Nickel cobalt lithium aluminate positive electrode material as well as preparation method and application thereof

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of unsatisfactory electrochemical performance of lithium batteries, achieve excellent electrochemical performance, reduce weight loss, and dissociate The effect of low lithium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of preferred nickel cobalt lithium aluminate cathode material of the present invention, comprises the steps:

[0046] a) Mixing (physical dispersion), that is, lithium salts, nickel-cobalt-aluminum precursors, target dopant element raw materials, etc. are prepared by wet, dry or quasi-dry methods to prepare fluffy powder materials or materials that are slightly agglomerated locally . The lithium salt is composed of lithium carbonate, lithium hydroxide monohydrate, lithium acetate and / or lithium oxalate and the like.

[0047] b). First pulverization at high temperature (physical-chemical dispersion). The material obtained in step a) is introduced into a high-temperature pulverizer for further dispersion and pulverization to form a powdery material with uniform composition, while some raw materials undergo thermal decomposition reactions. High-temperature pulverizer refers to a pulverizer that uses high-temperature and high-pressure steam as the ai...

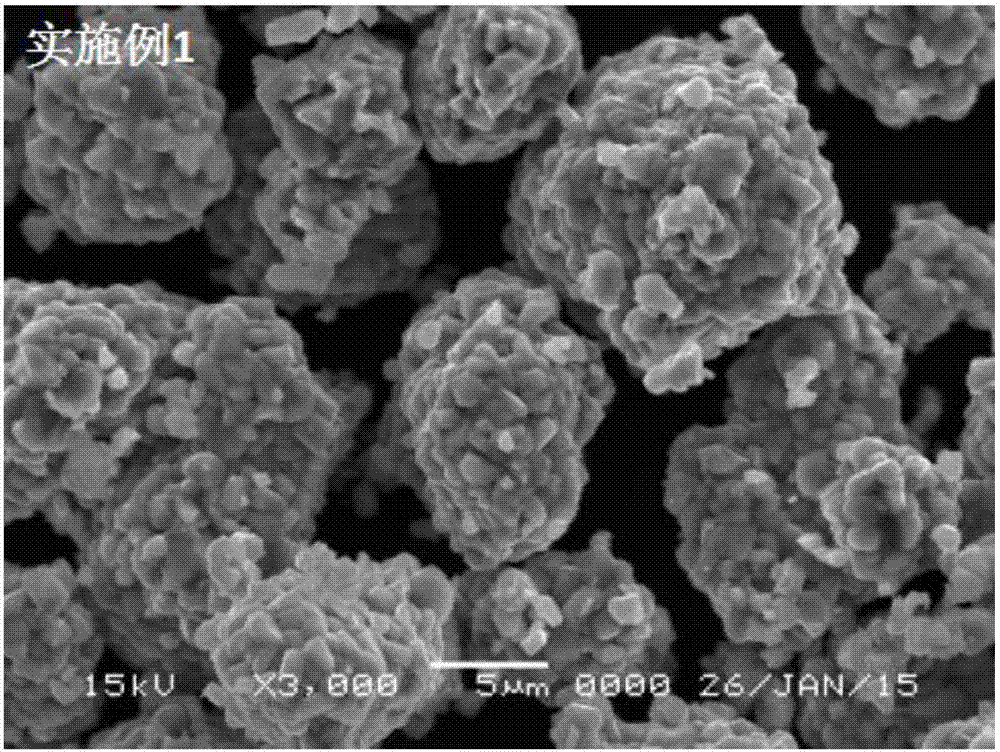

Embodiment 1

[0058] Embodiment 1 (comparative example)

[0059] Material mixing: use 1000L plow mixer. Turn on the stirring (rotating speed 25rpm), add 634.8kg of nickel-cobalt-manganese precursor (Ni 0.82 co 0.17 Al 0.01 (OH) 2 (grain size D v50 : 7 μm, effective substance content 99.5%), then take by weighing 252.3kg lithium hydroxide monohydrate powder (particle size D v50 : 25 μm, active matter content 99.8%) join in the mixer, add 222.0kg deionized water by 80wt% solid content under the stirring situation, further reduce speed (5rpm) after stirring 2h, stir 6h and discharge and form to have certain forming degree Paste materials are sealed for later use.

[0060] Primary sintering: use ventilated 24m roller kiln. Set the temperature in the heating zone to 400°C, under the condition of introducing oxygen-enriched air (oxygen-enriched air with an oxygen content of 45%, and a flow rate of 400m 3 / h) Put the material into the ceramic bowl for the first sintering, and sintering for...

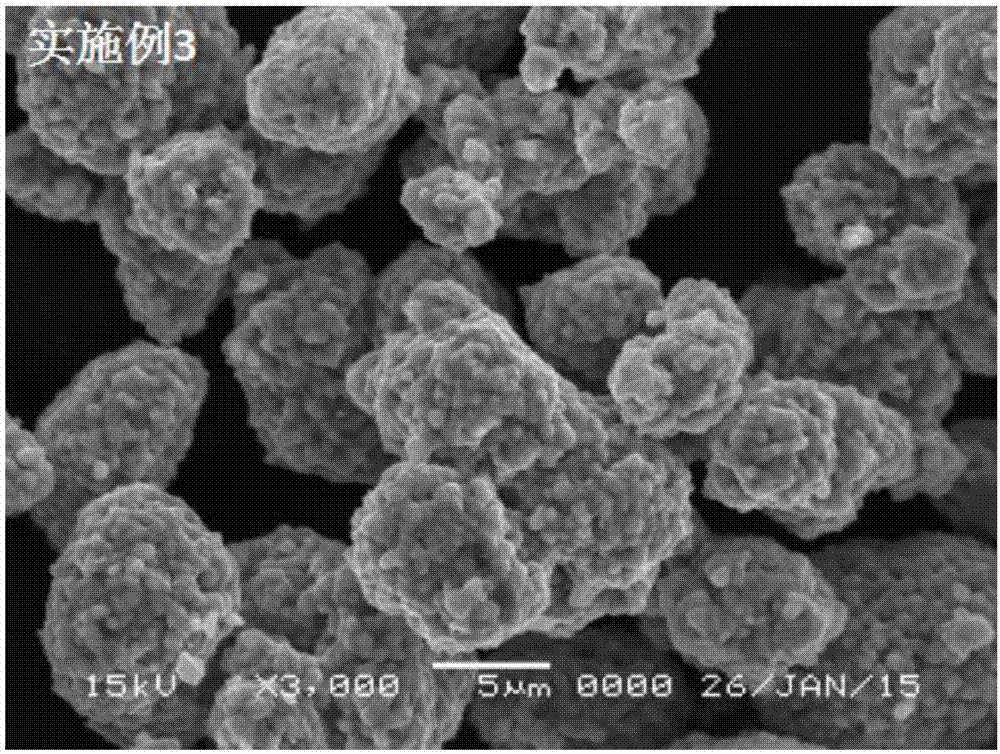

Embodiment 2

[0065] Embodiment 2 (comparative example)

[0066] Material mixing: use 1000LY mixer. Turn on stirring (speed 50rpm), add 317.4kg of nickel-cobalt-manganese precursor (Ni 0.82 co 0.17 Al 0.01 (OH) 2 (grain size D v50 : 7 μm, effective matter content 99.5%), then take by weighing 252.3kg lithium hydroxide monohydrate powder (particle size D v50 : 25 μm, active substance content 99.8%) join in the mixer, add 142.0kg deionized water by 80% solid content under stirring situation, and 0.56kg magnesium oxide (industrial grade, particle size D v50 0.5 μ m, purity 99.5%, content is 1000ppm in terms of finished product magnesium content), 0.83kg zirconium nitrate pentahydrate (industrial grade, purity 95%, content is 500ppm in terms of finished product zirconium content), after stirring 2h, further reduce speed (3 -5rpm) Stirring for 1 hour to form a paste-like material with a certain degree of molding, which is then discharged and sealed for later use.

[0067] Primary sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com