Method for growing RFeO3 photomagnetic function crystal by secondary melting method

A ortho-ferrite, secondary melting technology, applied in the direction of self-area melting method, single crystal growth, crystal growth, etc., can solve the problems of not getting large crystal particles, less crystalline amount of melt, and small crystal size. , to achieve the effect of characteristic peak enhancement, crystal quality improvement and ideal uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: NdFeO 3 The specific steps of single crystal preparation are as follows:

[0022] A. Add high-purity Nd with a molar ratio of 1:1 2 o 3 with Fe 2 o 3 Weigh, grind for 8 h and mix evenly, and pre-calcine at 1000 °C for 12 h.

[0023] B. Put the polycrystalline powder obtained in A into a mold, press it into a rod shape with 70 MP isostatic pressing, and sinter it in a high-temperature furnace at 1200 °C for 24 h.

[0024] C. Crush and grind the polycrystalline rod obtained in B, put it into a mold, press it into a rod shape with 70 MP isostatic pressing, and sinter it in a high-temperature furnace at 1200 °C for 24 h.

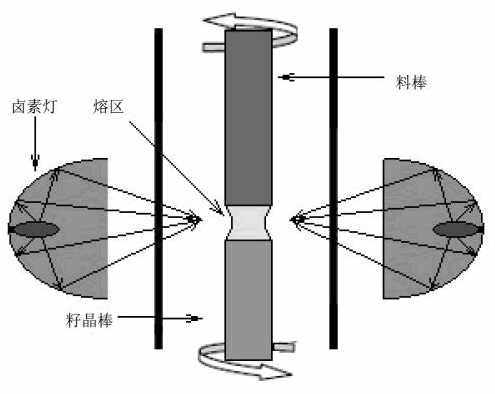

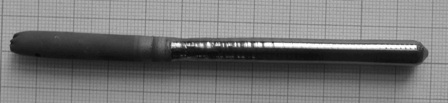

[0025] D. Place the obtained material rod in an optical floating zone furnace, grow crystals in an air atmosphere with a flow rate of 5 L / min, grow at a faster pre-melting speed of 15 mm / h, and the clockwise rotation speed of the material rod is 15 rpm, The seed crystal was rotated counterclockwise at 15 rpm, and after all crystal...

Embodiment 2

[0028] Embodiment two: ErFeO 3 Single crystal preparation is basically the same as Example 1, the difference is that the rare earth ion is Er 3+ , the air flow rate is 5 L / min, the pre-melting speed is 12 mm / h, and the secondary melting speed is 6 mm / h.

Embodiment 3

[0029] Embodiment three: HO 3 Single crystal preparation is basically the same as Example 2, the difference is that the rare earth ion is Ho 3+ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com