Machine-like stripping device for ton-scale production of graphene and production method of machine-like stripping device

A mechanical exfoliation and graphene technology, which is applied in the ton-level graphene-like mechanical exfoliation device and its production field, can solve the problems that restrict the industrialization process of graphene, the specific surface area is not too large, and there are many defects in graphene. The effect of perfect structure, good electrical conductivity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

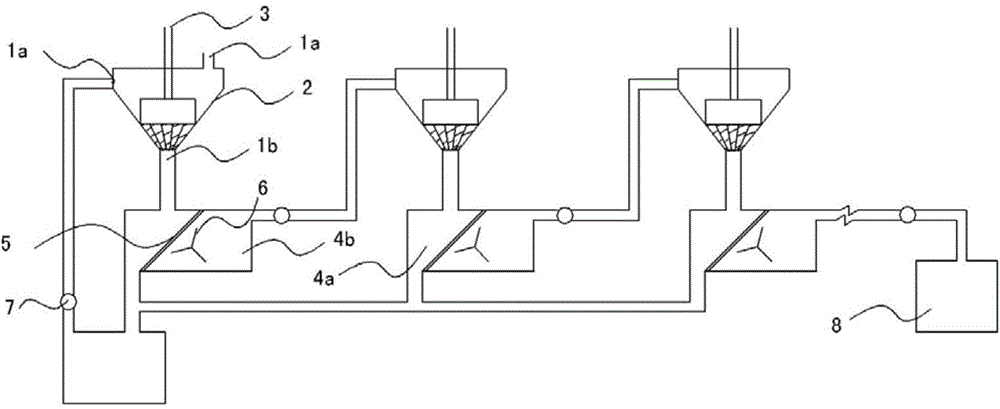

[0041] Such as figure 1 As shown, the quasi-mechanical stripping device for producing graphene at the ton level of the present embodiment is composed of three-stage stripping equipment connected in series;

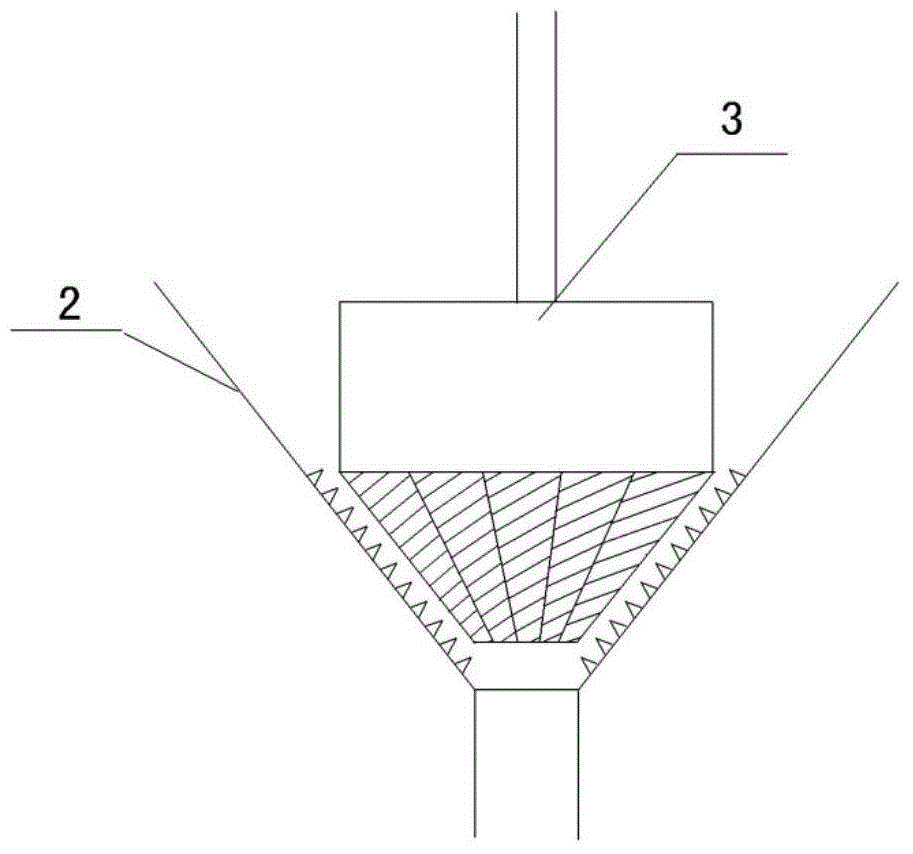

[0042] The structure of the stripping equipment is as follows: two feed ports 1a are arranged at the upper end of a material bin 2, and a discharge port 1b is provided at the lower end, and the lower part of the discharge port 1b is connected with the distribution bin, and a filter screen 5 is arranged in the distribution bin. , the filter screen 5 separates the sub-material bin into a coarse material bin 4a and a fine material bin 4b. After the material in the material bin 2 enters the sub-material bin through the discharge port 1b, it is filtered by the filter screen 5 and can enter through the filter screen 5. The fine material bin 4b, the material that does not pass through the filter screen 5 enters the coarse material bin 4a; a rotor 3 is arranged in the material bin...

Embodiment 2

[0060] When the quasi-mechanical stripping device of the present invention is only composed of one-stage stripping equipment, it can be simplified as a grinding disc structure, that is, the material bin 2 and the rotor 3 are equivalent to two circular marble grinding discs of a marble stone mill, and the contact surfaces of the two discs are set regular grooves such as Figure 6 shown. When in use, add 500g of flake graphite between two circular grinding discs with a diameter of 1m. While turning the grinding disc counterclockwise, add alcohol from the top of the grinding disc. There are regular grooves inside the upper and lower fans of the stone mill. , and the middle is deep and the outside is shallow, and there is still a certain gap in the middle. With the rotation of the upper fan mill, the graphite first enters the gap between the two grinding discs according to the engraved chute channel, and then gradually enters the regular groove. During this process, the van der W...

Embodiment 3

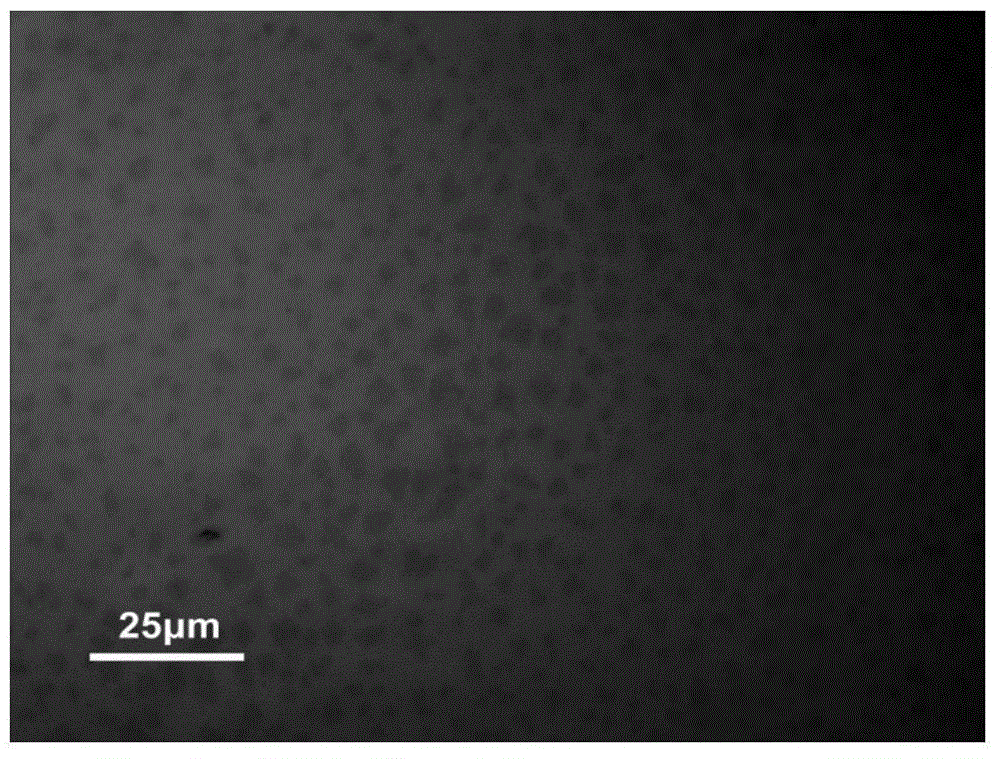

[0064] As a comparison, the present embodiment adopts chemical method to prepare graphene powder, specifically as follows: add 5mL oleum in a 250mL flask, add 2g graphite powder and 1g NaNO under stirring in an ice bath 3 After stirring the mixture evenly, add 6g of potassium permanganate three times, during which the temperature should not exceed 20°C. Continue stirring until the temperature rises to 35°C, continue stirring for 30 minutes, add deionized water, stir for another 20 minutes to make the solution uniform, add 5mL hydrogen peroxide, at this time the solution gradually turns bright yellow, filter while it is hot, and wash the obtained product with 5% hydrochloric acid successively Wash with deionized water until the solution is neutral, put the cleaned product into a vacuum drying oven and dry at 60° C. to obtain graphite oxide. Take 100mg of graphite oxide and disperse it in 100mL of water to obtain a brown-yellow suspension, put the liquid in an ultrasonic cleaner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com