Manganese doped barium titanate thin film compositions, capacitors, and methods of making thereof

a technology of manganese doped barium titanate and composition, applied in the direction of thin/thick film capacitor, fixed capacitor details, fixed capacitors, etc., can solve the problems of low current density, power overshoot, and low leakage current under applied bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

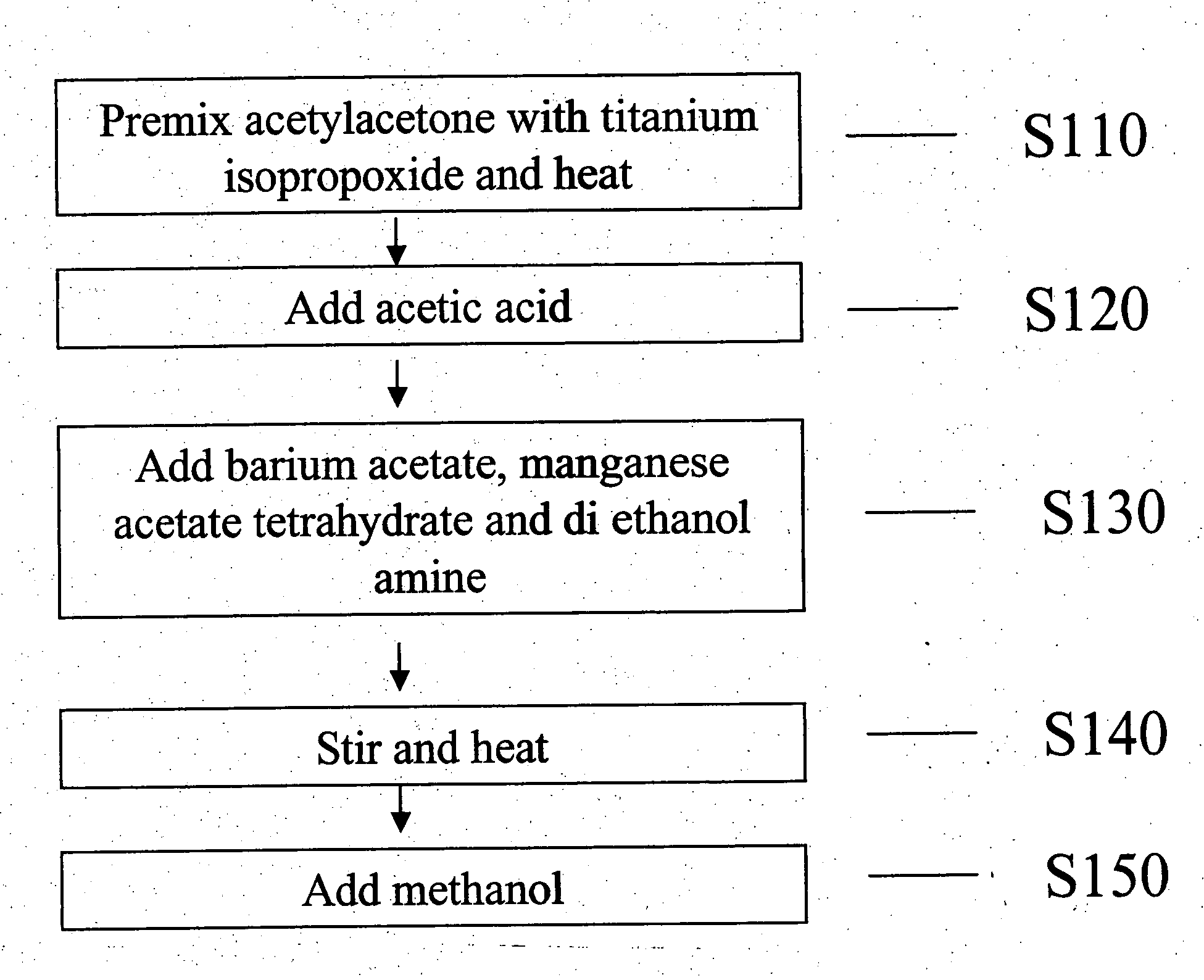

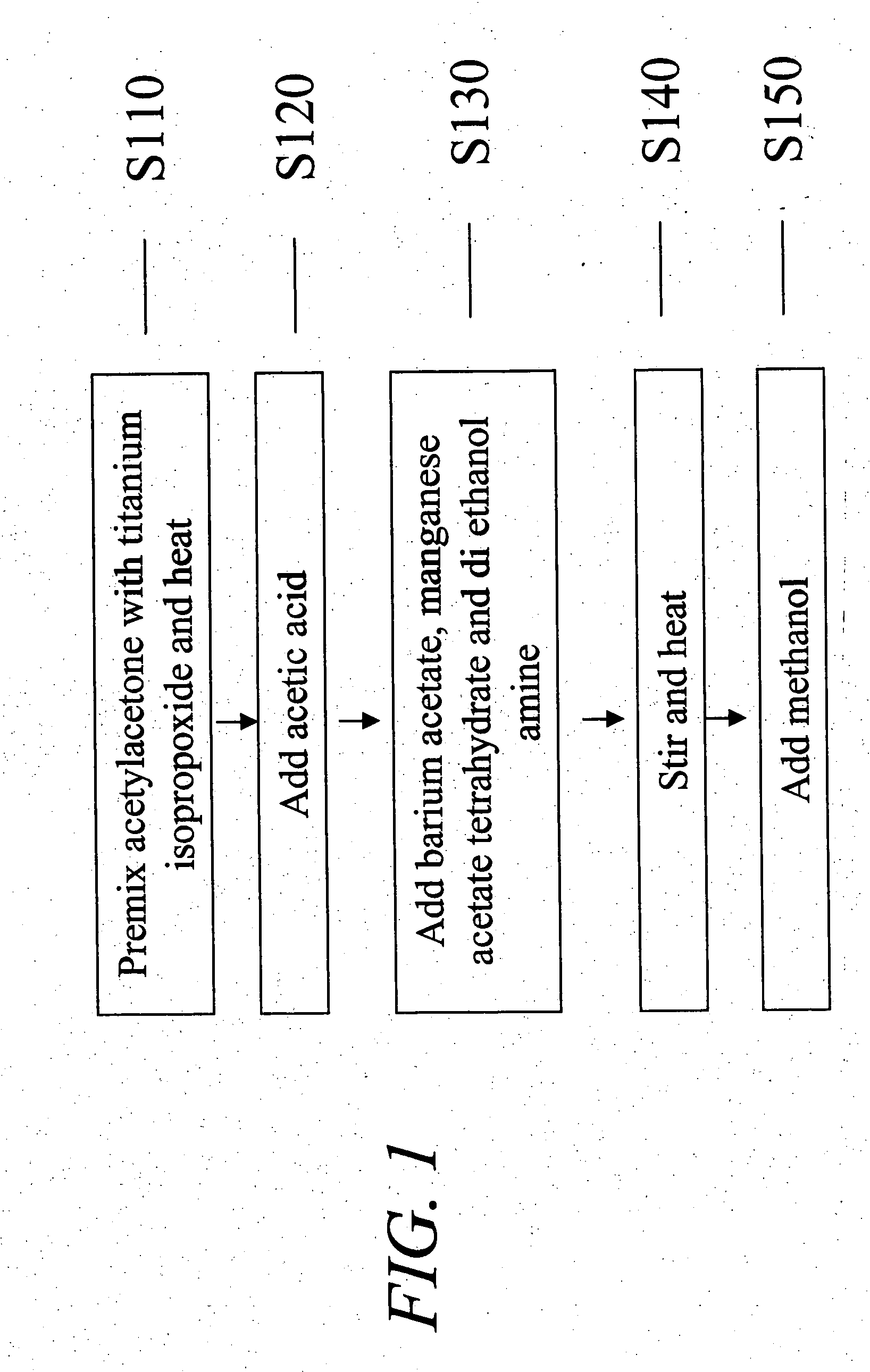

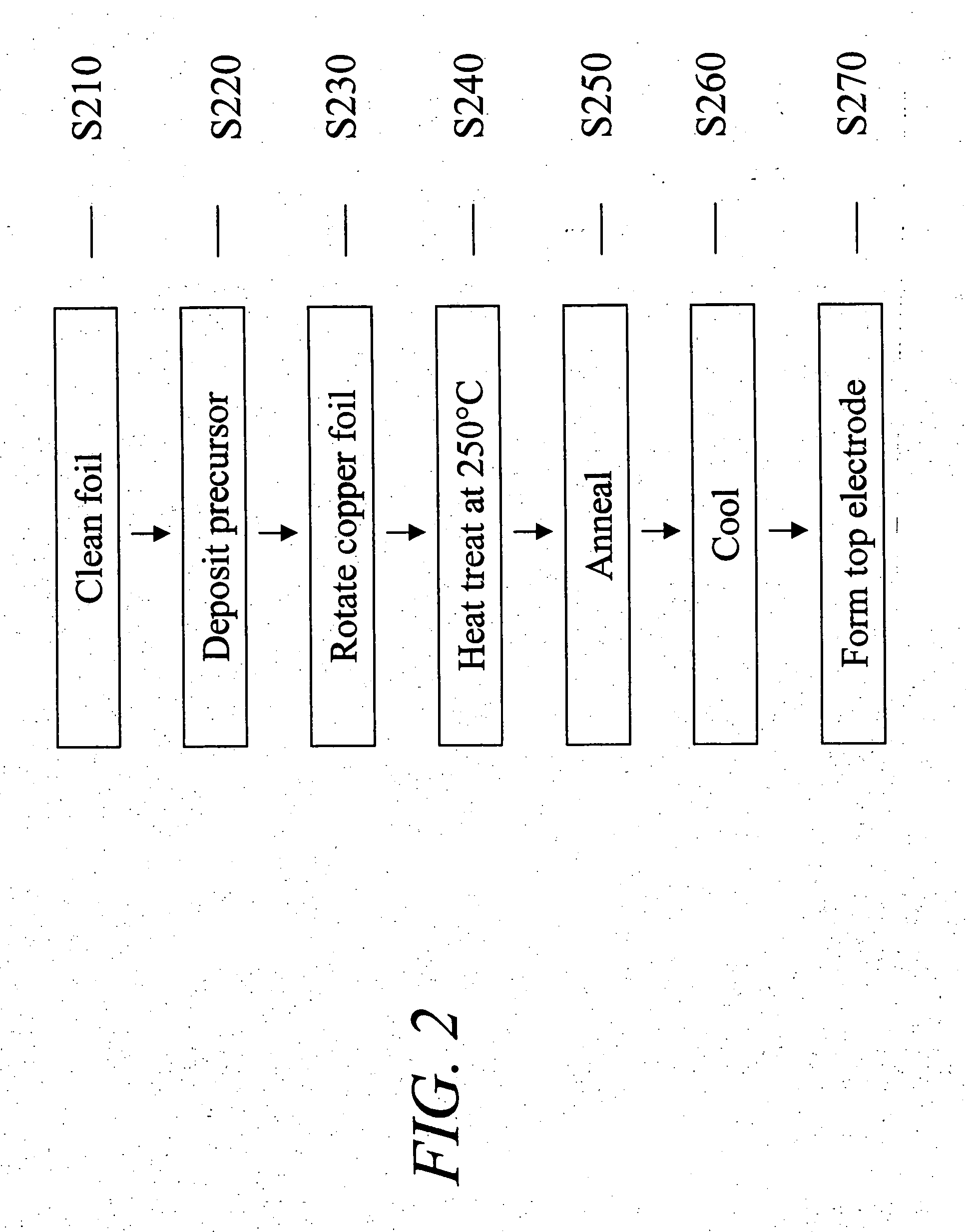

[0050] A thin film un-doped pure barium titanate film was prepared on a copper foil using a precursor as disclosed in U.S. National patent application Ser. No. 10 / 621,796 (U.S. Patent Publication No. 2005-001185). The copper foil was coated with the dielectric precursor composition using the method outlined in FIG. 2. The composition of the dielectric precursor was as given below:

Barium acetate2.6gTitanium isopropoxide2.9mlAcetylacetone2.0mlAcetic acid10.0mlMethanol15ml

[0051] Three spin coats were applied. The coated copper foil was annealed at 900° C. for 30 minutes under a partial pressure of oxygen of approximately 10−11 atmospheres. After annealing, the pure barium titanate was re-oxidized by placing the foil in a vacuum chamber under an atmosphere of approximately 10−5 Torr of oxygen at 550° C. for 30 minutes. This condition was chosen to avoid significant oxidation of the copper foil while still providing oxygen for re-oxidation of the dielectric. After re-oxidation, a top p...

example 2

[0053] A thin film 0.01 atom percent manganese doped barium titanate film was prepared on a copper foil. The copper foil was coated with the dielectric precursor composition using the method outlined in FIG. 2. The composition of the dielectric precursor was as given below:

Barium acetate5.08gTitanium isopropoxide5.68mlAcetylacetone3.86mlAcetic acid21mlMethanol24.26mlManganese acetate0.002gDiethanolamine0.54g

[0054] The only difference in inorganic levels between example 1 and example 2 is the manganese. The diethanolamine is a stress reducing organic material and has no effect on the final inorganic composition. Three spin coats were applied. The coated copper foil was annealed at 900° C. for 30 minutes at a partial pressure of oxygen of approximately 10−11 atmospheres. A top platinum electrode was sputtered on to the dielectric and the electrical characteristics of the capacitor were measured.

[0055] As shown in FIG. 5, the doped barium titanate layer without re-oxidation exhibite...

example 3

[0056] A 0.02 atom percent manganese doped barium titanate thin film was prepared on a copper foil in the similar manner described in EXAMPLE 1 using the precursor solution described below except the coating / pre-baking process was repeated six times. The manganese dopant solution was prepared by dissolving Mn(OAc)2 (0.2 g) in hot acetic acid (29.8 g):

Barium acetate 2.0 gTitanium isopropoxide2.22 gAcetylacetone1.56 gAcetic acid17.0 gDiethanolamine0.21 gManganese dopant solution0.17 g

[0057] The capacitance density and loss tangent for a manganese doped barium titanate layer without re-oxidation are shown in FIG. 7. The capacitance density was approximately 1.4 μF / cm2 at 0 volt and the loss tangent was 2 at 10 volts bias or approximately 1,000,000 times lower leakage current flow versus the re-oxidized undoped barium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com