Air-conditioner heat dissipation copper pipe drawing-inserting mechanism

A technology for heat-dissipating copper tubes and copper tubes, applied in heat exchange equipment, feeding devices, positioning devices, etc., can solve the problems of easy bending of heat-dissipating copper tubes, damage to heat-dissipating copper tubes, low efficiency, etc., to reduce labor intensity and improve efficiency. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

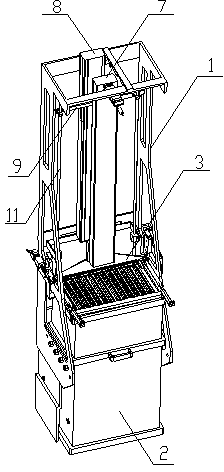

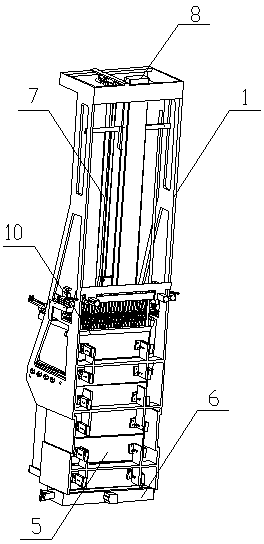

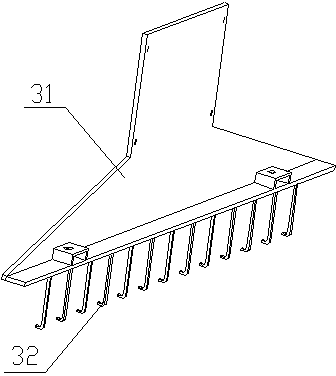

[0028] Example: see Figure 1 to Figure 6 , an air conditioner radiating copper pipe pulling and inserting mechanism, comprising a rack 1, a material box 2, a hook mechanism 3, a radiating copper pipe clamping mechanism, a guiding mechanism 5 and a radiating copper pipe port correction mechanism 6, the rack includes a horizontal setting The material box carrier plate and the side plates vertically arranged on the left and right sides of the material box carrier plate, the material box carrier plate is connected with the lower part of the two side plates, and the upper ends of the two side plates are connected by the front and rear connecting plates, so that the frame The upper end is in a rectangular frame structure.

[0029] The material box is installed on the material box carrier plate and is detachably connected with the two side plates; the material box is a box structure with an upper opening, and the height of the rear side plate is lower than the height of the other thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com