Lithium-ion battery positive electrode material prepared by rotary device and its preparation method and application

A technology for lithium-ion batteries and positive electrode materials, which can be applied to battery electrodes, positive electrodes, secondary batteries, etc., and can solve the problems of incapable of large-scale production and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

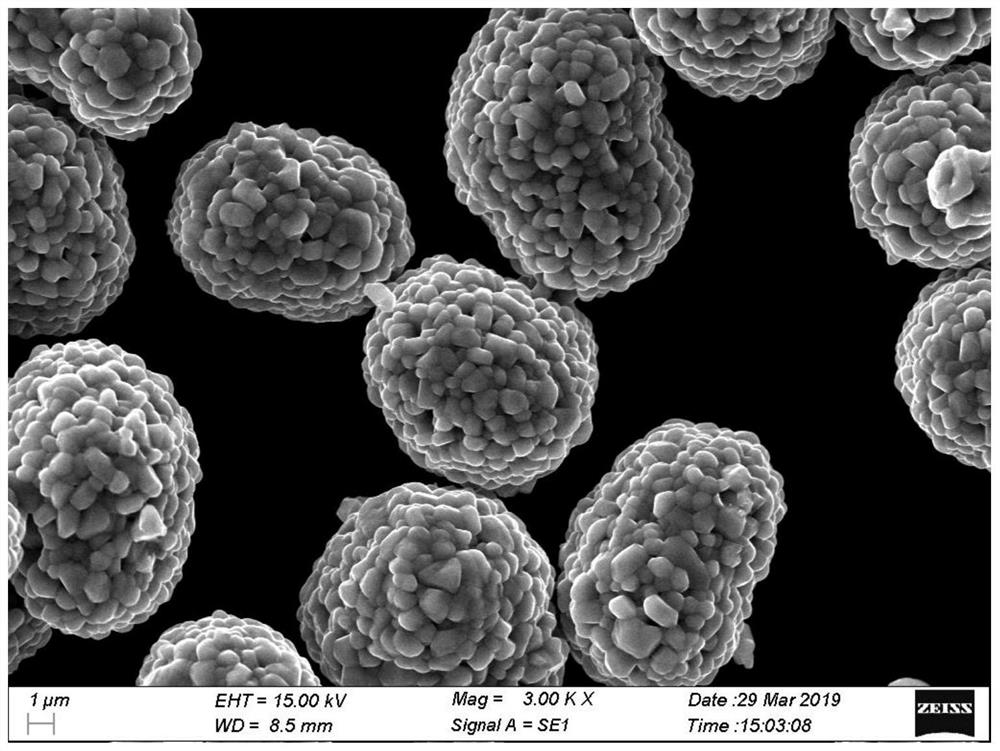

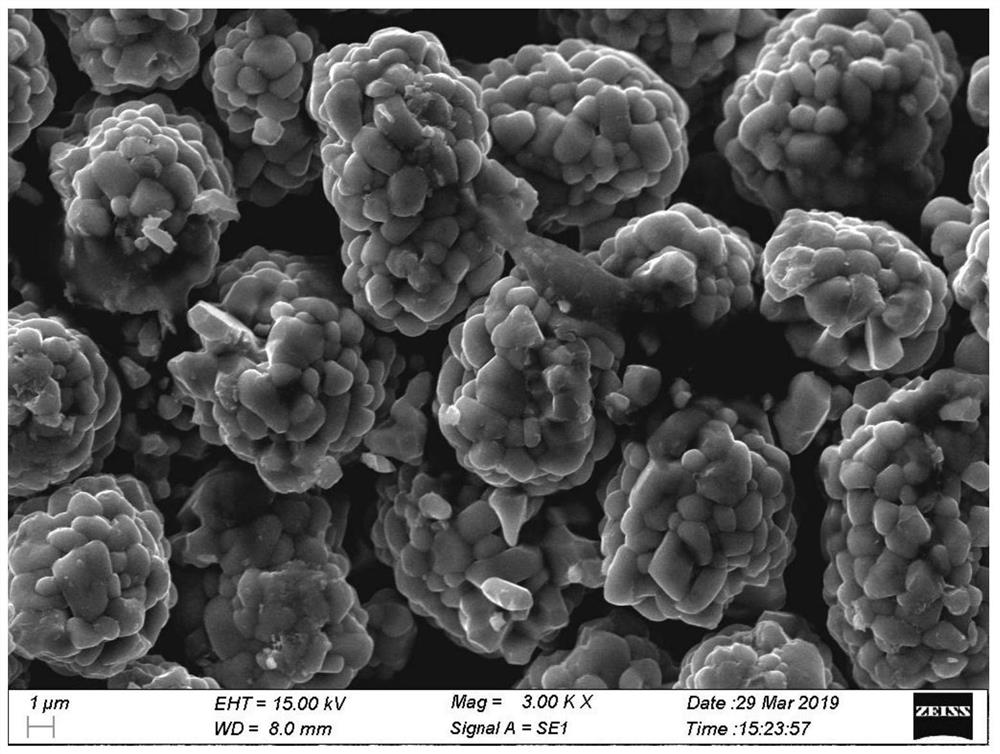

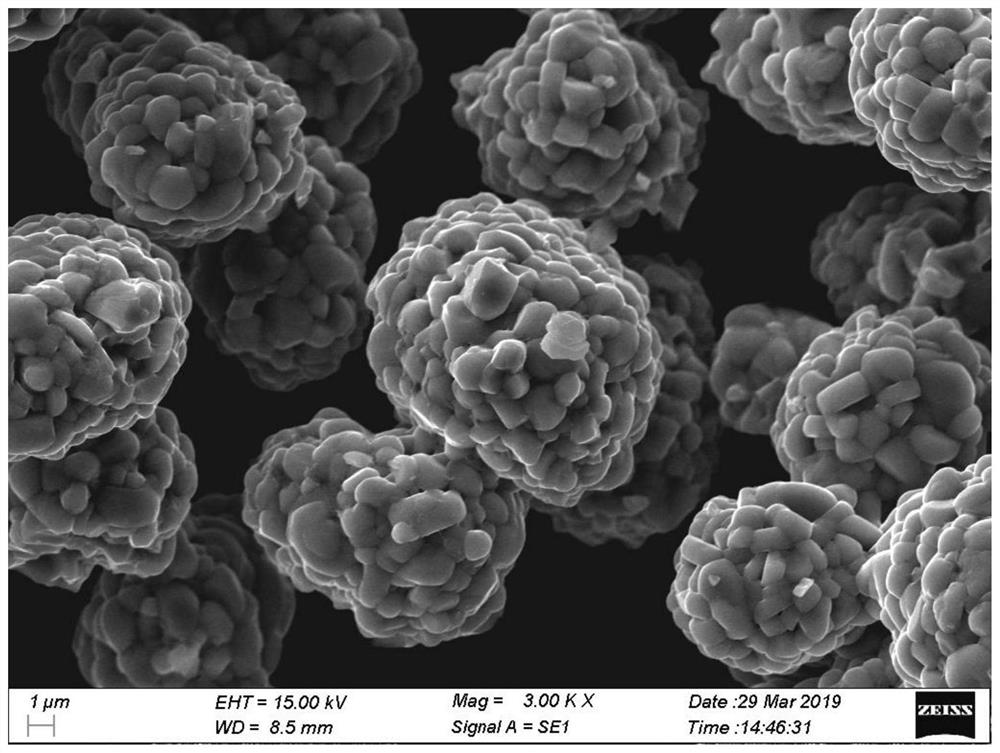

Image

Examples

preparation example Construction

[0064] In a preferred embodiment, the chemical formula of the high-nickel lithium ion positive electrode material of the present invention is Li x Ni a co b m c R d o 2 , wherein M is selected from manganese or aluminum, R is a doping element, 0.50<x<1.15, 0.55<a<0.95, 0.02<b<0.2, 0.01≤c<0.25, 0.98≤a+b+c≤ 1.05, 0≤d<0.1; the preparation method includes the following steps: mixing raw materials including nickel-cobalt-manganese precursor, lithium source compound or doping element R and high carbon content according to the metering ratio, dehydrating and using The ceramic-lined rotary kiln is sintered, and then pulverized to prepare the positive electrode material of the lithium ion battery. The invention is beneficial to replace the ceramic sagger used in the roller kiln or the pusher kiln, has the advantages of low energy consumption, increased production capacity and the like, and can realize large-scale production of high-nickel materials. The preparation method is econ...

Embodiment 1

[0092] Select a 1000L fusion machine, turn on the stirring (500rpm), and add 500kg of nickel-cobalt-manganese precursor (Ni 0.69 co 0.14 mn 0.16 (OH) 2 ), then weighed 231.5kg monohydrate lithium hydroxide powder and joined in the fusion machine, then weighed 0.30kg basic cobalt carbonate (300ppm by finished product quality), and added 190kg by 80wt% solid content under stirring to remove Ionized water, 7.4kg polyimide powder (1% by finished product mass), after stirring (300rpm) for 0.5 hours, further reduce the speed (50rpm) and stir for 20min and discharge to form a molded paste material for subsequent use.

[0093] Adopt ventilated 24m roller kiln. Set the temperature in the heating zone to 200°C, feed air (pressure 0.01Mpa, oxygen content volume ratio 40%, gas input 600Nm 3 Under the condition of / h), the above-mentioned pasty material is packed into the ceramic sagger for the first sintering, the sintering time is 5 hours, the material is isolated from the air and co...

Embodiment 2

[0099] Select 1000L coulter type mixer for use, start stirring (main shaft 120rpm, side knife speed 1300rpm), add 500kg nickel-cobalt-manganese precursor (Ni 0.6 co 0.19 mn 0.21 (OH) 2 ), then weighed 209kg of lithium carbonate powder and added it to a coulter type mixer, and added 3.85kg of tetrabutyl titanate (industrial grade, purity 98.5% content to about 1000ppm in terms of finished product titanium content) under stirring conditions, 29kg deionized water, 143kg spherical graphite (20% by finished product quality), after stirring (1300rpm) 2 hours, further reduce the speed (3-5rpm) and stir for 6 hours discharging to form the powdered material of molding for subsequent use.

[0100] The ventilation 15m rotary kiln is adopted. Set the temperature in the heating zone to 500°C, feed oxygen-enriched air (pressure 0.02Mpa, oxygen content volume ratio 99.5%, gas input 50Nm 3 Under the condition of above-mentioned pasty material under the condition of sintering for the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com