20-roll rolling mill comprising upper and lower splitting integrated roll box and method for replacing rolls thereof

A rolling mill and roll box technology, applied in the field of pressure processing of metal materials, can solve the problems of small working roll diameter, difficult manufacturing, complex mechanism, etc., achieve simple and fast disassembly time, good resistance to deflection deformation, and reduce The effect of teardown time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

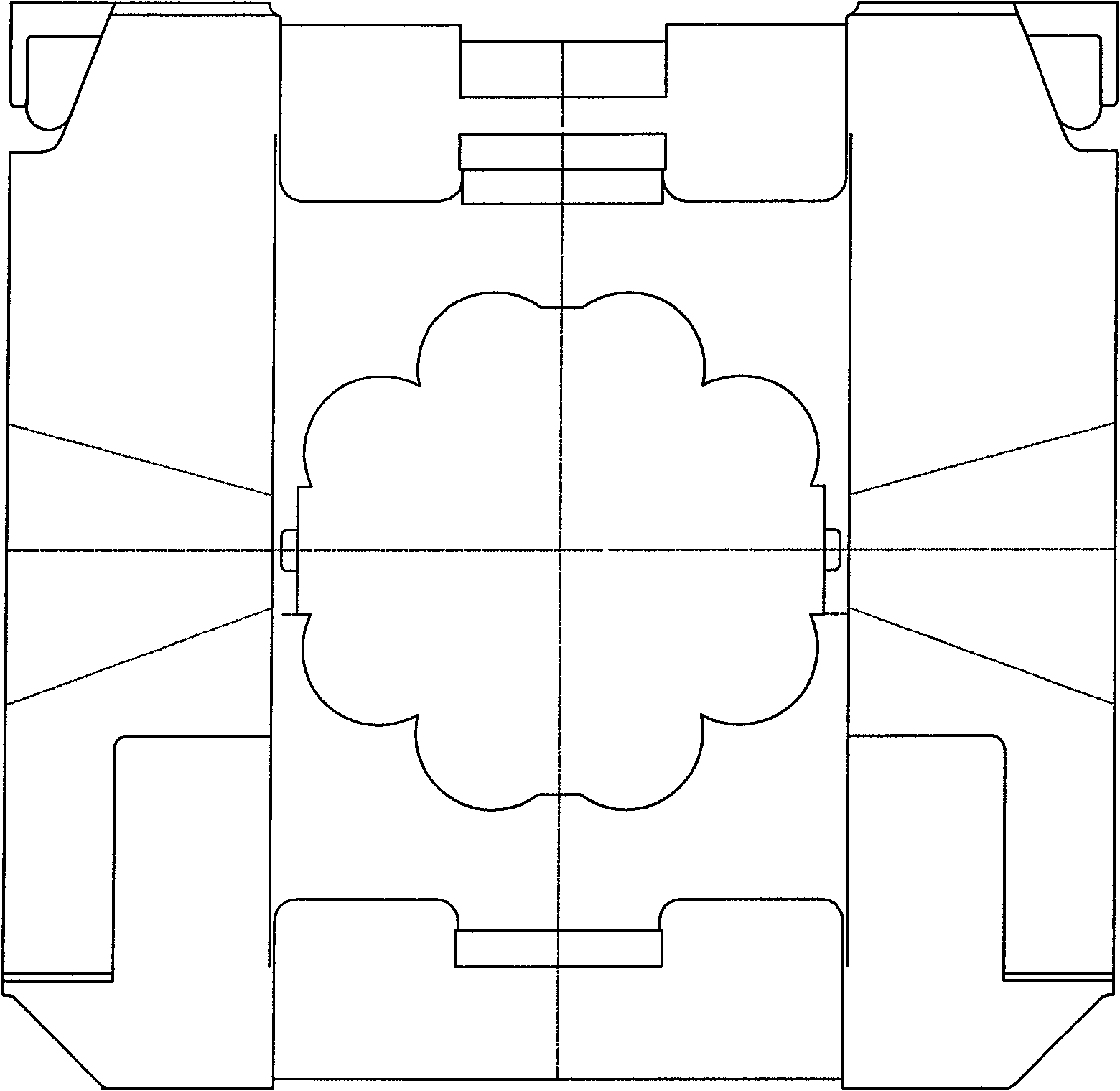

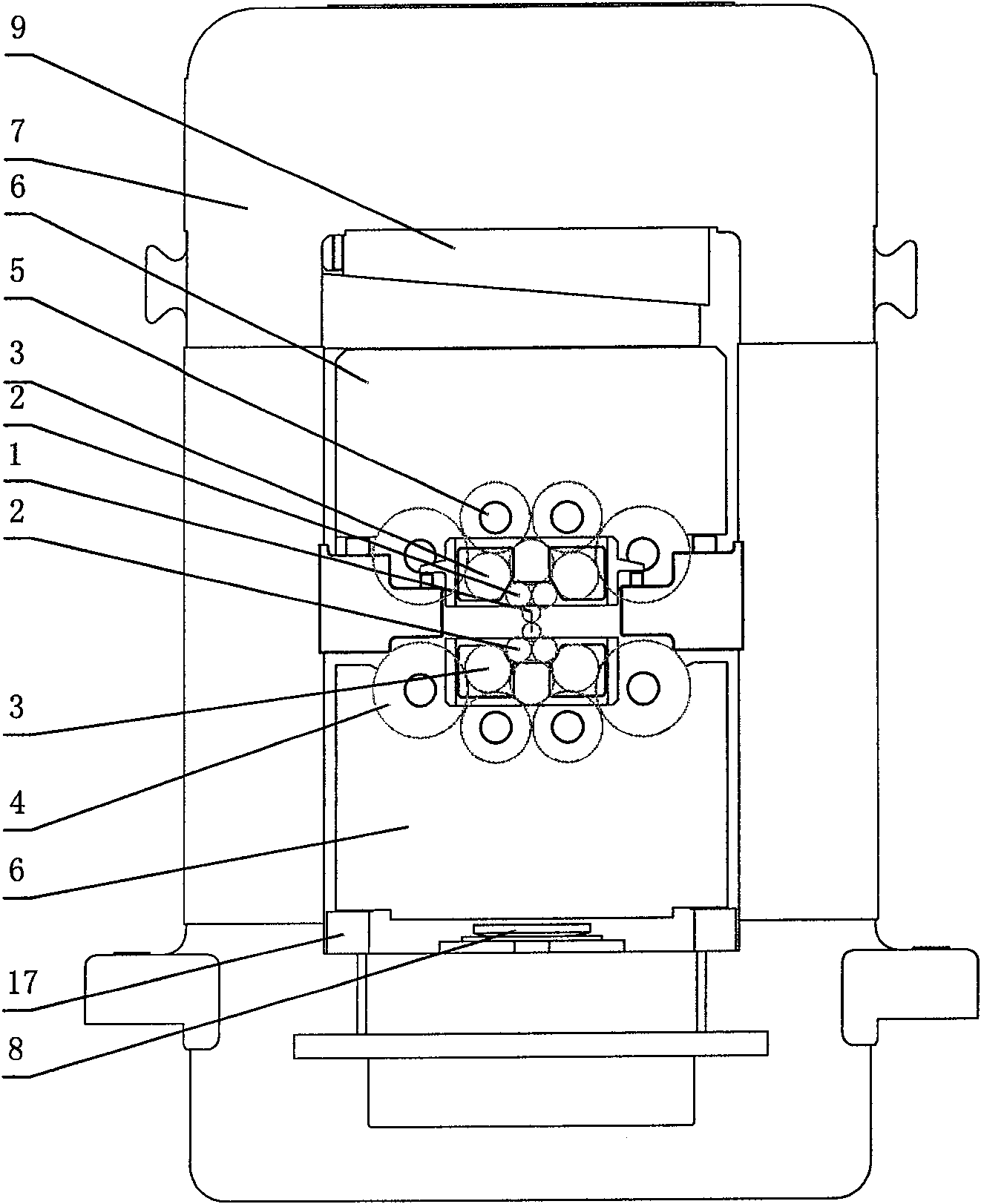

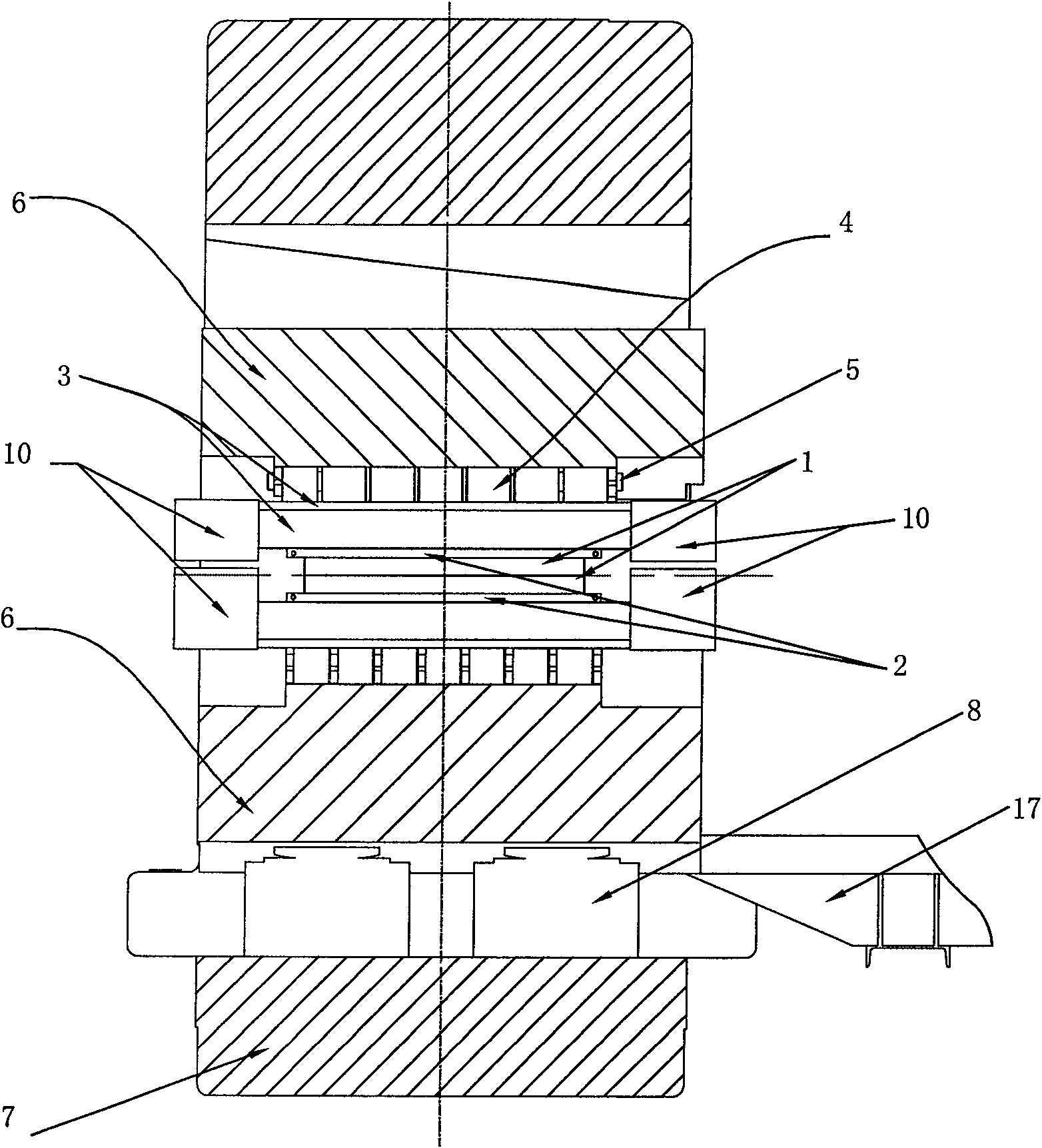

[0033] like figure 2 as shown, figure 2 The front view of the integral roll box type 20-roll rolling mill is divided up and down. It can be seen from the figure that the rolling mill is two independent roll boxes separated from the upper and lower, and the roll box 6 is an integral roll box. Using the semicircular groove processing technology, there is a partition that is still integrated with the roller box between the two adjacent semicircular grooves, which retains the square structure of the box instead of the old-fashioned semi-plum blossom-shaped concave hollow Box structure. The lateral rigidity of the two half-box working faces is stronger, the manufacturing cost is greatly reduced, and the weight of the entire rolling mill is reduced. The 20-roll rolling mill mentioned in the utility model has a 1-2-3-4 tower-shaped arrangement of rolls, including two small-diameter work rolls 1, 4 first-layer backup rolls 2, and 6 second-layer backup rolls 3 , 8 sets of backing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com