Mounting and dismantling device for dampers of high-voltage transmission lines

A technology for high-voltage transmission lines and dismantling devices, which is applied to metal processing equipment, manipulators, metal processing, etc., can solve the problems of late research, low efficiency, and immature technology, and achieve good results, high efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

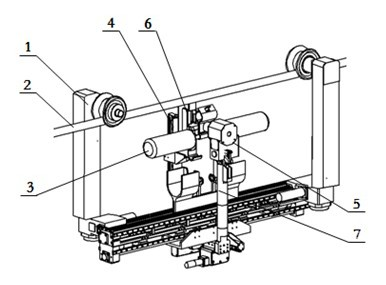

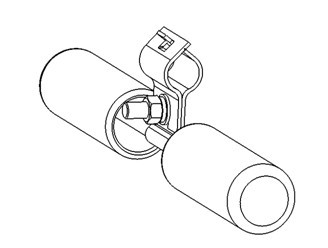

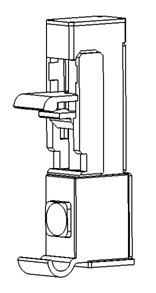

[0024] The device for installing and dismounting the anti-vibration hammer of the high-voltage transmission line of the present invention includes one end which is set on the walking robot 1 through the driving mechanism of the clamping mechanical arm and which can perform horizontal reciprocating and vertical up and down movements under the drive of the driving mechanism of the clamping mechanical arm. The clamping mechanical arm 4 and one end are arranged on the walking robot 1 through the nut-twisting mechanical arm driving mechanism and can perform horizontal reciprocating and vertically moving up and down under the drive of the nut-twisting mechanical arm driving mechanism 5; The other end of the holding mechanical arm 4 is provided with a clamping end assembly; the other end of the nut-twisting mechanical arm 5 is provided with a nut-twisting end assembly.

[0025] The clamping end assembly includes a clamping end box body 6, a clamping mechanism arranged in the clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com