Synthesis method of high-silicon b-oriented ZSM-5 nanosheets

A synthesis method, the technology of ZSM-5, applied in the directions of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of complex synthesis process, high synthesis cost, high cost and the like, and achieve synthesis High yield, strong hydrothermal stability, and the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Dissolve 0.03 g of ammonia water, 0.08 g of potassium chloride and 0.16 g of sodium metaaluminate in 25 ml of pure water, stir to clarify, add 20 g of silica sol with a concentration of 20 wt% dropwise under stirring, and stir the resulting solution for 20 minutes It is a silica-alumina sol-gel solution. Add 1.5 g of octylamine template dropwise to the above-prepared silica-alumina sol-gel solution, stir for 30 minutes, then add dropwise 0.2 g of silicate-1 seed solution with a concentration of 5wt%, and stir for 30 minutes to obtain a solution as a precursor solution. Mix the prepared precursor solution with 50ml polytetrafluoroethylene fluoride at 180 o C for 30 hours of crystallization reaction, washing and drying after the reaction to obtain high-silicon b-oriented ZSM-5 nanosheet zeolite.

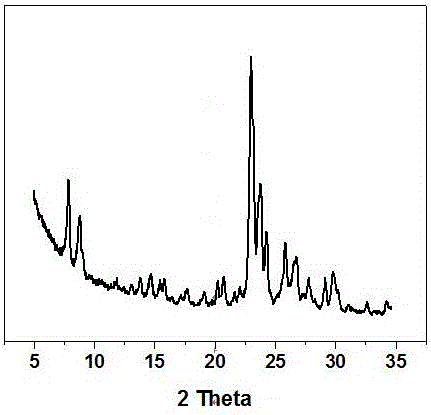

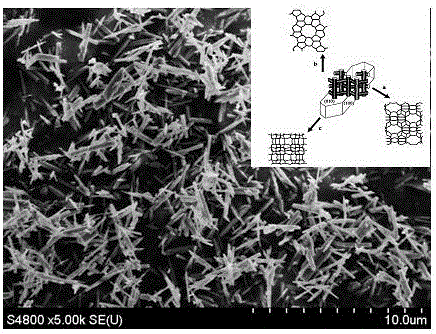

[0013] See attached figure 1 , the product obtained in Example 1 was measured by XRD characterization, and its crystal phase only had characteristic X-ray diffraction peaks a...

Embodiment 2

[0016] Dissolve 0.02 g of ammonia water, 0.08 g of potassium chloride and 0.16 g of sodium metaaluminate in 20 ml of pure water, stir to clarify, then add 20 g of silica sol solution with a concentration of 20wt% dropwise under stirring, and stir the resulting solution for 20 minutes It is a silica-alumina sol-gel solution. Add 4.8g of octylamine template dropwise to the silica-alumina sol-gel solution prepared above, stir for 30 minutes, then add 0.2 g of 5wt% silicate-1 seed solution dropwise, and stir for 25 minutes to obtain the precursor solution . Mix the prepared precursor solution with 50 ml of polytetrafluoroethylene fluoride at 180 o The crystallization reaction was carried out at the temperature of C for 25 hours, and after the reaction was completed, it was washed and dried to obtain a high-silicon b-oriented ZSM-5 nanosheet zeolite.

Embodiment 3

[0018] Dissolve 0.05 g of ammonia water, 0.05 g of sodium chloride and 0.1 g of sodium metaaluminate in 50 ml of water, stir to clarify, then add dropwise 20 g of a silica sol solution with a concentration of 20 wt% under stirring, and stir for 20 minutes to obtain a solution that is silicon Aluminum sol gel solution. Add 2 g of hexylamine template dropwise to the above-prepared silica-alumina sol-gel solution, stir for 30 minutes, then add dropwise 0.2 g of 5 wt% silicate-1 seed solution, and stir for 25 minutes to obtain the precursor solution . Mix the prepared precursor solution with 50ml polytetrafluoroethylene fluoride at 180 o C crystallization reaction at temperature C for 30 hours, washing and drying after the reaction to obtain high-silicon b-oriented ZSM-5 nanosheet zeolite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com