Yarn sizing and shaping equipment for textile processing

An equipment and yarn technology, which is applied in the field of yarn sizing and setting equipment for textile processing, can solve the problems of easy deviation of the yarn position, inconvenience in winding and finishing, and a large number of components, and achieves convenient operation and setting operation. Simple and convenient, avoid the effect of position offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

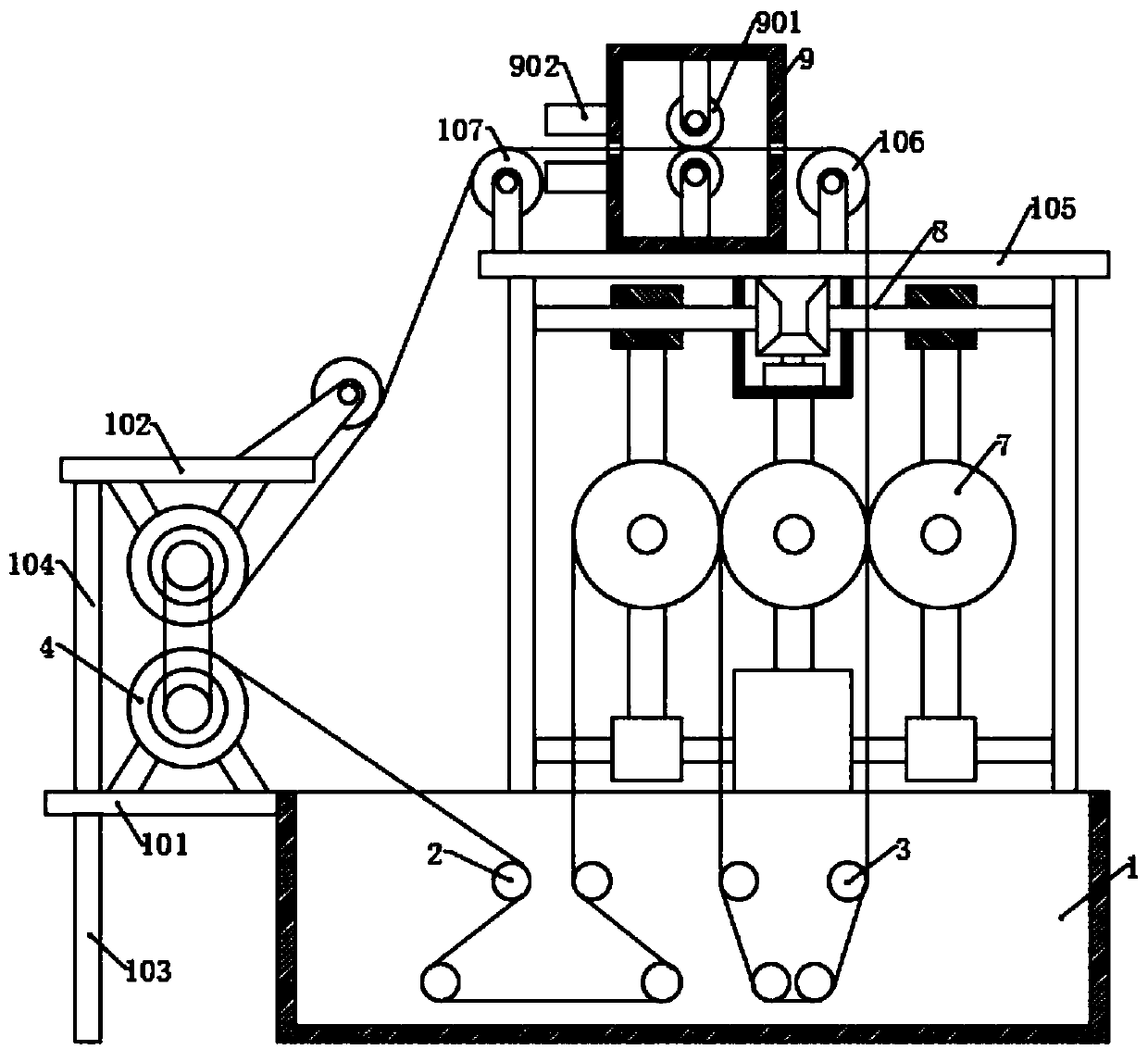

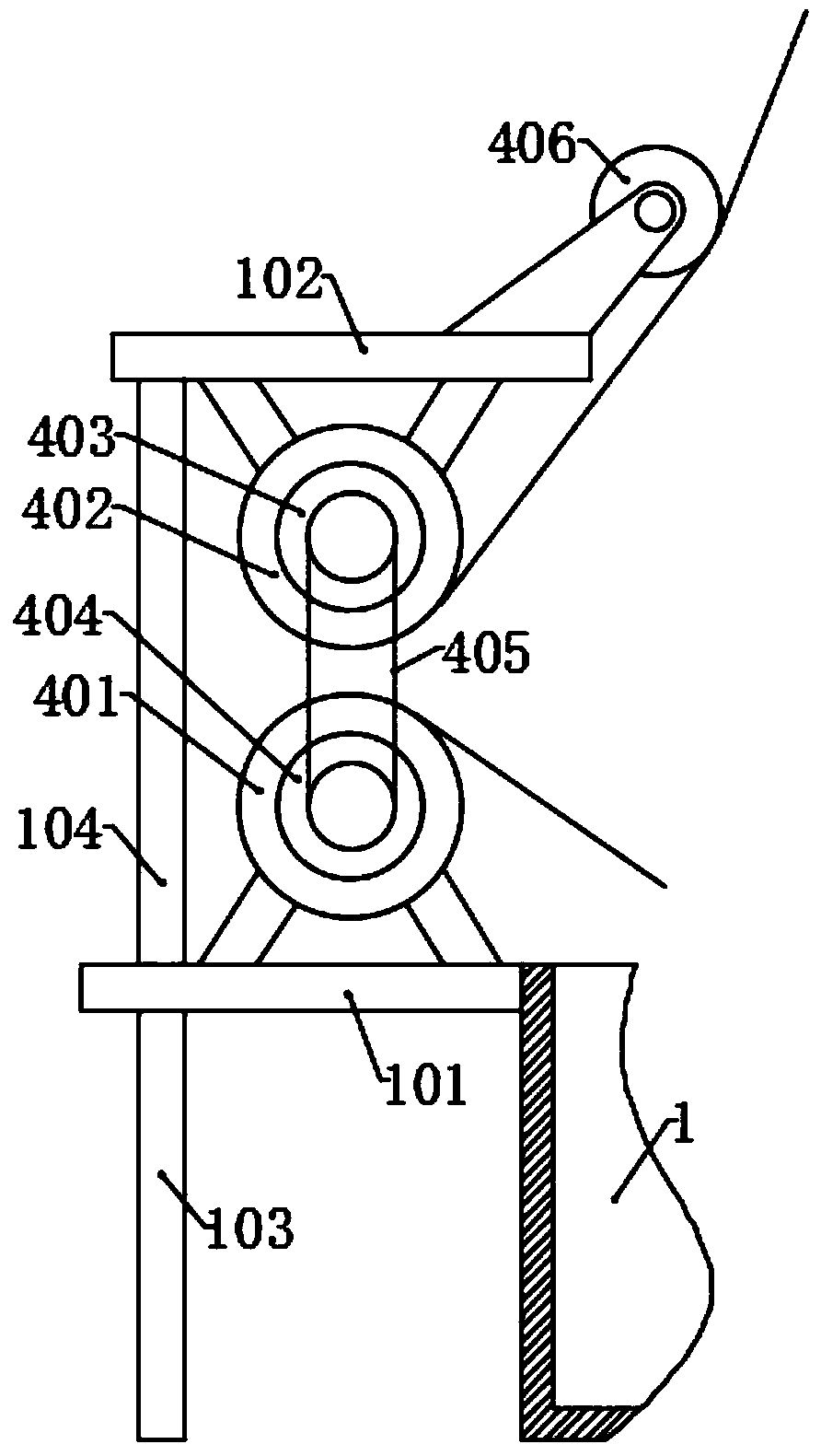

[0038] Please refer to the accompanying drawings, the present invention provides a technical solution: a yarn sizing and setting equipment for textile processing, including a sizing tank 1, a first sizing mechanism 2, a second admiral mechanism, a coiling mechanism 4, and an extrusion mechanism 7 And sizing box 9, the left side of described sizing tank 1 is fixed with lower fixed plate 101, and the bottom surface of lower fixed plate 101 is fixed with lower support bar 103, and top surface is fixed with upper support bar 104, and is fixed with upper support bar 104 The upper fixed plate 102, the coiling mechanism 4 is arranged between the upper support plate and the lower support plate, the first sizing mechanism 2 and the second sizing mechanism 3 are arranged in the sizing tank 1, the two sizing tanks 1 A fixed frame is fixed laterally symmetrically, and a top plate 105 is fixed on the top surface of the fixed frame. The extruding mechanism 7 is arranged between the two fixed...

Embodiment 2

[0046] On the basis of Embodiment 1, an adjustment mechanism 8 is also included, and the top and top of the fixed frame are provided with an adjustment mechanism 8. The adjustment mechanism 8 includes a motor box, and an adjustment motor 808 is arranged in the motor box. The motor 808 is connected with a driving bevel gear 807, and the two sides of the driving bevel gear 807 are respectively symmetrically meshed with a first bevel gear 803 and a second bevel gear 806, and the first bevel gear 803 is fixedly connected with the first screw rod 801, the first The screw rod 801 is sleeved with a first moving block 802, and the two first moving blocks 802 located at the upper and lower parts of each fixed frame are respectively fixedly connected with the upper and lower ends of the connecting rod 710 of the first pressure roller 701, so that The second bevel gear 806 is fixedly connected to the second screw rod 804, the second screw rod 804 is sleeved with a second moving block 805,...

Embodiment 3

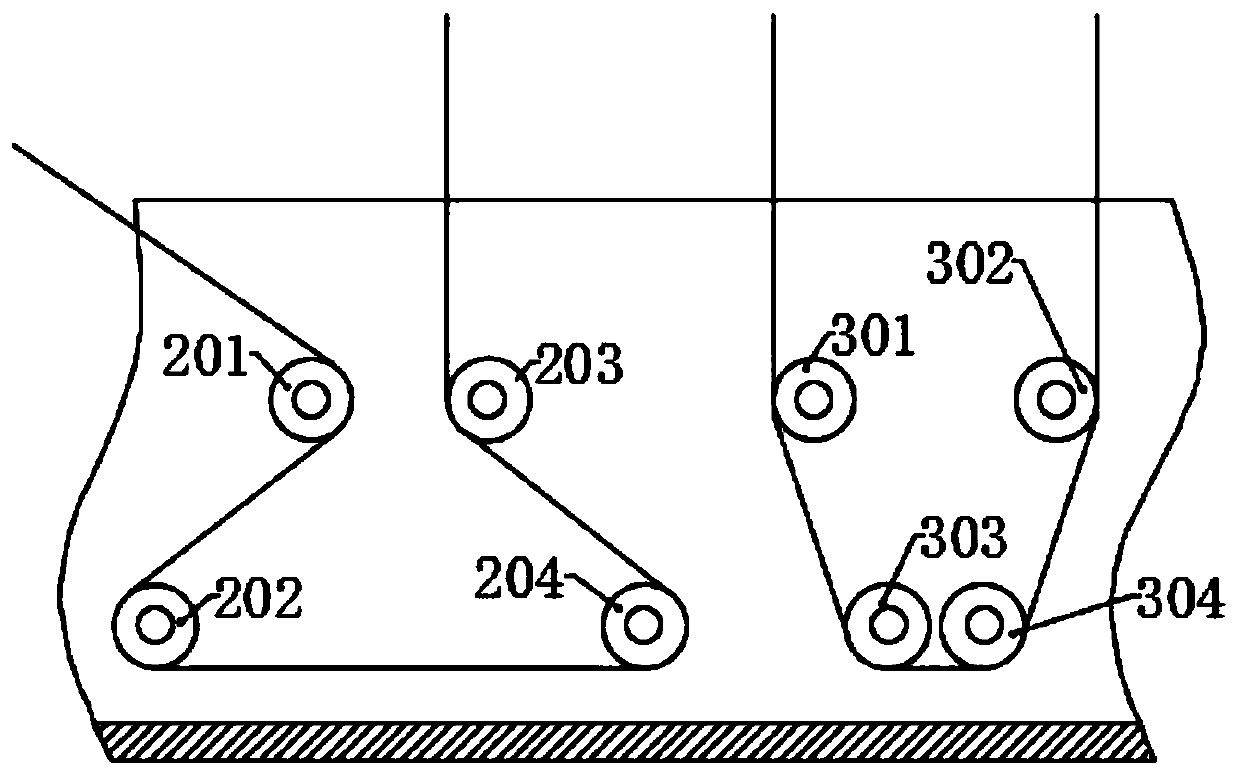

[0049] On the basis of the second embodiment, it also includes a first transmission mechanism 5 and a second transmission mechanism 6, the first transmission mechanism 5 and the second transmission mechanism 6 are arranged on the outer wall of the sizing tank 1, and the first transmission mechanism Mechanism 5 includes four first belt pulleys 501, and is respectively fixedly connected with the first sizing roller 201, the second sizing roller 202, the third sizing roller 203 and the fourth sizing roller 204, and the first belt pulley 501 is also provided with There is a first transmission belt 503, and a first adjustment wheel 502 is provided on the outer wall of the sizing tank 1, and the first adjustment wheel 502 is correspondingly connected with the first transmission belt 503. The second transmission mechanism 6 includes four second The pulley 601 is fixedly connected with the second sizing roller 202, the second sizing roller 202, the third sizing roller 203 and the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com