Deep sea mineral resource exploration system

A technology of mineral resources and deep sea, applied in the fields of mining minerals, earth-moving drilling, special mining, etc., can solve the problems of time-consuming disassembly and assembly, difficult maintenance, and high operation requirements, so as to prolong the service life, reduce the difficulty of disassembly and assembly, and reduce disassembly and assembly. The effect of loading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

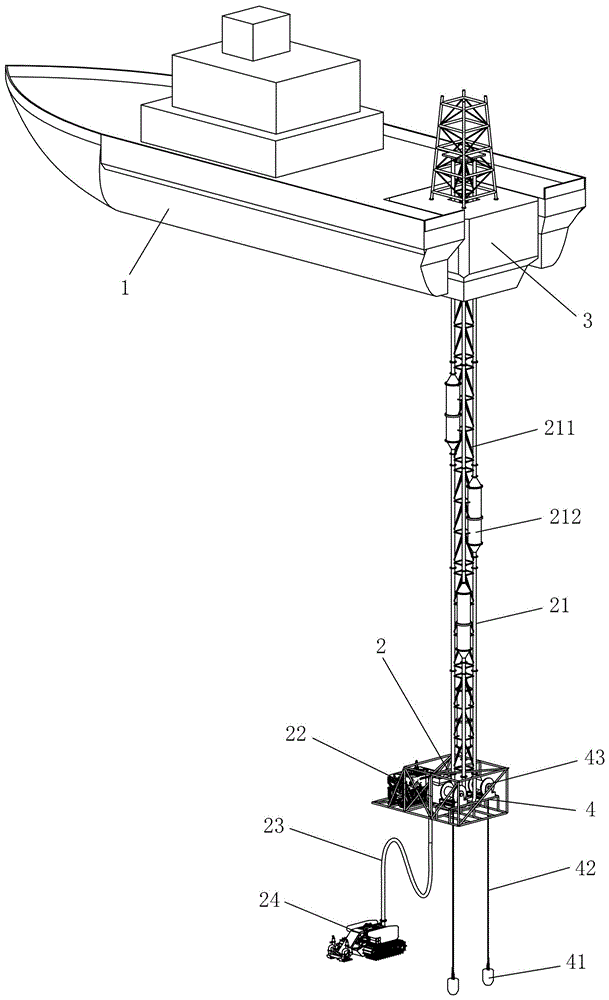

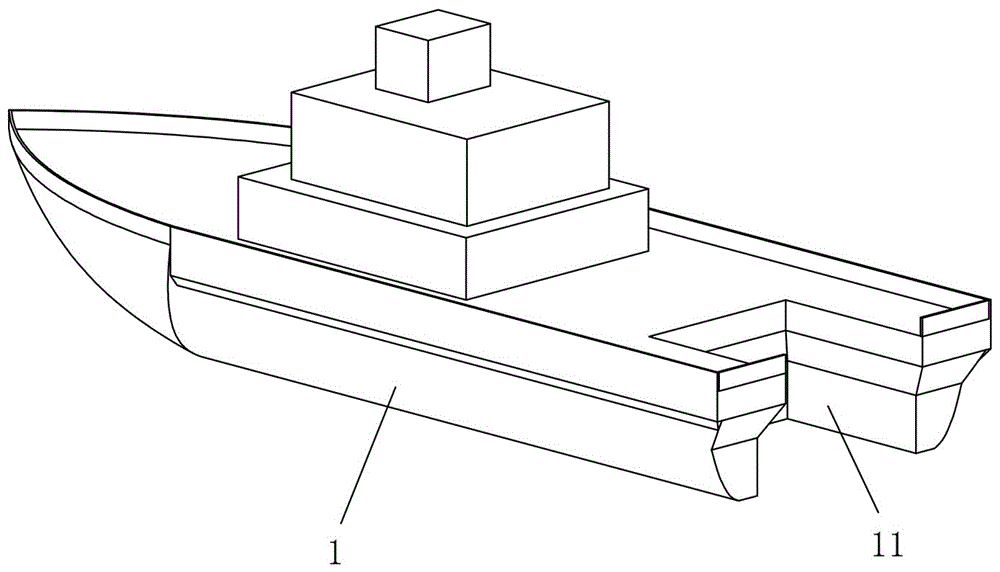

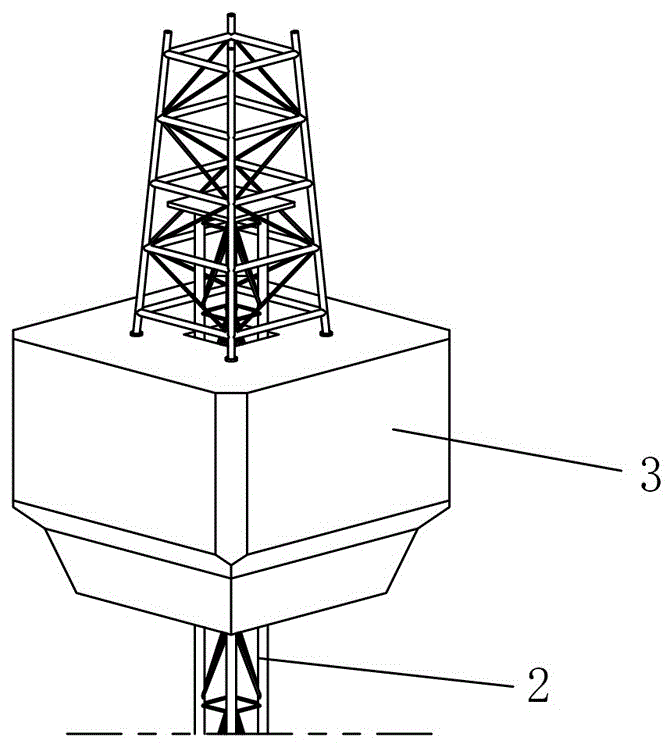

[0030] Such as Figure 1 to Figure 5 As shown, the deep-sea mineral resource mining system of this embodiment includes an operating mother ship 1, a mining system 2 and a floating platform 3, wherein the operating mother ship 1 and the mining system 2 are both existing technologies, and adopt the "mining system" recognized by the international deep-sea mining community. The basic structure of "ship-lifting system-mining machine", the floating platform 3 is detachably installed on the operating mother ship 1, the mining system 2 is connected with the floating platform 3, and the floating platform 3 can float on the water surface when the operating mother ship 1 is separated Above, the mining system 2 or the floating platform 3 is also connected with a dive control device 4, which can control the floating platform 3 to dive underwater o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com