Positive electrode lithium supplementing material, positive electrode plate containing positive electrode lithium supplementing material and electrochemical device

A technology of positive pole piece and lithium supplementation, applied in the field of electrochemistry, can solve the problems of performance attenuation, slurry gelation, storage flatulence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068]

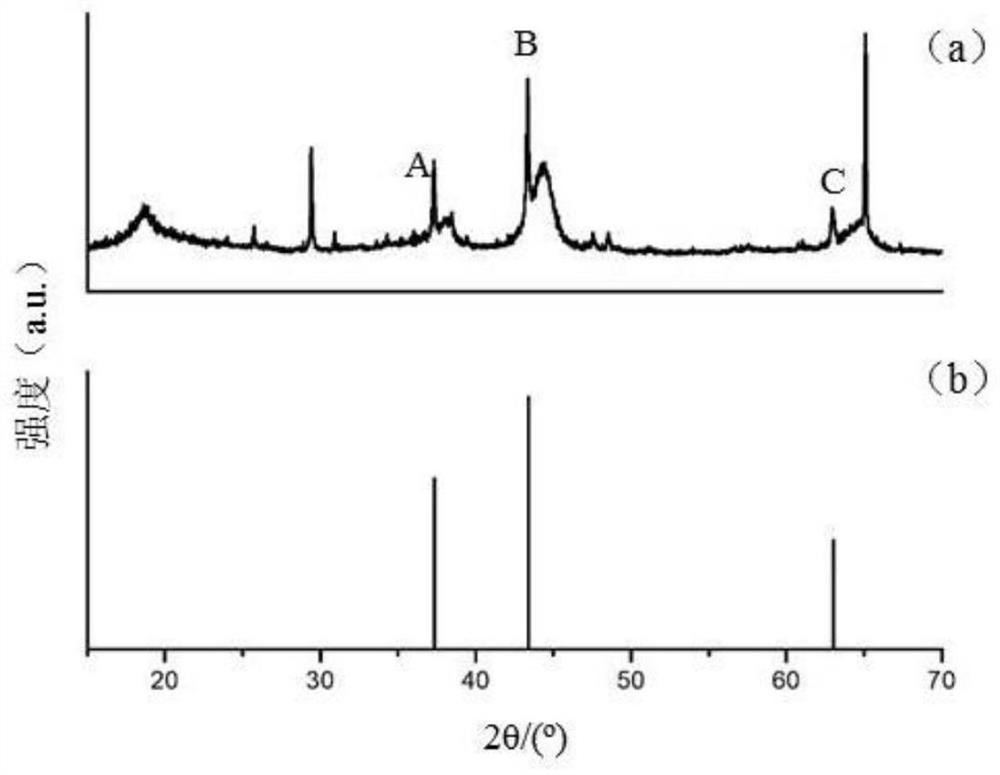

[0069] NiO and Li 2 O was mixed in argon at a mass ratio of 1:1, and ball milled for 24 hours to obtain a mixture. The mixture is compressed into pellets. Put the pellets into a nickel tube filled with argon and heat at 650 °C for 24 h to obtain the lithium-rich transition metal oxide Li 2 NiO 2 .

[0070] The lithium-rich transition metal oxide Li 2 NiO 2 Disperse in absolute ethanol, add silicon-containing material hexadecyltrimethoxysilane, stir magnetically to make it evenly mixed, filter with suction and dry to obtain a positive electrode lithium supplement material. Among them, the mass ratio of lithium-rich transition metal oxides to silicon-containing materials is 94.2:5.8; the average particle size Dv50 of the positive electrode lithium supplement material is 14 μm, and the specific surface area is 0.5m 2 / g; based on the total mass of the positive electrode lithium supplement material, the mass percentage of silicon in the surface layer is 0.5%.

[...

Embodiment 2

[0083] Example 2, Example 3, Example 4, Example 5, Example 6, Example 7, Example 8, Example 9, Example 10, Example 11, Example 12, Example 13, Example 14. In Example 15, Example 16, Example 17 and Example 18, , , , , , and the preparation steps are all the same as in Example 1, and the changes of relevant preparation parameters are as shown in Table 1:

[0084] Table 1

[0085]

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com