Warp beam cage with baking function and method for baking warp beam yarns or fabrics

A baking method and beam yarn technology, which is applied in the field of warp beam dyeing, can solve the problems of high liquid rate, waste, and unsatisfactory problems such as warp beam yarn or fabric, and achieve the effects of facilitating industrial application, reducing production costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The water-repellent finishing agent is TG-5263, purchased from Daikin Fluorochemical (China) Co., Ltd.

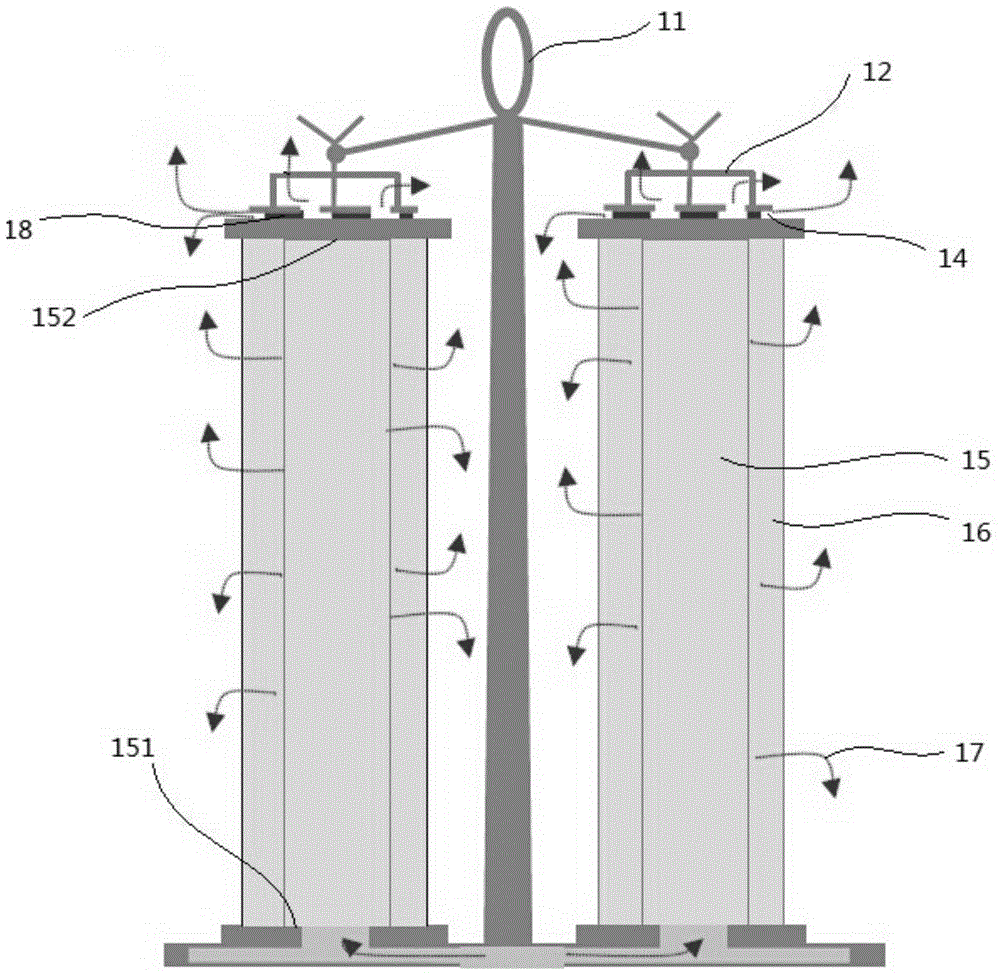

[0034] The bakeable beam cage of the present invention is as figure 1 As shown, it includes a shaft frame 11, a shaft body 15 and an air release device, and the shaft body 15 is installed on the shaft frame 11 through the first connecting portion 151;

[0035] The air release device includes a cover plate 12, a second connection portion 152 and a plurality of air release ports, the shaft body 15 is installed on the cover plate 12 through the second connection portion 152, and the air release port communicates with the shaft The inner and outer channels of the body 15.

[0036] During the baking process, high-temperature and high-pressure air enters the inner side of the shaft body 15 through the shaft frame 11, causing a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com