Method for preparation of faujasite from oil shale residue

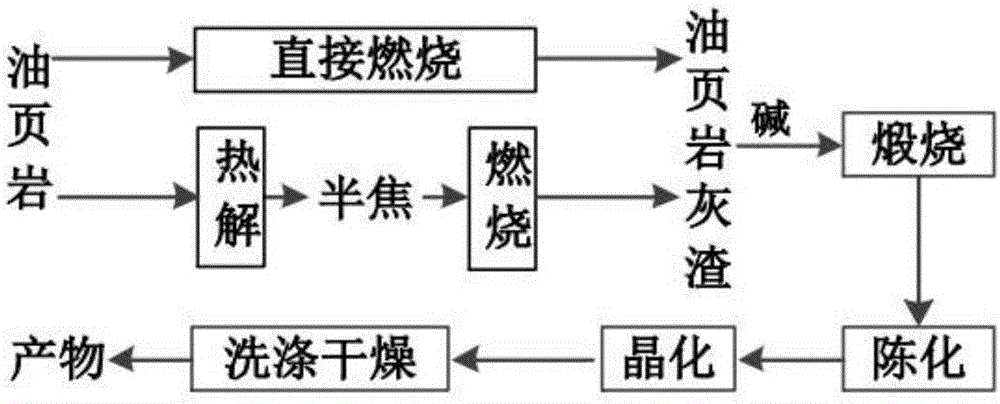

A technology for oil shale slag and faujasite zeolite, which is applied to faujasite crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of limited utilization, low added value and the like, and achieves simple process and low cost. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, a method for preparing faujasite from oil shale slag comprises the following steps:

[0019] Step 1: raw material selection, crushing and screening the ash obtained by burning oil shale in a circulating fluidized bed, and taking the oil shale slag below 200 mesh as the raw material for synthesizing zeolite;

[0020] Step 2: mixing and calcining, weighing 2g of oil shale slag for use in step 1, grinding and mixing with sodium hydroxide at a mass ratio of 1:1.2, and then calcining the mixture at 600°C for 1 hour;

[0021] Step 3: aging, fully grinding the calcined mixture in step 2, adding distilled water at a liquid-solid ratio of 4:1 (ml / g), and stirring at room temperature for 3 hours;

[0022] Step 4: crystallization, after sealing the aged product in step 3, crystallize at 80°C for 24 hours;

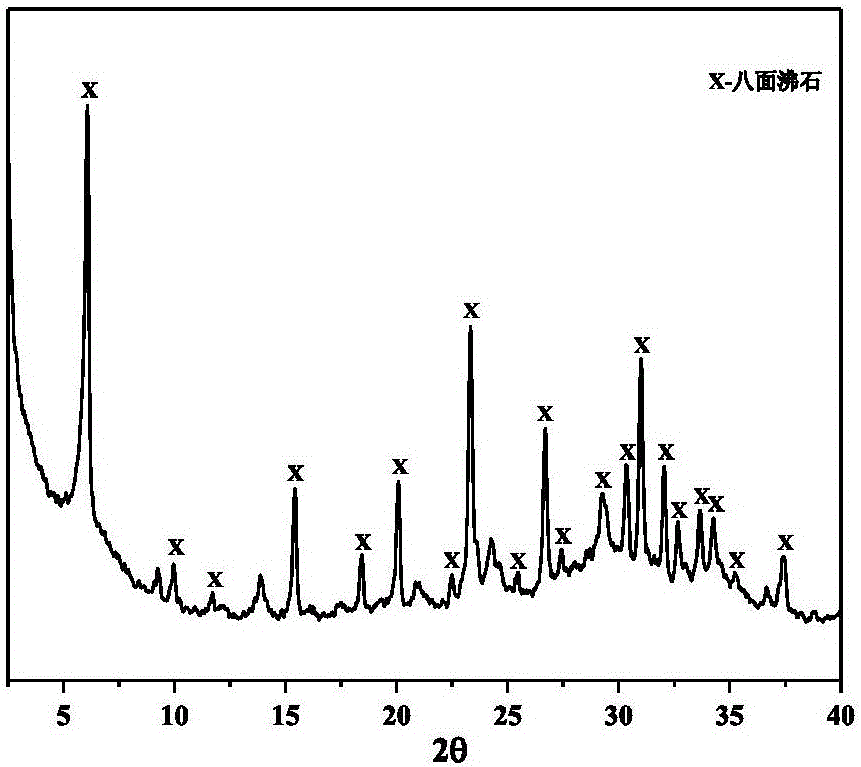

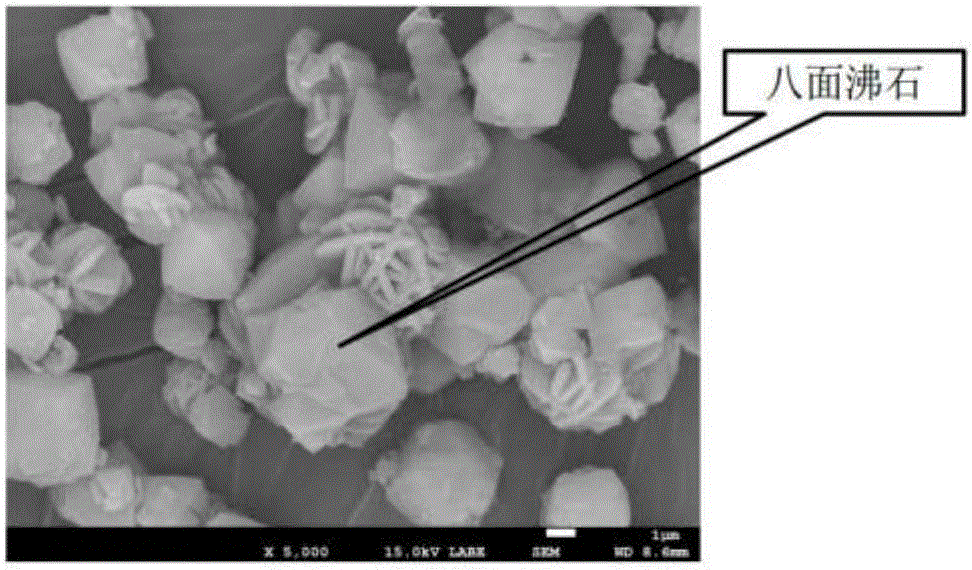

[0023] Step 5: washing and drying, washing the crystallized product obtained in step 4 with distilled water until the pH value of the washing solution is 7...

Embodiment 2

[0025] This embodiment is a method for preparing faujasite from oil shale slag, the steps are the same as in Example 1, the difference is that step 1 is the ash obtained after burning oil shale pyrolysis semi-coke in a circulating fluidized bed, In step 4, crystallize at 90° C. for 24 hours after sealing, and the calculated crystallinity of the synthesized faujasite is about 55%.

Embodiment 3

[0027] This embodiment is a method for preparing faujasite from oil shale slag, the steps are the same as in Example 1, the difference is that the raw material in step 1 is the ash slag directly burned from oil shale and the ash slag from oil shale pyrolysis semi-coke combustion In step 3, distilled water was added at a liquid-solid ratio of 5:1 (ml / g), and stirred at room temperature for 6 hours, and the obtained faujasite product had a crystallinity of about 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com