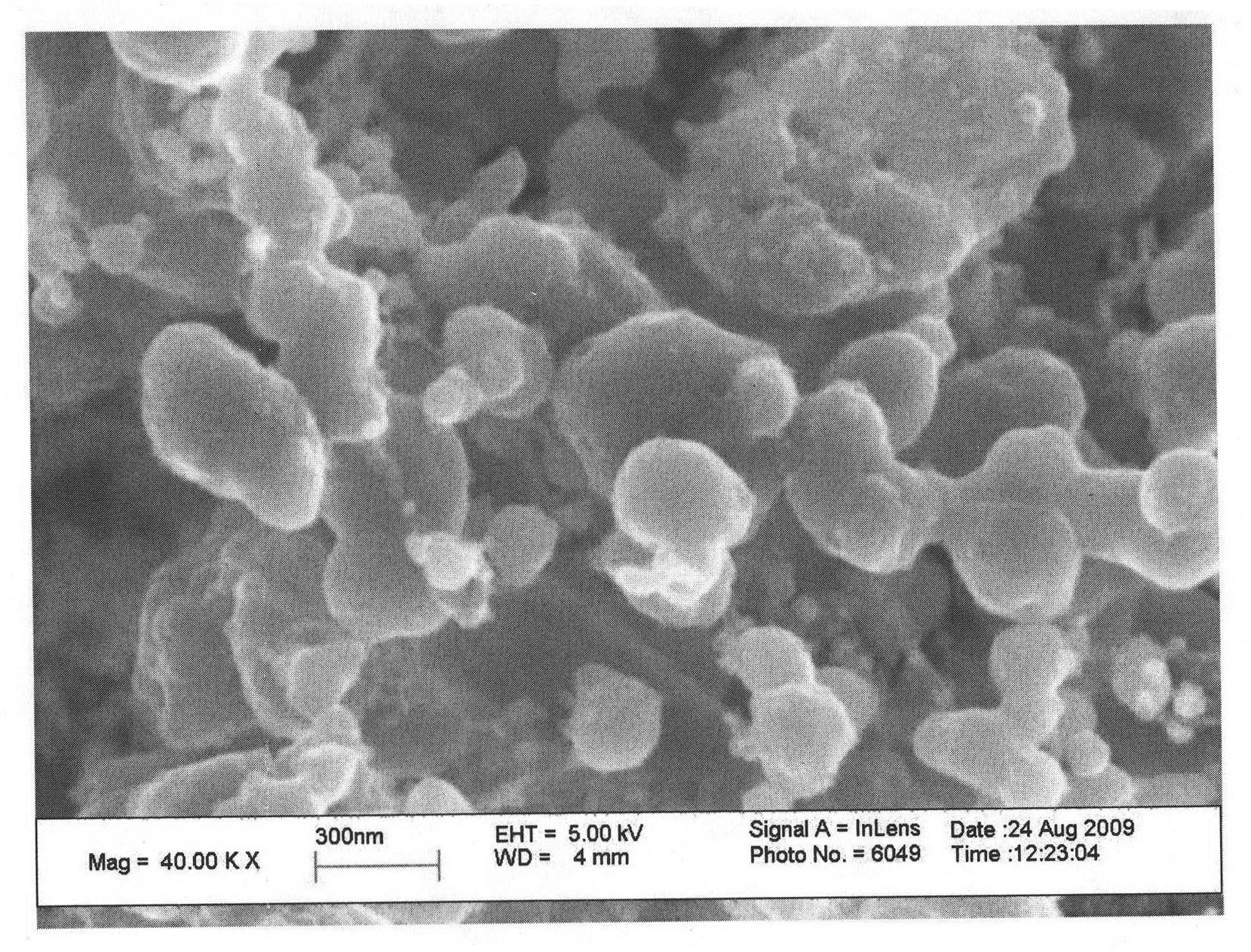

[0024] c. Sintering the substance obtained in step b under an inert atmosphere. The method is simple and easy to implement, and at the same time, the prepared material has excellent performance, stable structure, perfect crystal form, and can prepare nano particle material without agglomeration, and the particle size distribution of the material is uniform. The average particle diameter of the material particles prepared by the invention can be 100 nanometers, the average particle diameter is distributed between 50-200 nanometers, and the crystal form is perfect.

[0025] The molar ratio of Li: M: M': F: Si...

Embodiment 1

[0037] (1) Preparation of active materials

[0038] Take by weighing 40.96g of lithium acetate dihydrate, 2.87g of manganese carbonate, 31.48g of ferrous oxalate dihydrate, 1.04g of lithium fluoride, 41.66g of tetraethyl orthosilicate and 6.47g of glucose and mix them in 500ml of ethanol (the mixture of water and ethanol). The volume ratio is 1:1, and the pH value is 10) in a high-speed ball mill for 8 hours. Afterwards, the ball-milled slurry was ultrasonicated at 250W for 4 hours, and then spray-dried in an SD2Basic spray dryer of Engineering INC, Italy, and spray-dried at 120°C for 10 hours. Finally, the roasting heat treatment is carried out in a box-type atmosphere furnace. Under the protection of Ar gas, the temperature is kept at 650°C for 10h, the heating rate is 5°C / min, and the gas flow rate is 200ml / min. ℃ for 4 hours, then cooled to 550 at 5℃ / min and kept for 4 hours, then cooled to room temperature. Li can be obtained with furnace cooling 2 mn 0.125 Fe 0.875 ...

Embodiment 2

[0044] Active materials and simulated batteries were prepared in the same manner as in Example 1, except that the raw materials added were 40.96 g of lithium acetate dihydrate, 11.495 g of manganese carbonate, 17.99 g of ferrous oxalate dihydrate, and 41.66 g of ethyl orthosilicate. Lithium fluoride 1.04g to prepare Li 2 mn 0.5 Fe 0.5 SiO 3.96 f 0.02 active material.

[0045] The average particle size measured by the same method as in Example 1 is 50-150 nm, the distribution is uniform, the particle size is basically the same, and there is no agglomeration phenomenon. The crystal shape is perfect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com