Cathode active material for lithium secondary batteries with high safety and method of preparing for the same and lithium secondary batteries comprising the same

一种阴极活性材料、锂蓄电池的技术,应用在用于材料和表面科学的纳米技术、锂蓄电池、电极制造等方向,能够解决导电性破坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067]

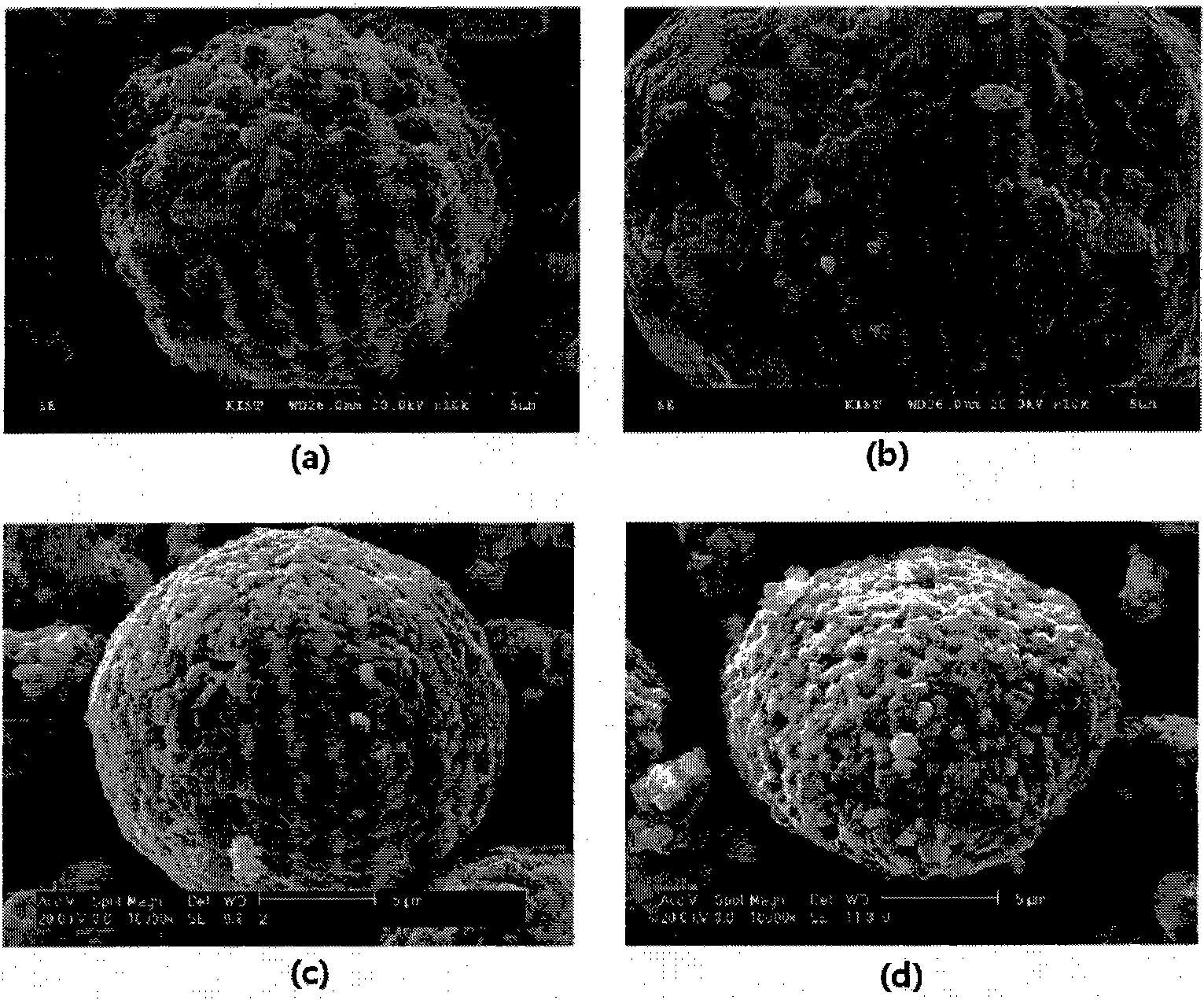

[0068] nickel sulfate (NiSO 4 ·6H 2 O), magnesium sulfate (MnSO 4 ·H 2 O) and cobalt sulfate (CoSO 4 ·7H 2 O) was dissolved in purified ion-exchanged water so that the molar ratio of nickel, cobalt and magnesium was 0.5:0.2:0.3, thereby preparing a metal solution. Separately, prepare sodium hydroxide and ammonia solutions.

[0069] Using a co-precipitation reactor at pH 11.2 and 400 rpm, the metal solution was supplied at a rate of 5 L / hr and the ammonia solution was supplied at a rate of 0.5 L / hr by a quantitative pump under an inert nitrogen atmosphere. Add sodium hydroxide solution intermittently, so that the solution in the reactor can maintain a stable pH of 11.2.

[0070] The reaction was carried out over 48 hours to obtain a slurry comprising metal composite hydroxides of regular size. A centrifugal separator type filter was used to wash and filter the slurry until the filtrate had a pH of 9.0 or lower, and then the obtained metal composite hydroxide p...

Embodiment 2

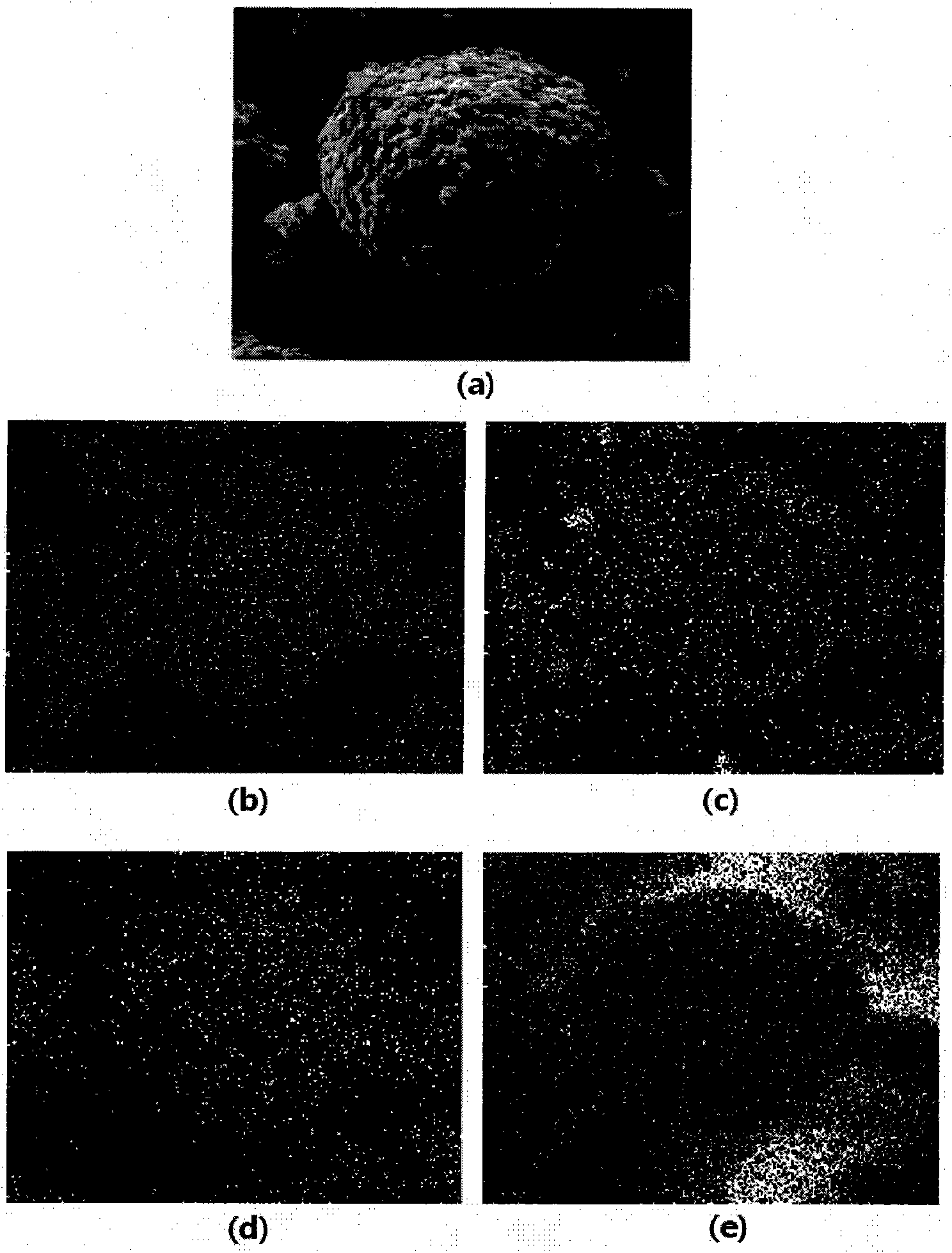

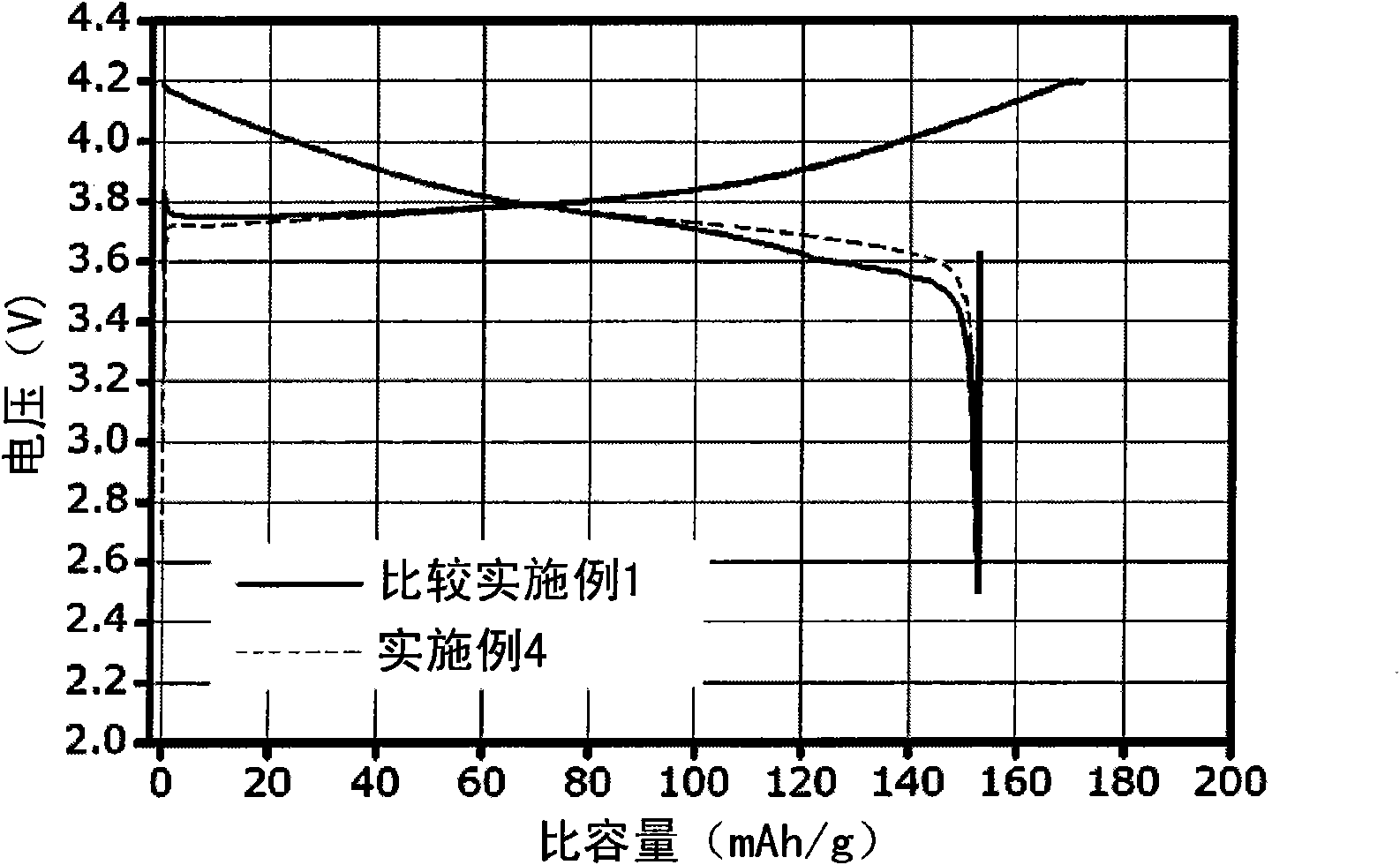

[0076] A cathode active material was prepared in the same manner as in Example 1, but barium titanate was set at 0.2 parts by weight based on 100 parts by weight of the core.

Embodiment 3

[0078] The cathode active material was prepared in the same manner as in Example 1, but in addition to barium titanate and titanium oxide to construct the shell, an additional 1.5 parts by weight of the average diameter D was added based on 100 parts by weight of the core. 50 150nm olivine-type lithium iron phosphate oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com