Pneumatic high-pressure oil filling device

A pneumatic high-pressure oiler technology, which is applied in the direction of engine components, engine lubrication, delivery pipes/joints, etc., can solve the problems of increased work intensity of operators, insufficient simplicity of the oiler gas circuit, and increased maintenance difficulty, etc., to achieve Convenient inspection and maintenance, reduced maintenance difficulty, convenient and easy connection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

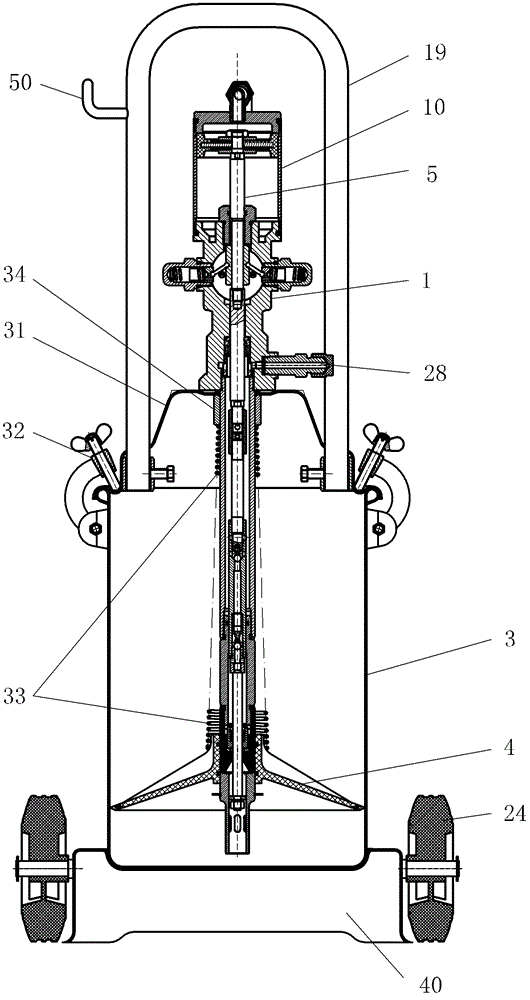

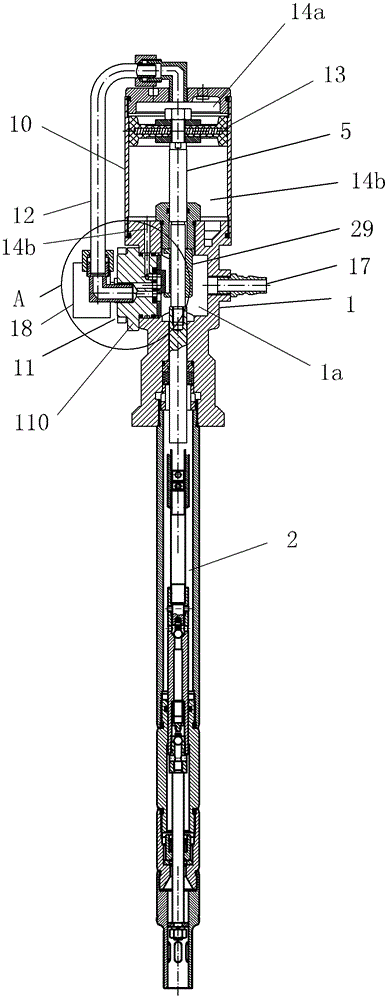

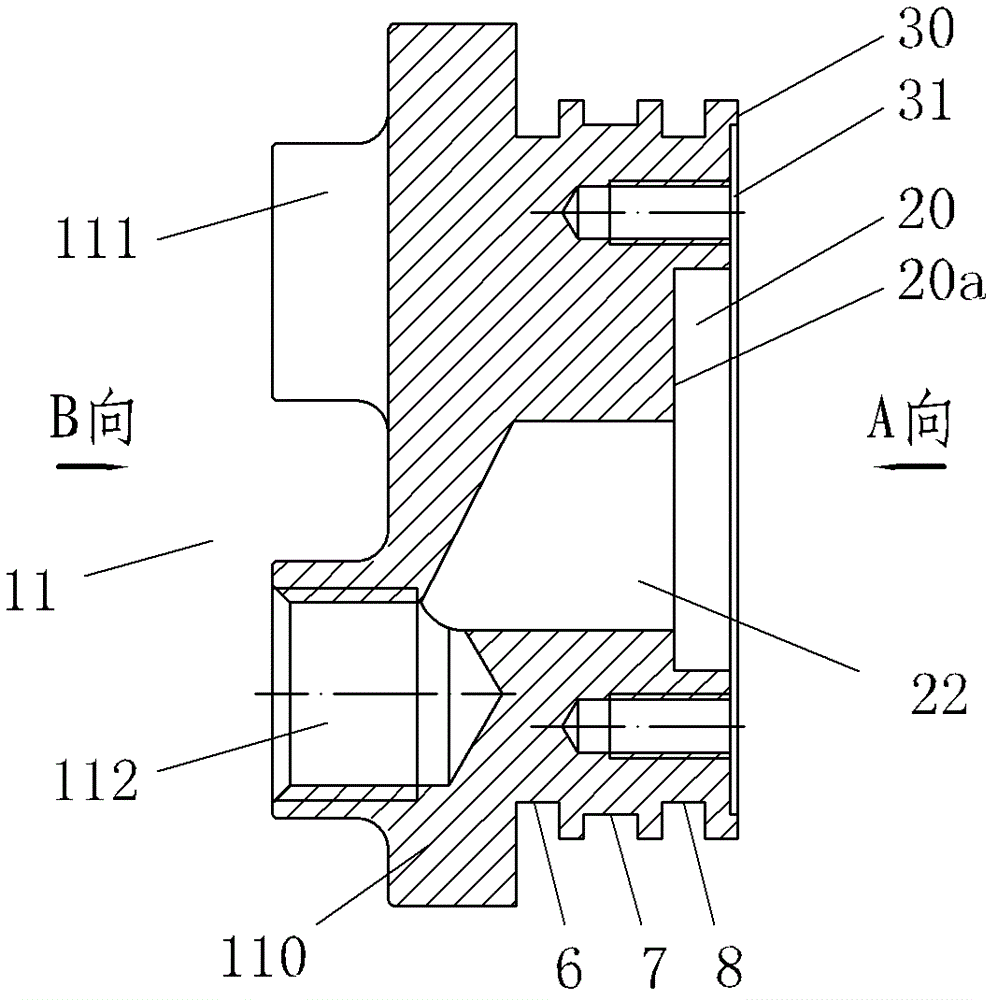

[0031] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-11 :

[0032] Pneumatic high-pressure oiler, including a barrel body 3 containing butter, an oil injection pump 1 arranged on the barrel body 3, and an oil injection gun (not shown in the figure) connected to the oil injection pump 1, and the oil injection pump 1 is supplied by a cylinder 10 pressurized by an air source The reciprocating movement drives the oil pressure plate 4 to continuously pressurize the butter entering the grease gun. The reciprocating movement of the piston rod 5 is realized by the automatic control of the reversing valve by the piston rod 5 on the cylinder 10. The reversing valve includes a distribution gas group Cover 11, the middle part of the distribution gas group cover 11 is provided with a mounting part 110, one side is provided with a conduit joint 111 and a muffler installation joint 112 side by side, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com