Patents

Literature

32results about How to "Avoid mesh clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

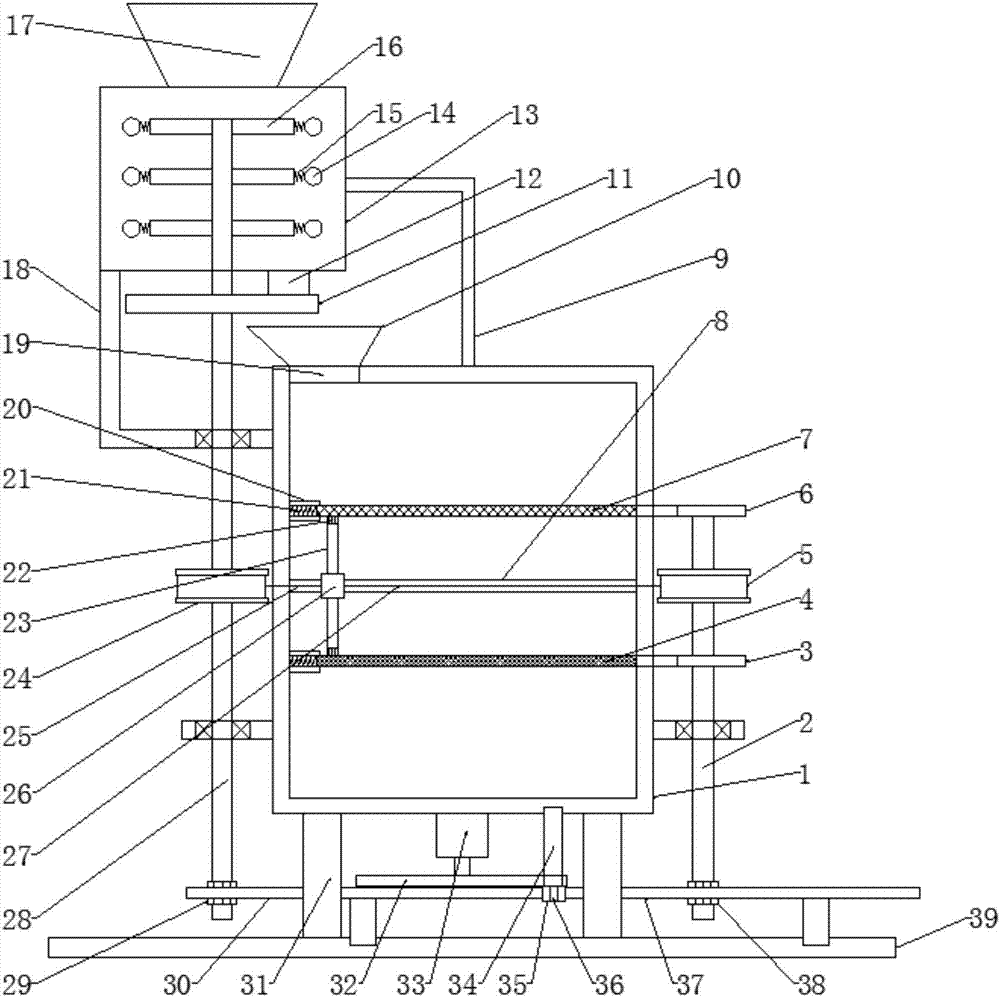

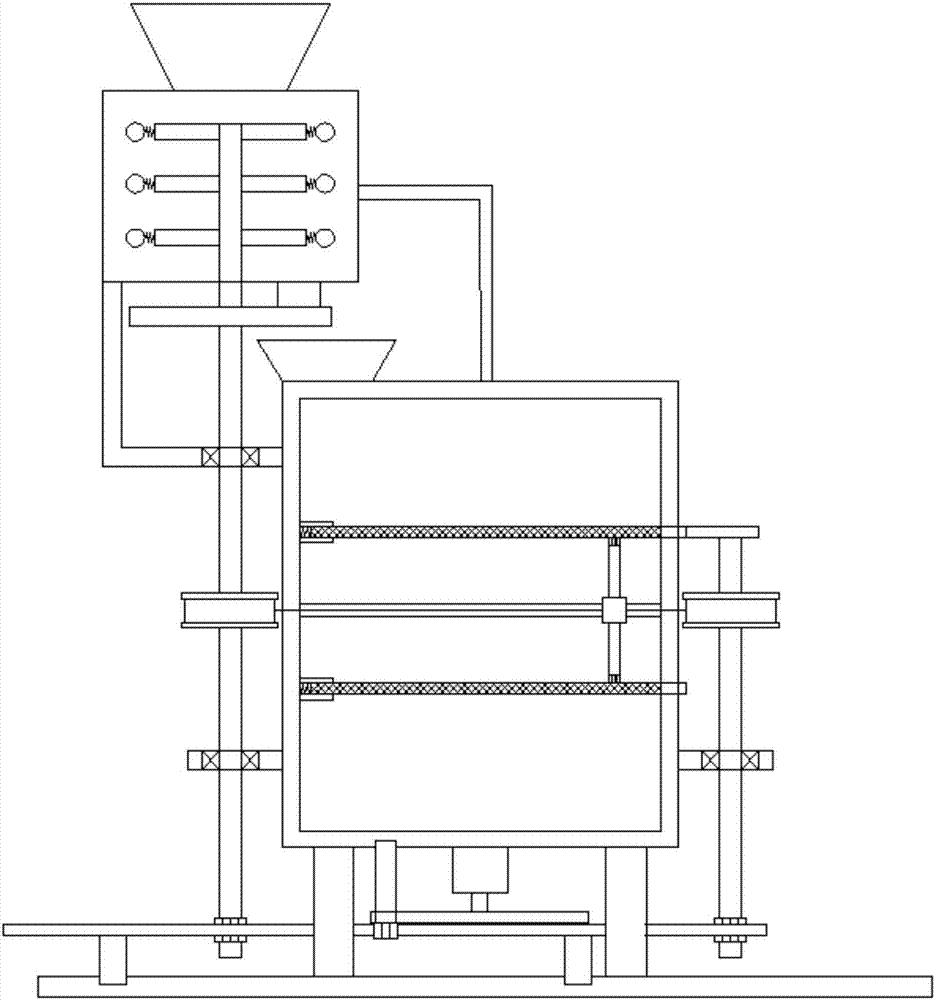

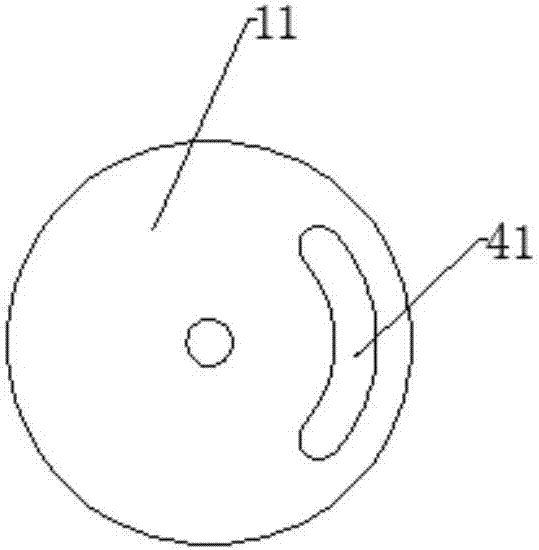

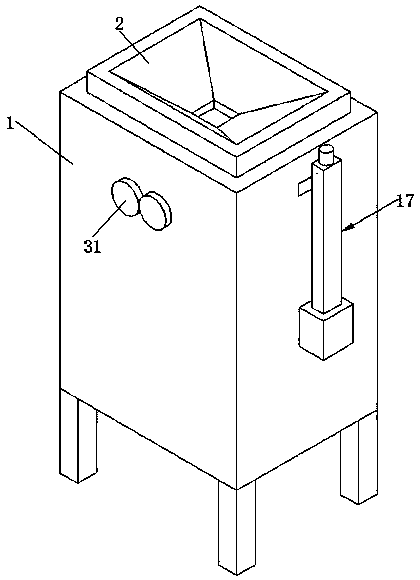

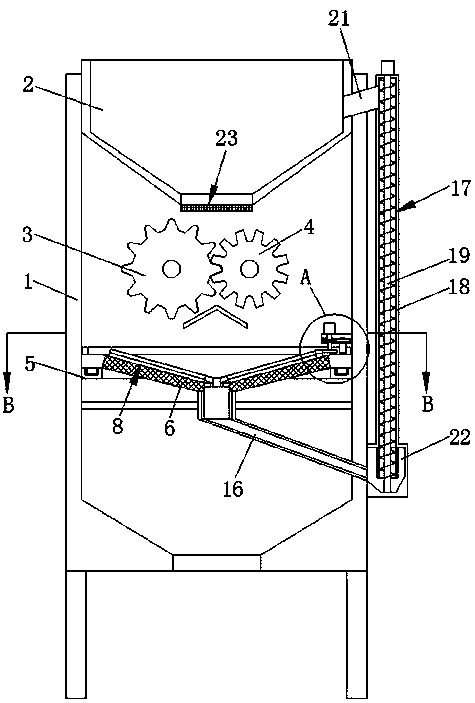

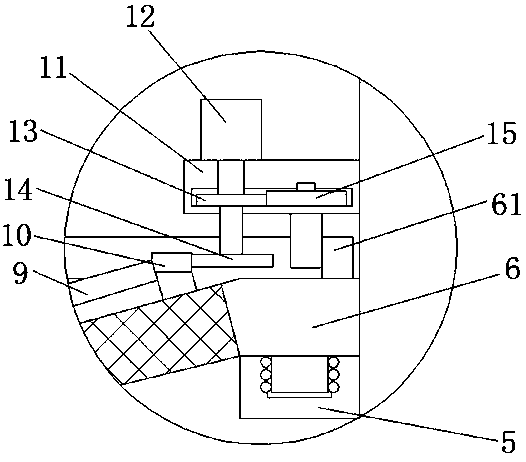

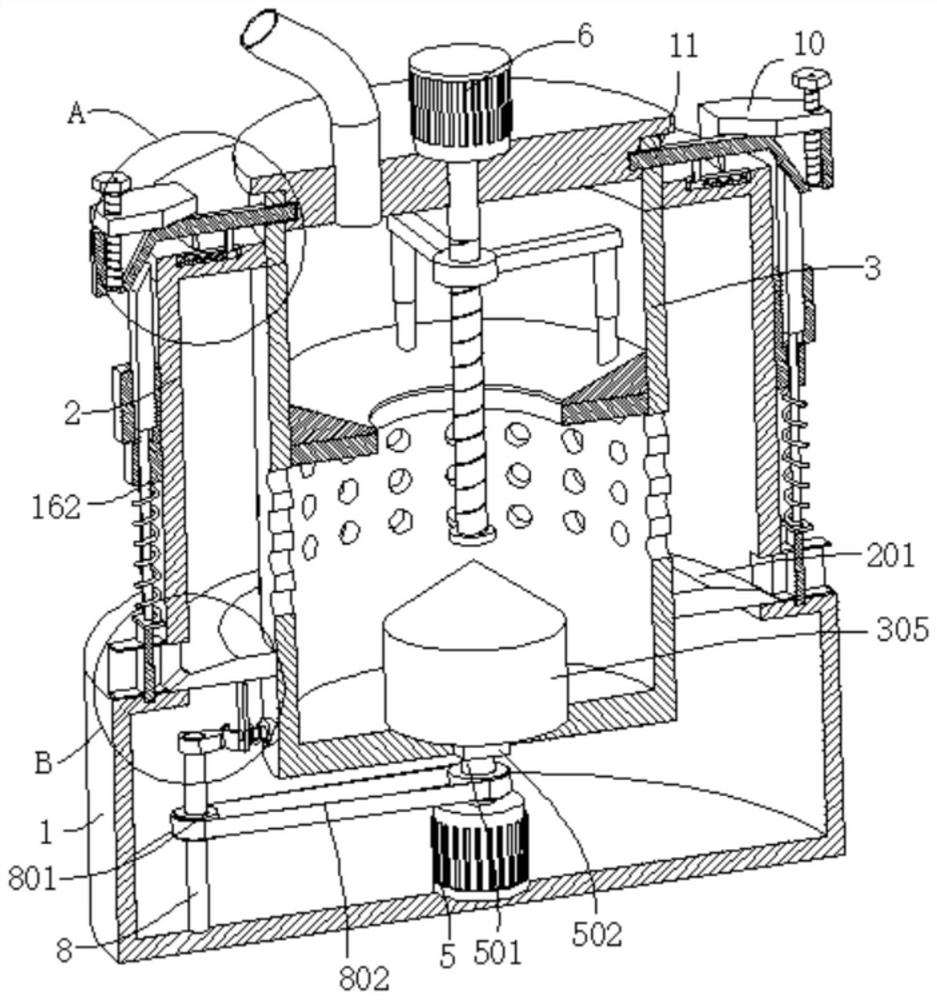

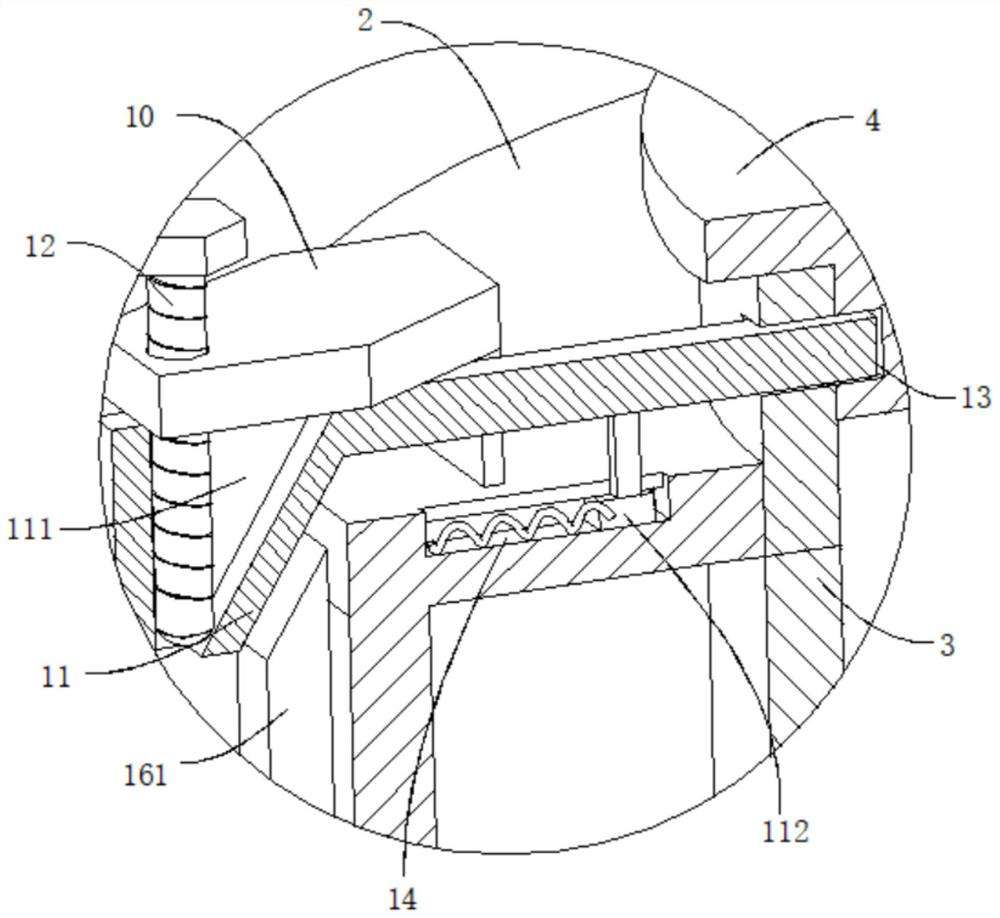

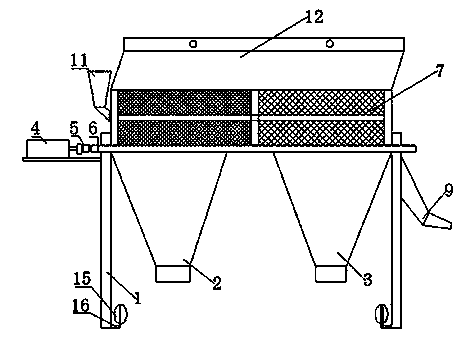

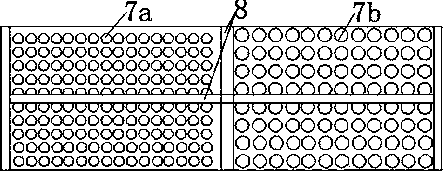

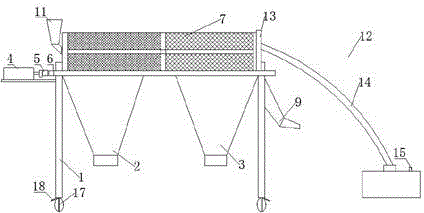

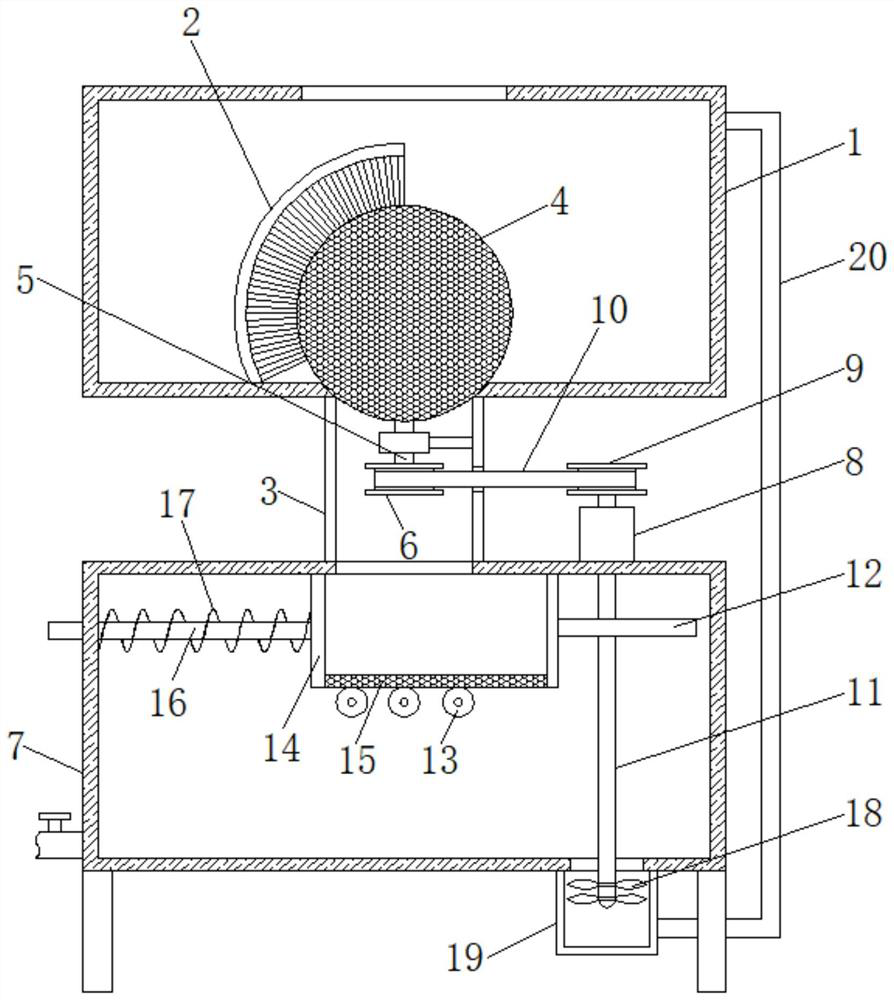

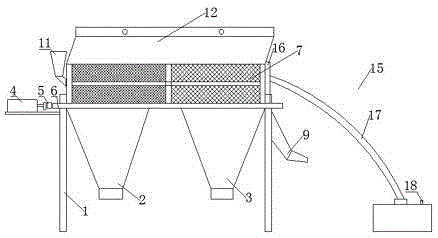

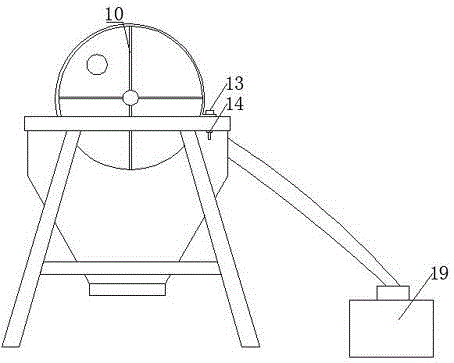

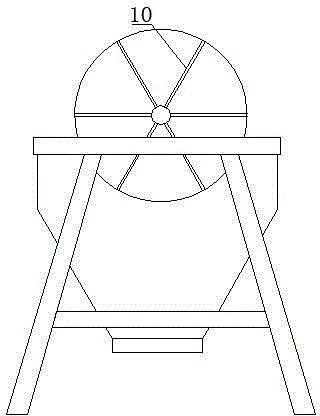

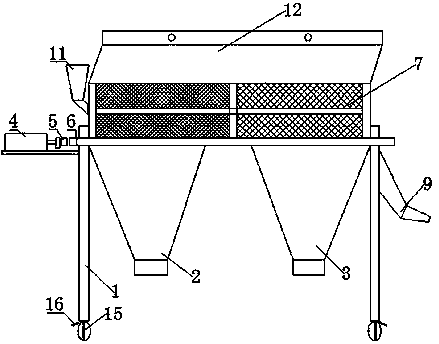

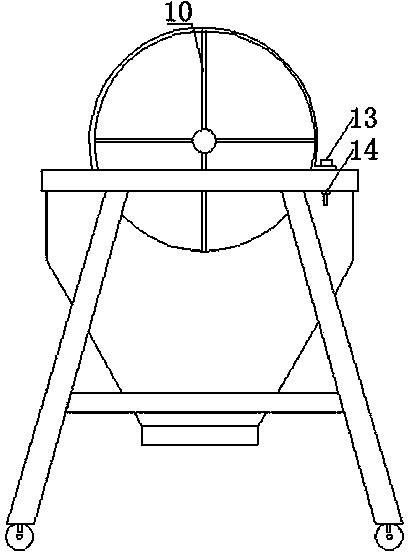

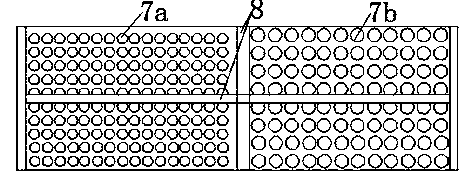

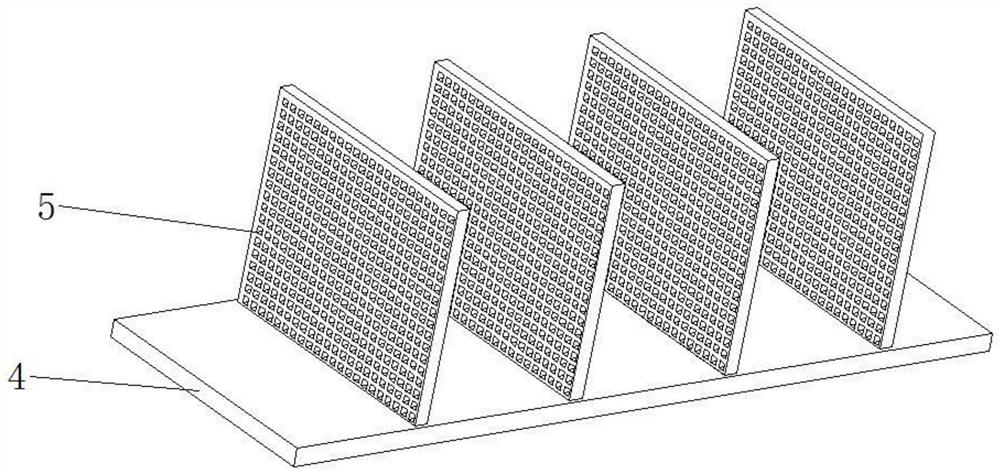

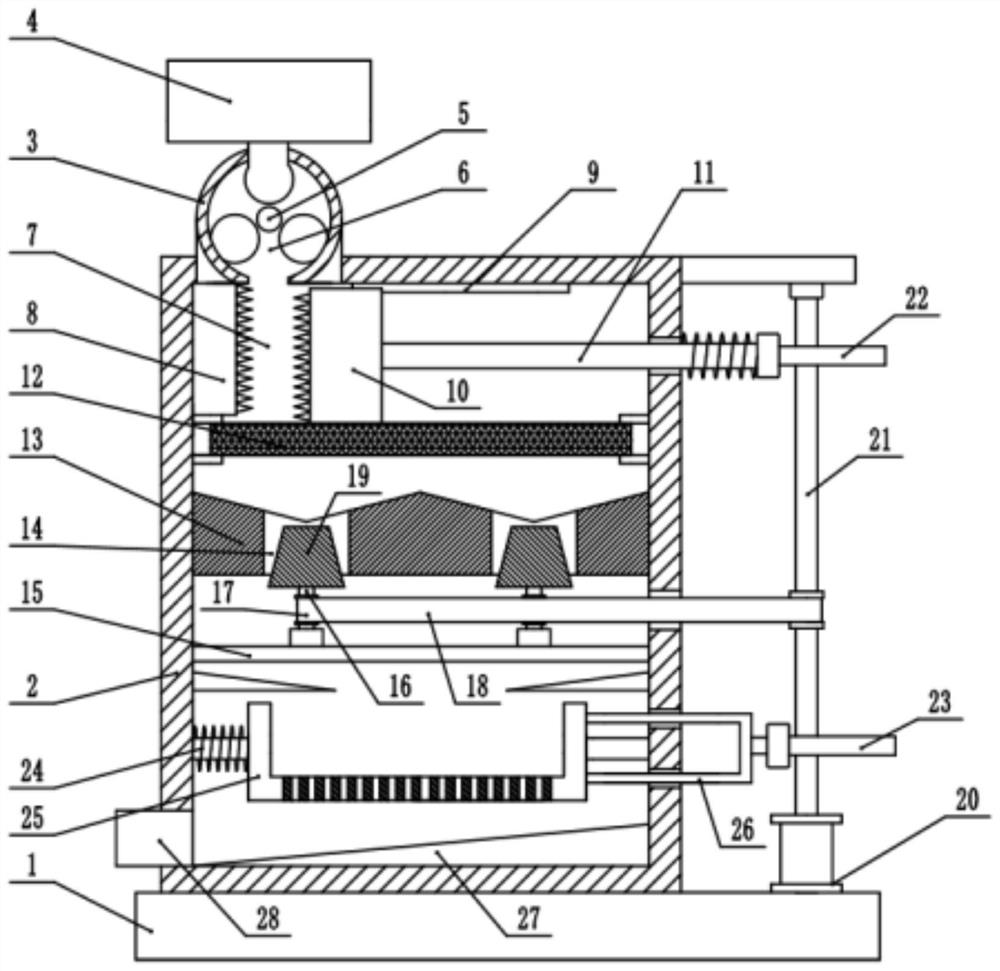

Multistage efficient sand screening device for constructional engineering

InactiveCN107442216AAvoid mesh cloggingImprove screening efficiencySievingScreeningCamConductor Coil

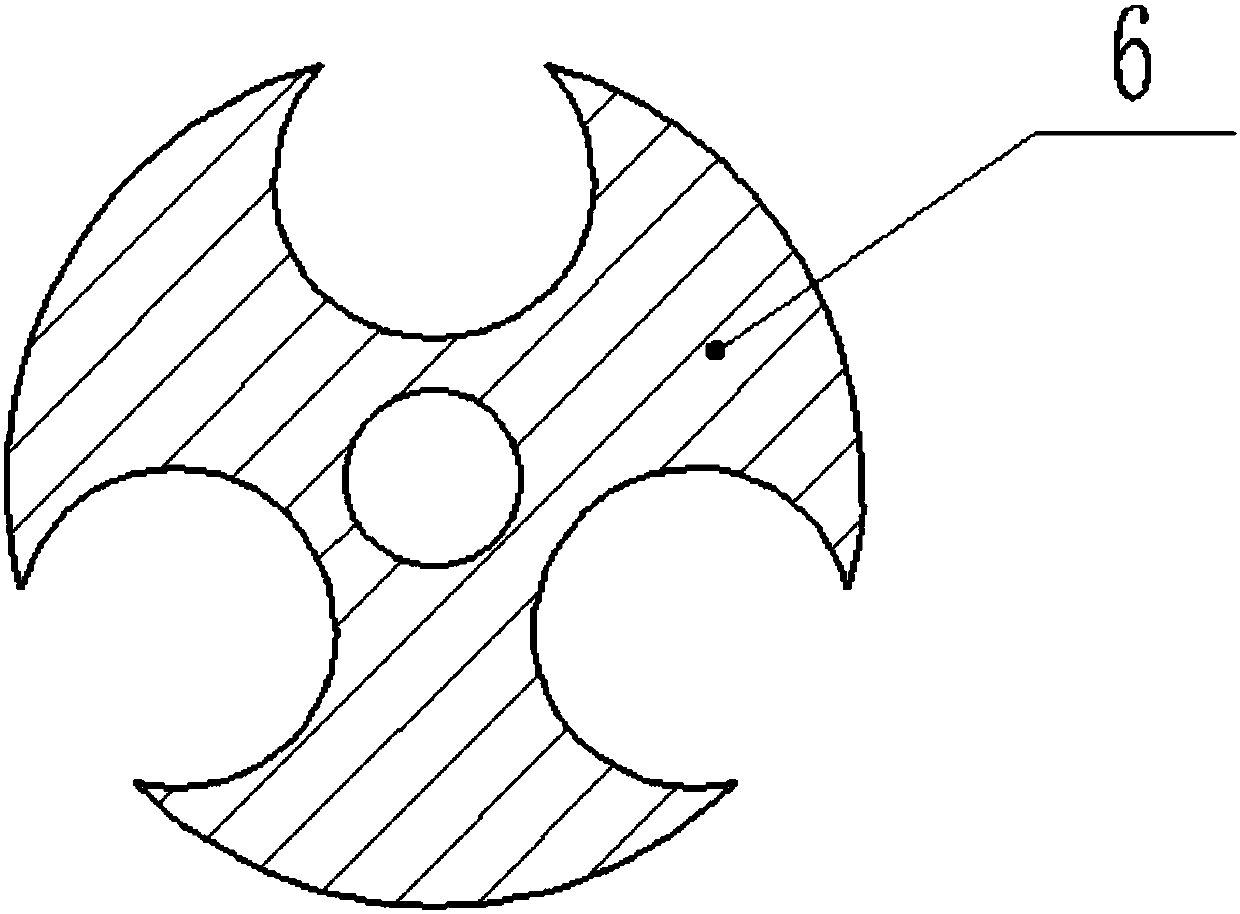

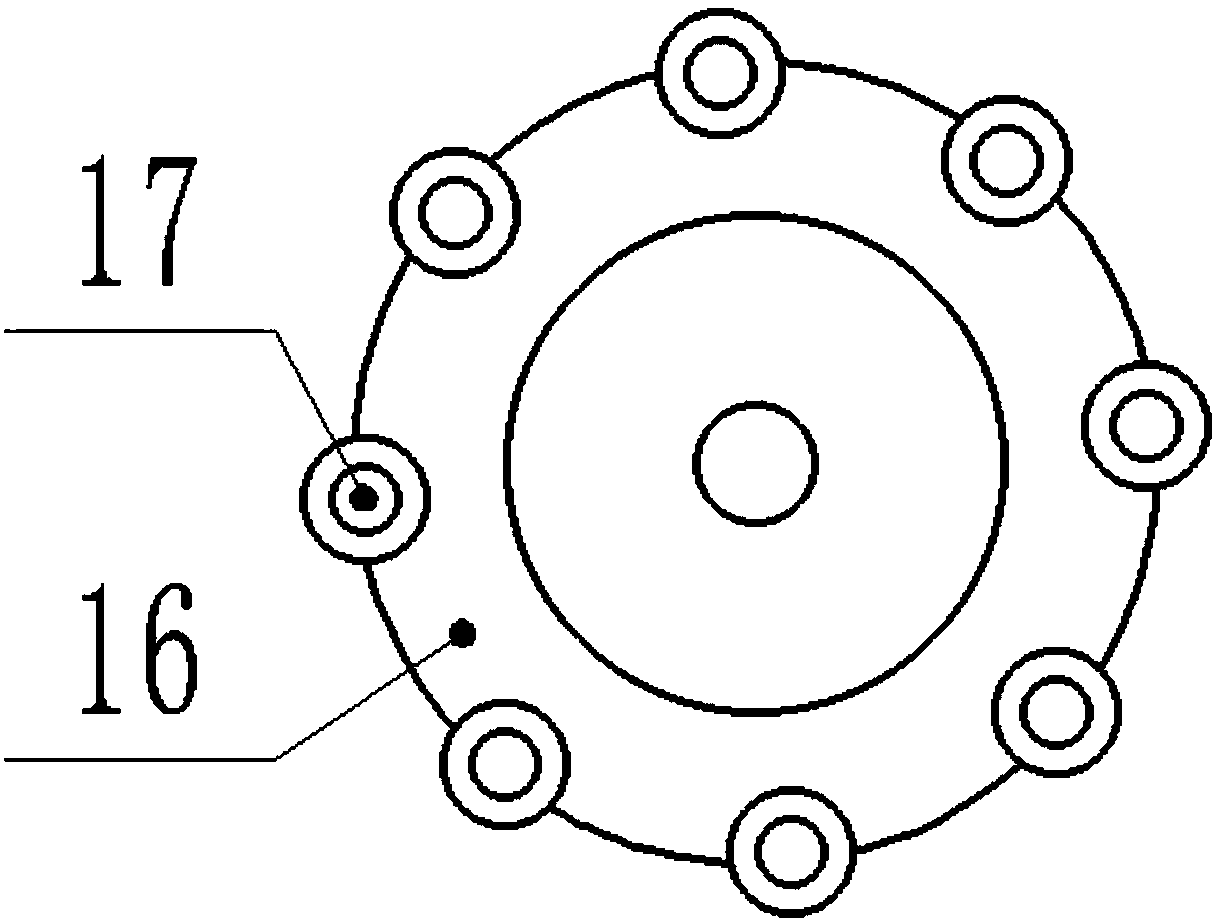

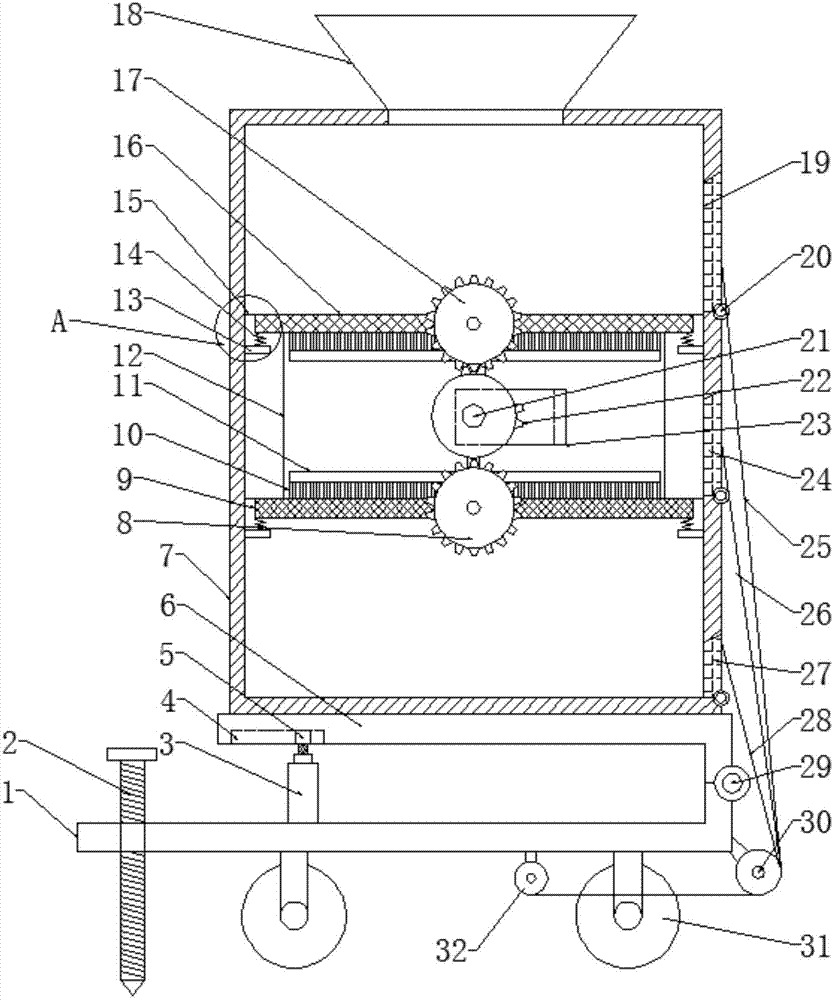

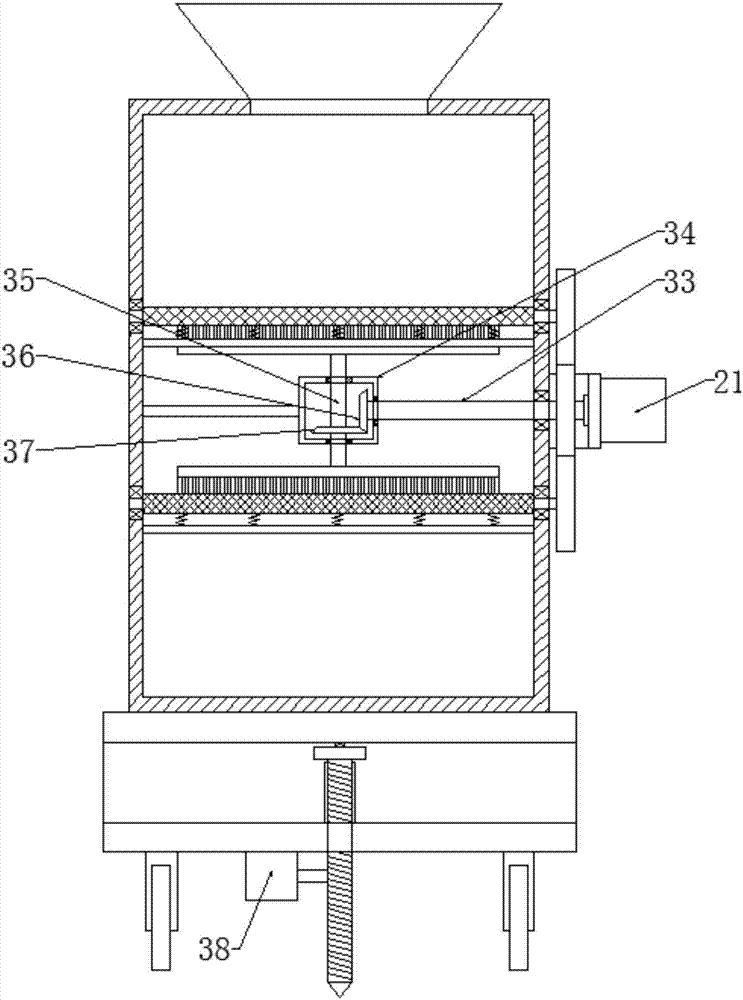

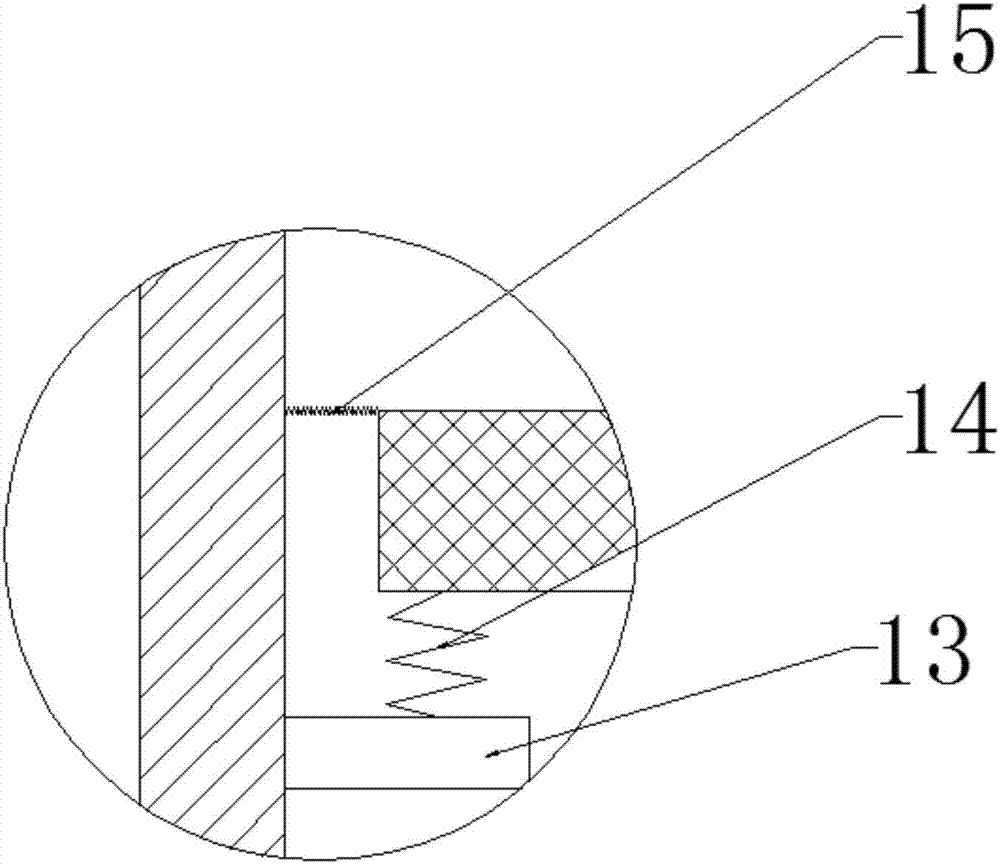

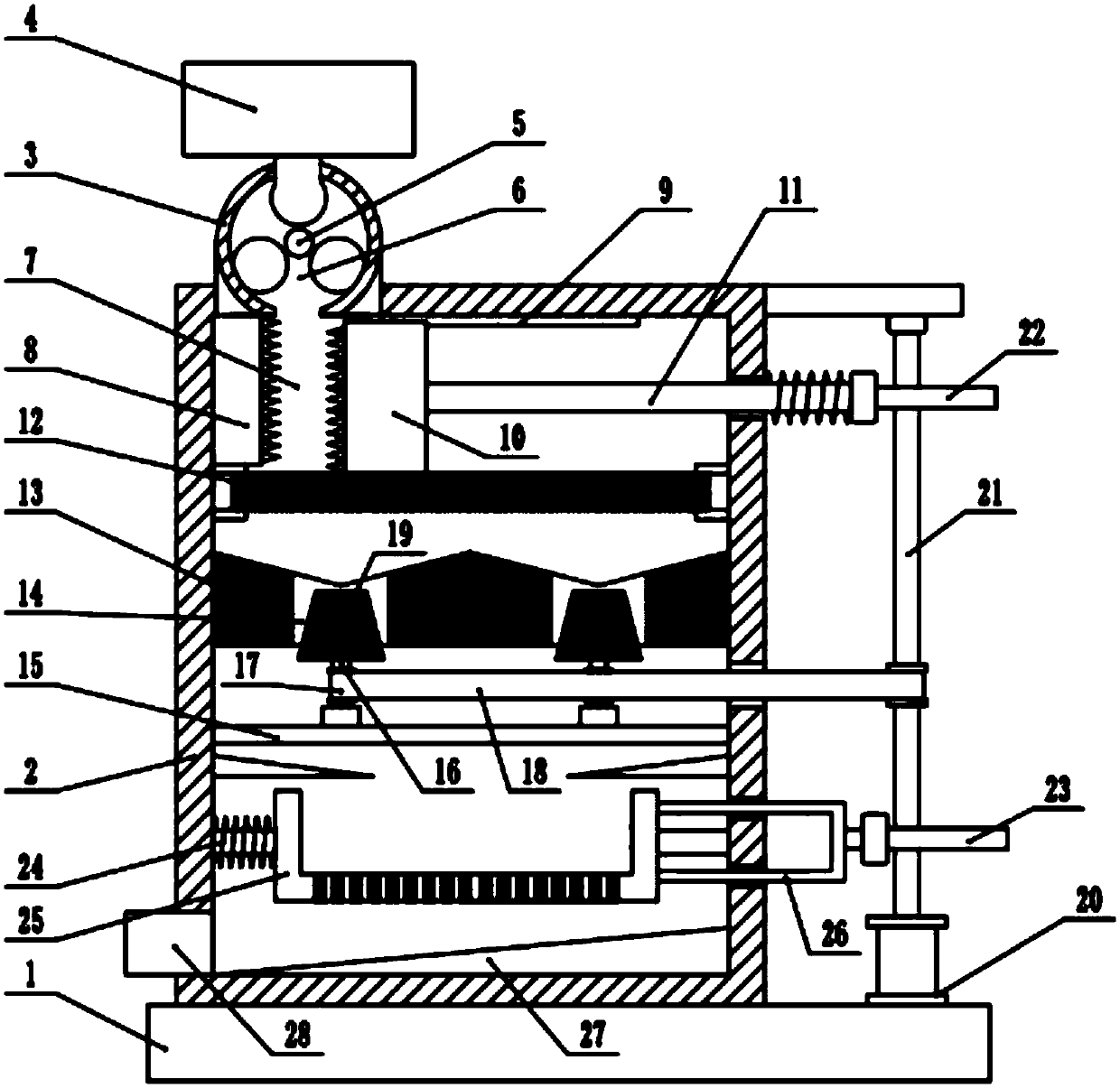

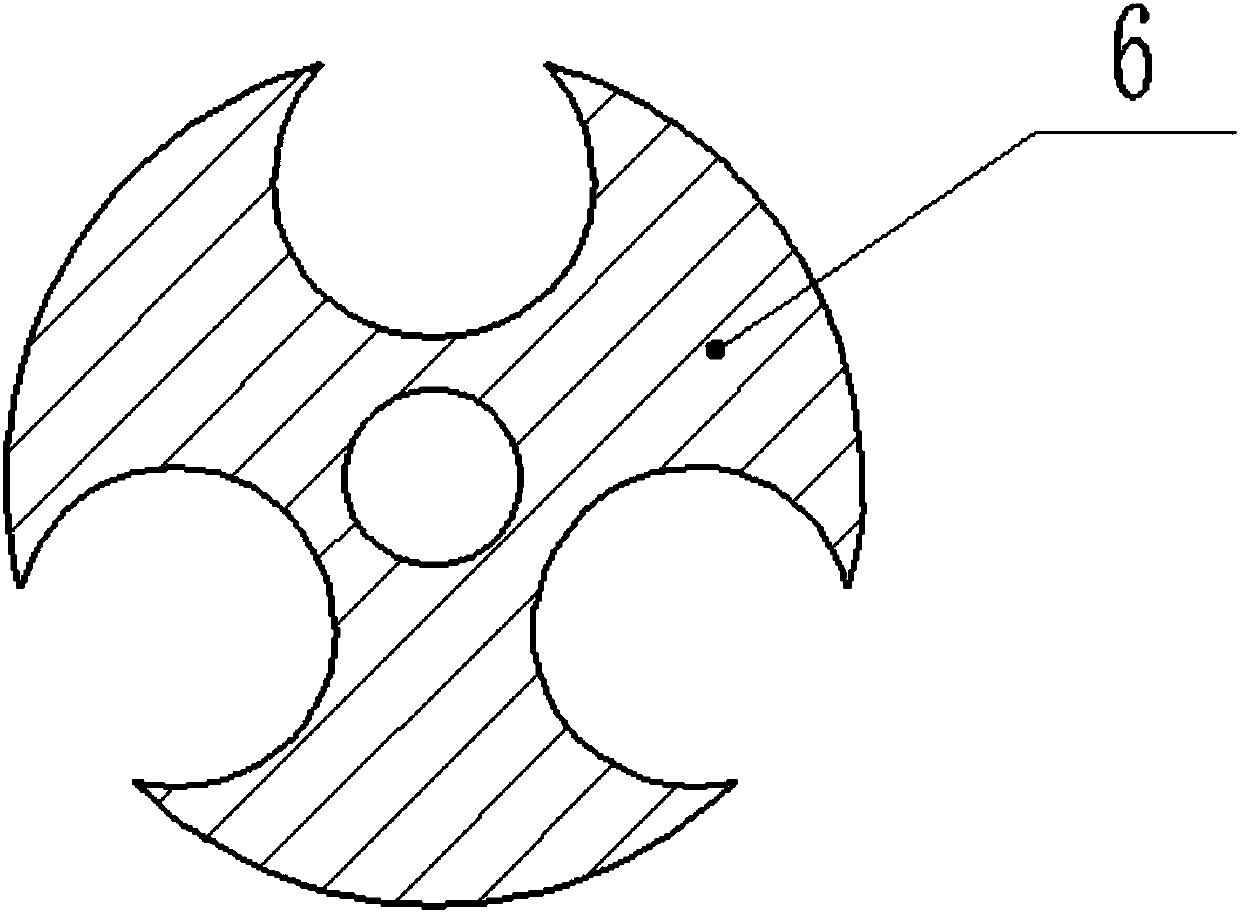

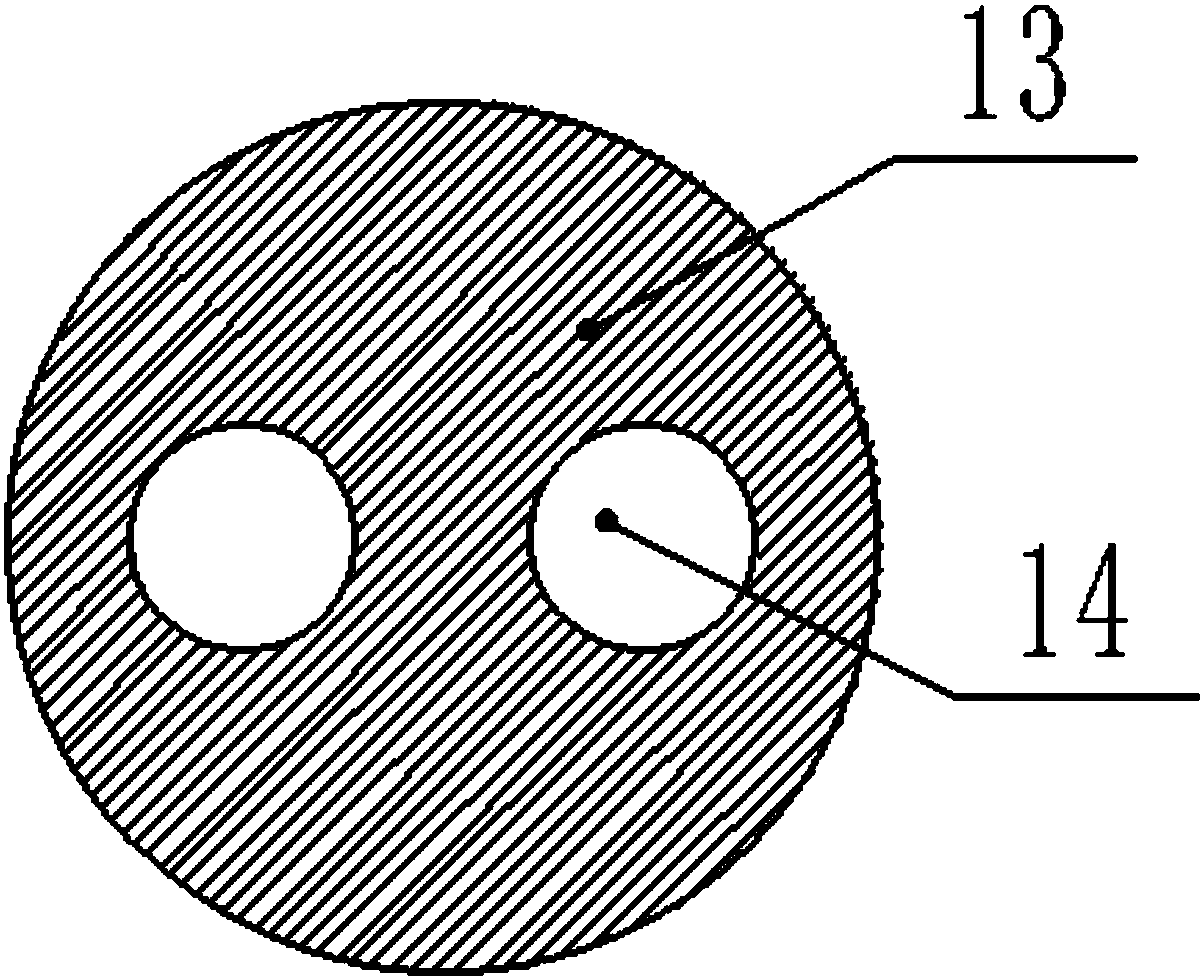

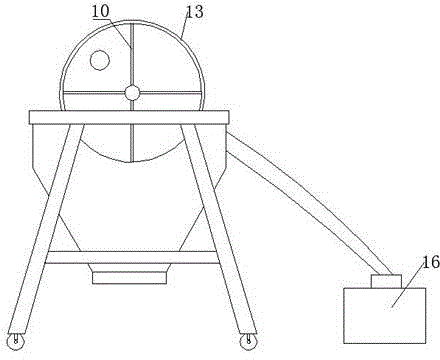

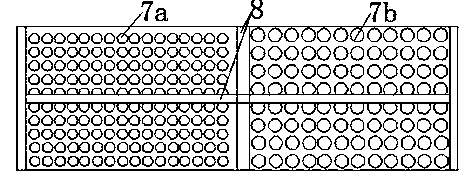

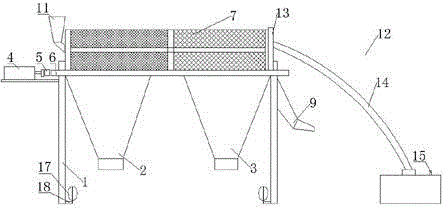

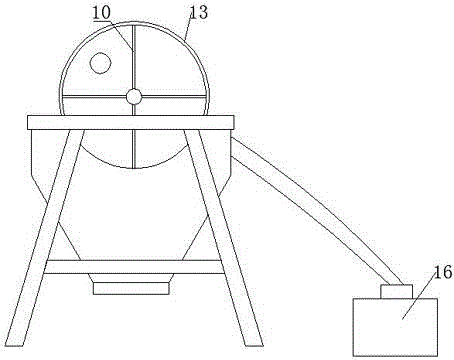

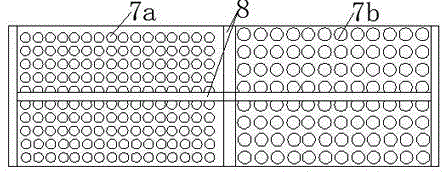

The invention discloses a multi-stage high-efficiency sand screening device for construction engineering, which comprises a base plate, a sand screening box, a crushing device, a first screen, a second screen, a second spring, a sliding rod, a sliding sleeve, a connecting plate, a wool Brush, transmission mechanism, first gear, first reel, first traction rope, second gear, first cam, second cam, second reel and second traction rope, said transmission mechanism includes motor, The second disc, the movable rod, the first rack and the second rack, the present invention is provided with a crushing device, which crushes the agglomerated sand, avoids affecting the efficiency of sand screening, and is provided with a transmission mechanism, a first winding wheel, The second winding wheel, sliding rod, sliding sleeve, connecting plate and brush drive the brush to move left and right, brush the first screen and the second screen, and avoid the mesh holes of the first screen and the second screen from being blocked , Improve the screening efficiency, equipped with a first cam, a second cam and a second spring, so that the first screen and the second screen shake left and right, further improving the screening efficiency.

Owner:李大川

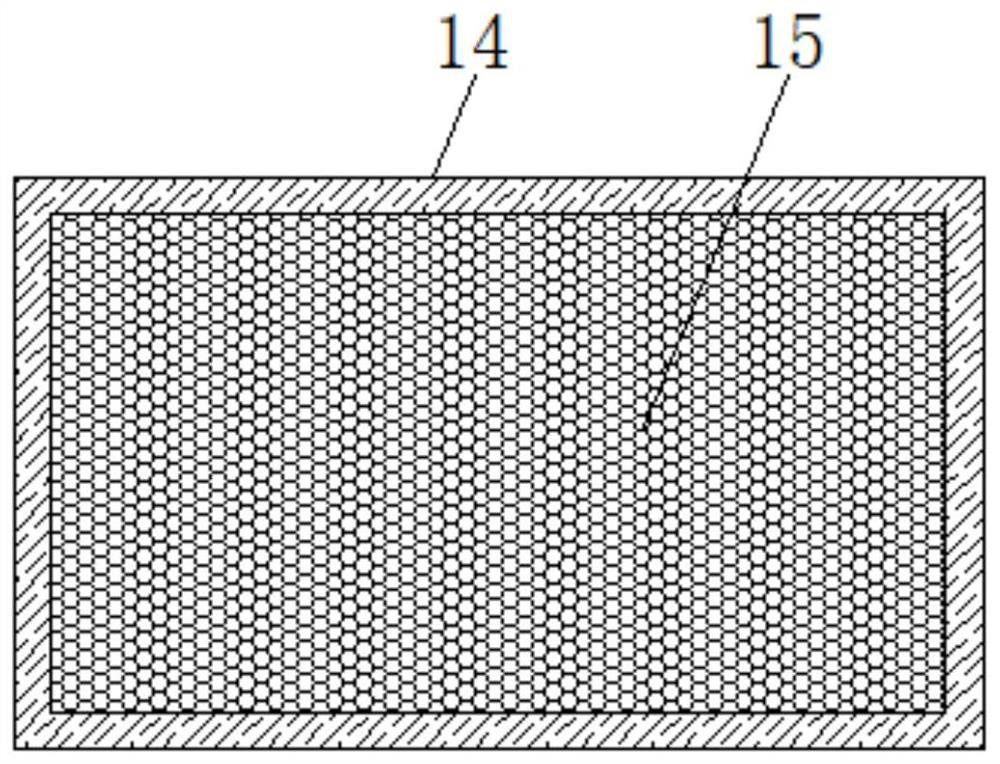

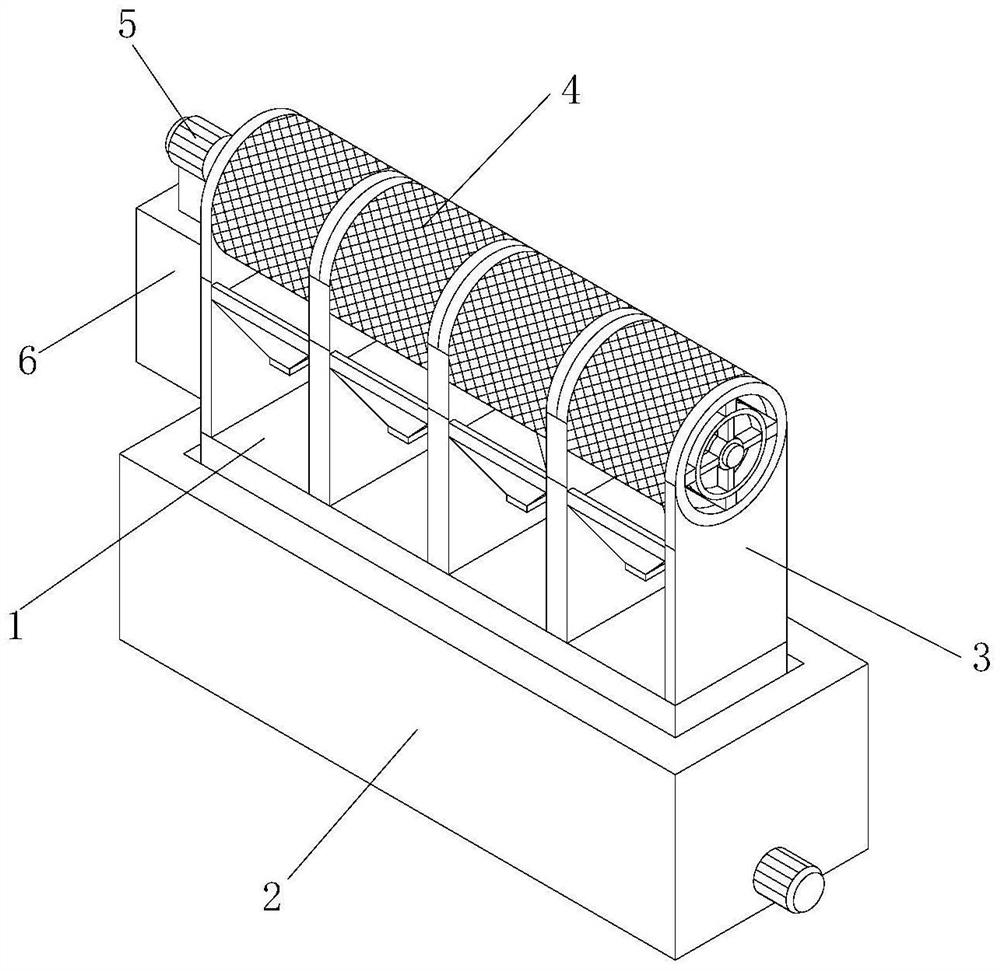

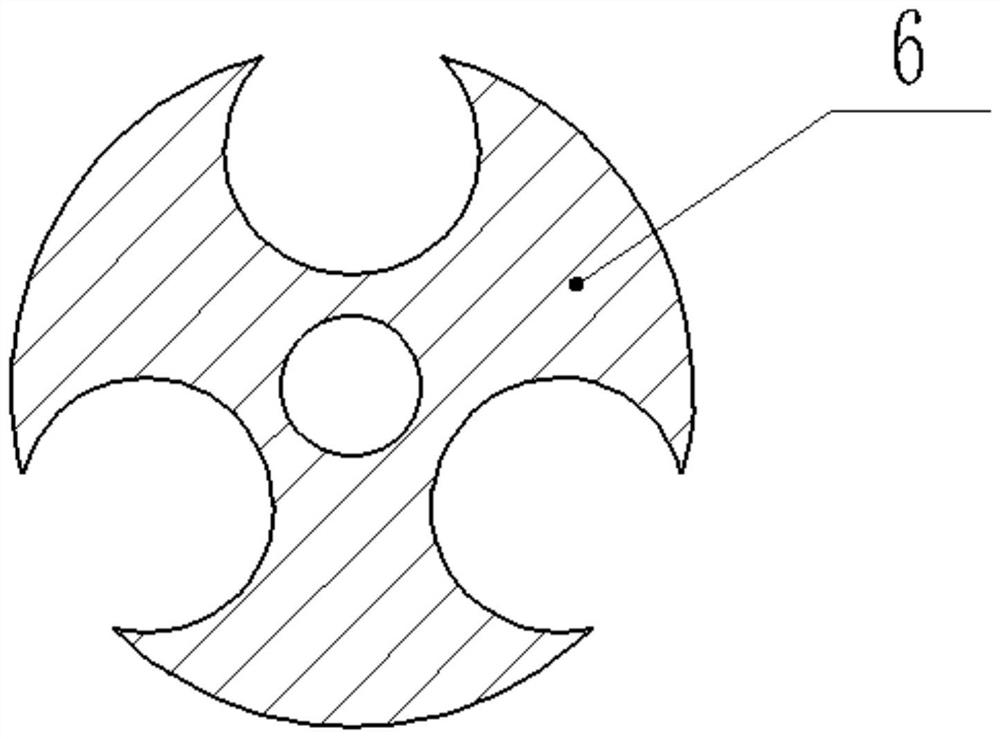

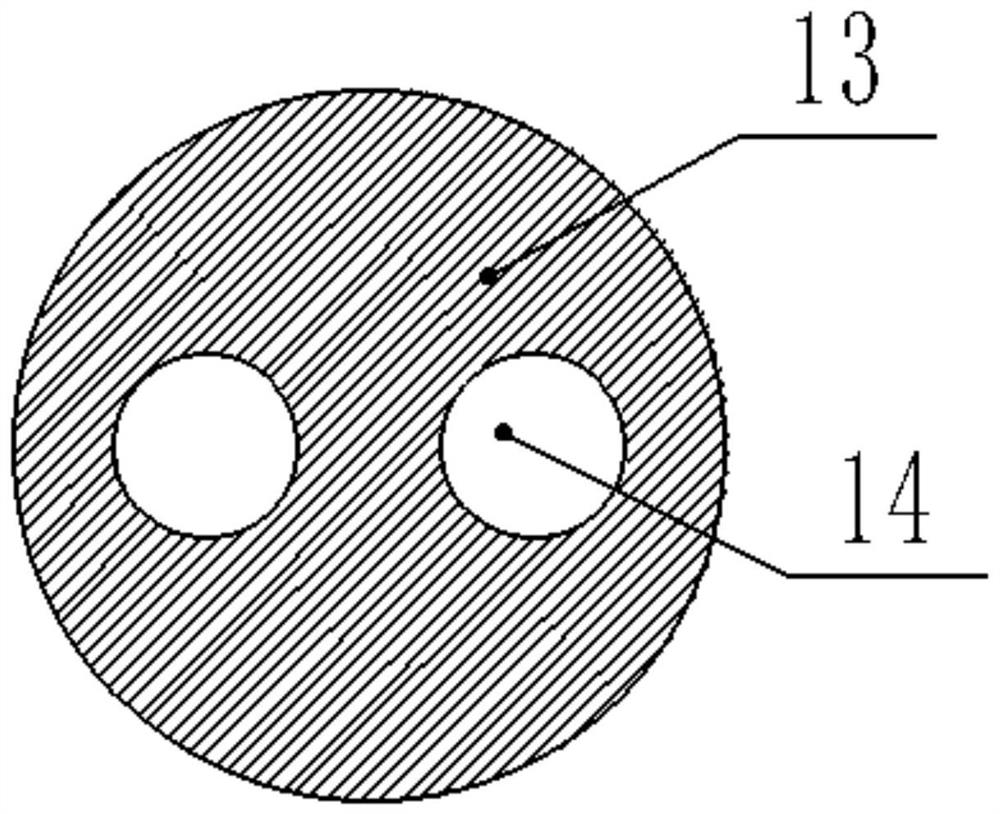

Energy-saving type roller type fine grinding device for PVC new material machining

InactiveCN110152766AImprove crushing effectAvoid situations where crushing is not in placeSievingScreeningElectric machineDrive motor

The invention discloses an energy-saving type roller type fine grinding device for PVC new material machining. The device comprises a base, a grinding box, a dividing device, a driving motor, and a screening groove; the dividing device is arranged on the left side of the top of the grinding box, a primary grinding cavity is formed in the upper portion in the grinding box, a limiting sliding rod ishorizontally welded into the grinding box, the screening groove is arranged on the limiting sliding rod in a sliding manner, a PVC new material is subjected to intervalic charging, through PVC new material grinding, the blockage appearing in smashing due to too much one-time charging is avoided, the grinding effect is greatly improved, during screening, the screening groove moves left and right,screening speed of the PVC new material powder in the screening groove is improved, the condition that the PVC new material powder blocks meshes is avoided, meanwhile, through the driving motor, grinding and screening are driven at the same time, the use rate of the motor is greatly saved, meanwhile, the energy saving effect is achieved, and the device is energy-saving and environment-friendly.

Owner:沛县豪岳新材料技术服务中心

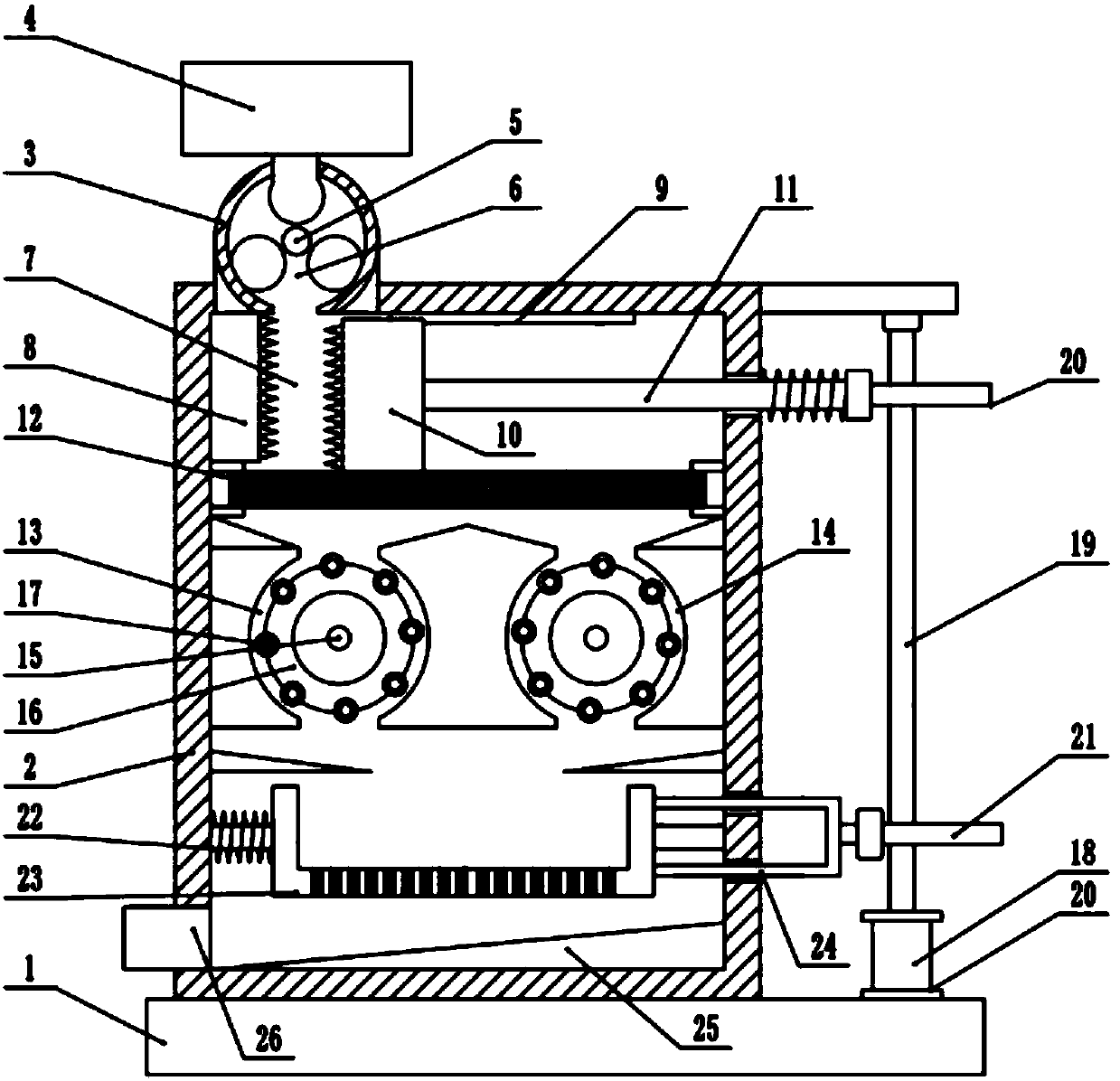

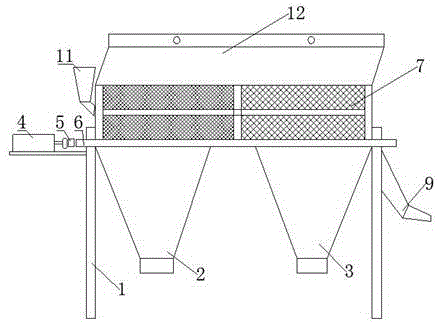

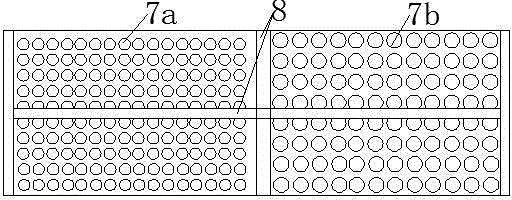

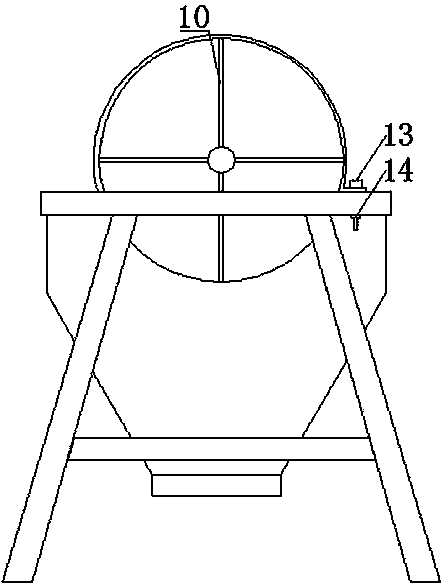

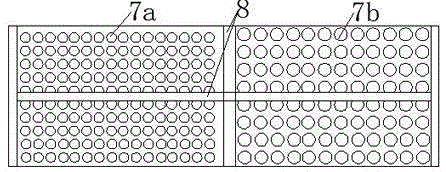

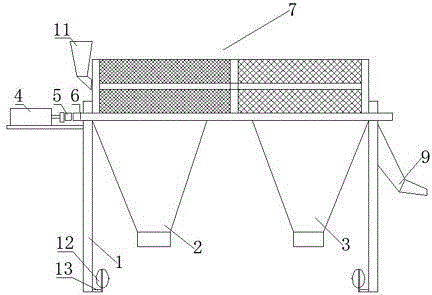

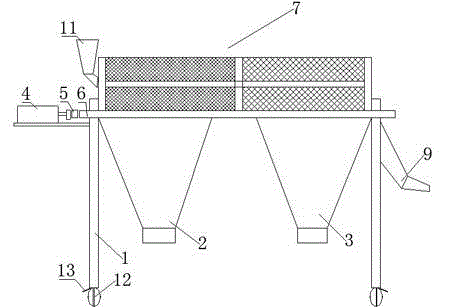

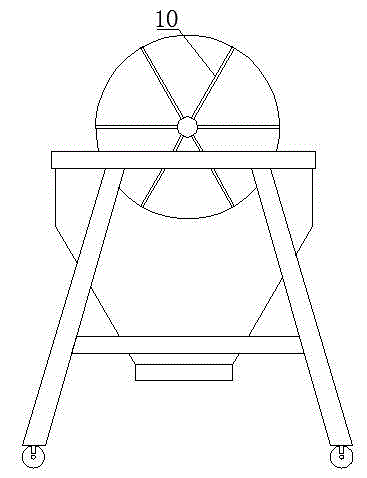

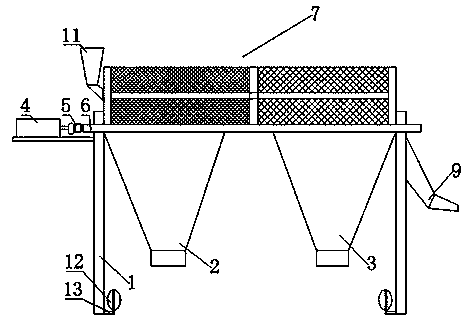

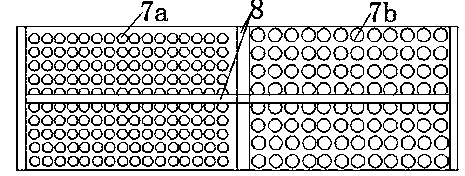

Sand screening equipment for construction

ActiveCN107470129AImprove sand screening efficiencyAvoid mesh cloggingSievingScreeningElectric machineryBevel gear

The invention discloses sand screening equipment for construction. The sand screening equipment comprises a sand screening box, an electric push rod, a first screen, a second screen, springs, a first gear, a second gear, an incomplete gear, a first rotary shaft, a first motor, a first bevel gear, a second bevel gear, a second rotary rod, cross rods, brushes, a reel and a second motor. The sand screening equipment is provided with the first screen and the second screen, and multi-stage screening can be conducted to meet requirements of different construction operations; the sand screening equipment is provided with the first motor, the first rotary shaft, the incomplete gear, the first gear, the second gear and the springs, the first screen and the second screen are made to shake continuously through cooperation, and the sand screening efficiency is improved; the sand screening equipment is provided with the first bevel gear, the second bevel gear, the second rotary shaft, the cross rods and the brushes, the bottom of the first screen and the top of the second screen are brushed continuously through the brushes, meshes of the first screen and the second screen are prevented from being blocked, and the sand screening efficiency is further improved; and the sand screening equipment is provided with the electric push rod, the reel and the second motor, and discharging is convenient.

Owner:北京城建二建设工程有限公司

Energy-saving fine crushing device of millstone for PVC novel material processing

ActiveCN110154265AImprove crushing effectAvoid situations where crushing is not in placeElectric machineryDrive motor

The invention discloses an energy-saving fine crushing device of a millstone for PVC novel material processing. The energy-saving fine crushing device comprises a base, a crushing box, a splitting device, a driving motor and a screening groove. A splitting device is arranged on the left side of the top of the crushing box, a primary crushing cavity is formed in the upper part in the crushing box,a limiting slide bar is also horizontally welded in the crushing box, and the screening groove is slidably formed in the limiting slide bar. By charging a PVC novel material intermittently, plug during crushing as a result of primary overcharge is avoided when the PVC novel material is crushed, so that the crushing effect is improved greatly. The screening groove moves left and right during screening, so that the screening speed of the PVC novel material powder in the screening groove is accelerated, and the condition that meshes are blocked by the PVC novel material powder is avoided. Meanwhile, the driving motor drives crushing and screening at the same time, so that the utilization ratio of the motor is saved, and meanwhile, the energy-saving fine crushing device plays an energy-savingrole, saves energy and is environmentally friendly.

Owner:黄山市瑞亿新材料有限公司

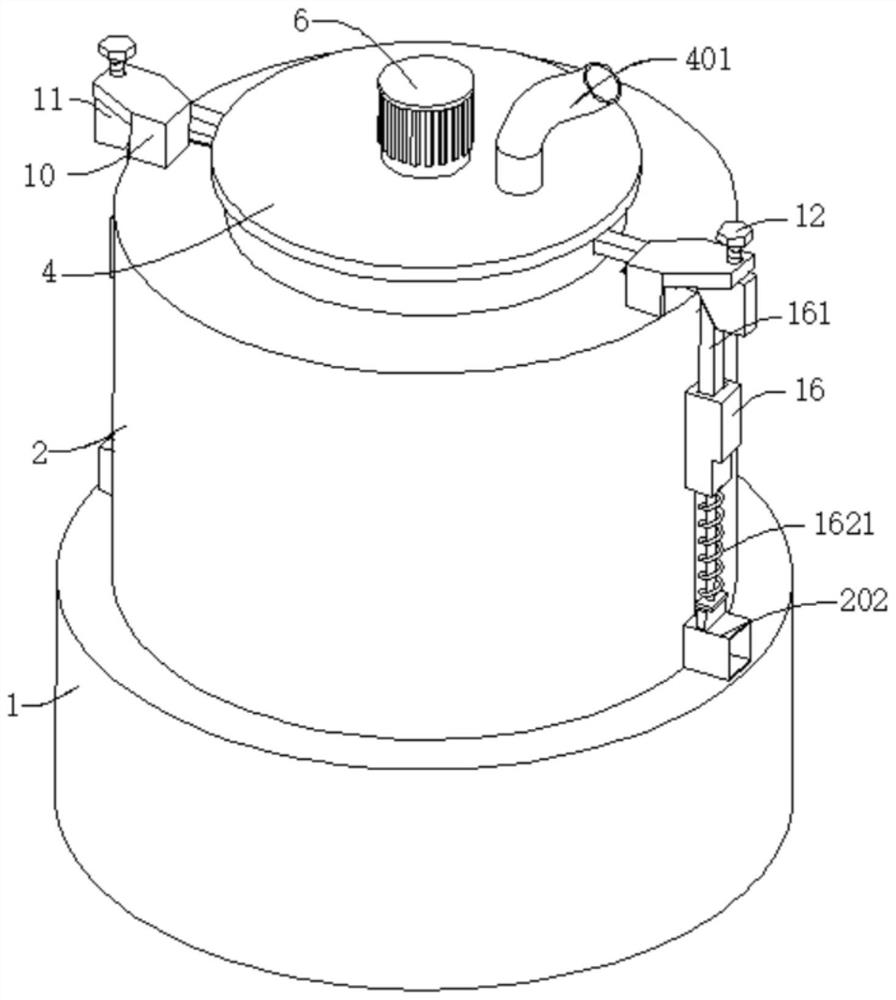

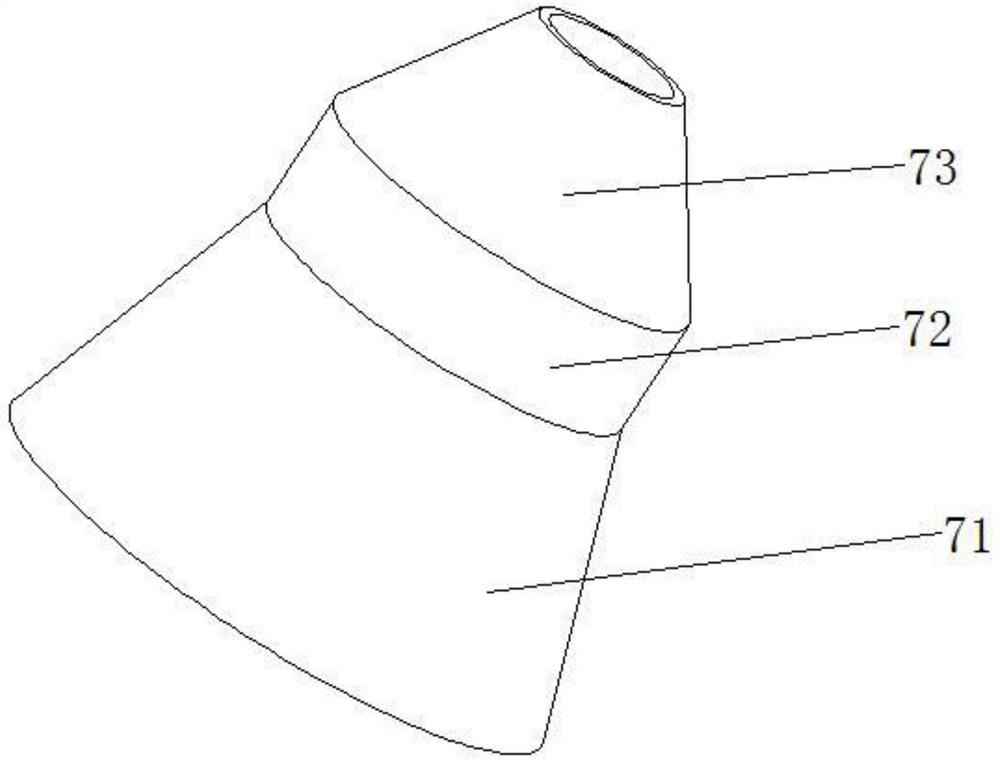

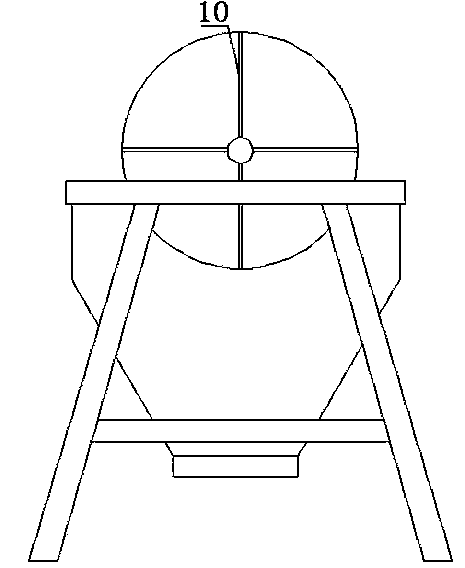

Caking zinc sulfate scattering device and using method thereof

ActiveCN110787867AAvoid mesh cloggingReasonable designSievingScreeningProcess engineeringStructural engineering

The invention discloses a caking zinc sulfate scattering device. The device comprises a box body, a collecting funnel, a screening net, a cleaning device and a conveying device. The interior of the box body is hollow, the top of the box body is fixed with the collecting funnel, a limiting valve is mounted at the bottom of the collecting funnel, a first crushing roller and a second crushing rollerare symmetrically arranged under the collecting funnel, the screening net is rotatably arranged on a mounting ring, and the screening net is in a funnel shape. The fixing frame is provided with the cleaning device, the cleaning device comprises cleaning rods and a transmission box, the four cleaning rods are obliquely and symmetrically fixed to a group of rotating shafts, and a transmission box isarranged on the portion, above the screening net, on the inner wall of the box body. The caking zinc sulfate scattering device is reasonable in design, the screening net can be effectively cleaned, the screening net is effectively prevented from being blocked, meanwhile, unqualified products can be crushed again, and the device is suitable for being used and popularized.

Owner:HUNAN LIHONG NEW MATERIAL TECH CO LTD

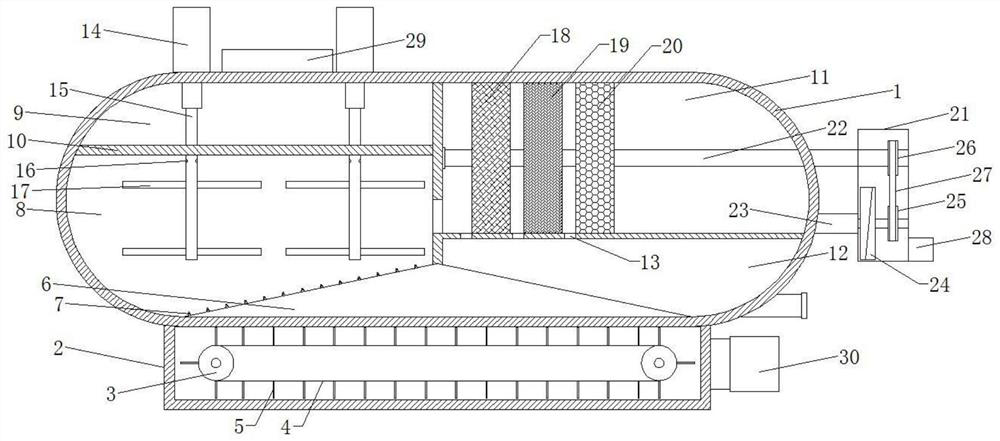

Sewage treatment device facilitating residue removal

PendingCN112456664AAvoid mesh cloggingEasy to pass throughSpecific water treatment objectivesTreatment involving filtrationElectric machineryStructural engineering

The invention discloses a sewage treatment device facilitating residue removal, and belongs to the technical field of sewage treatment. A sewage treatment device facilitating residue removal comprisesa shell base, a shell is connected to the top of the shell base, a partition plate is connected to the inner wall of the shell, drainage pipes are fixedly connected to the outer walls of the two sides of the shell, the drainage pipes are connected to the outer wall of the top of the shell base, and a filter screen cylinder is detachably connected into the shell; a first motor is connected to theinner wall of the bottom of the shell base, a first rotating shaft is connected to the output end of the first motor, a square block is connected to the end, away from the first motor, of the first rotating shaft, a square groove matched with the square block is dug in the outer wall of the bottom of the filter screen cylinder, and filter screen holes are formed in the outer wall of the filter screen cylinder; and the inner wall of the bottom of the filter screen cylinder is also connected with a convex block. Meshes can be prevented from being blocked, sewage can conveniently and quickly penetrate through the meshes, residues can be collected and treated, and the working efficiency of sewage residue removal is improved.

Owner:陈时云

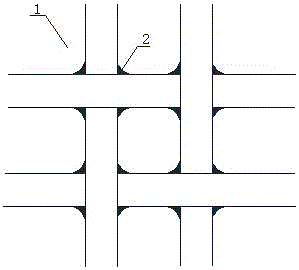

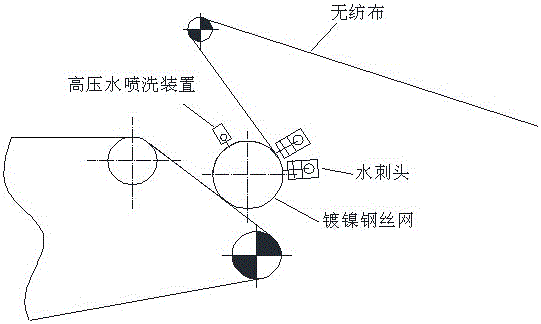

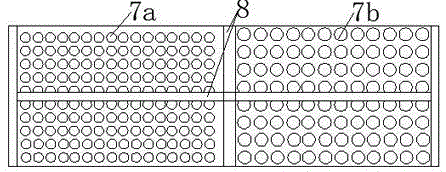

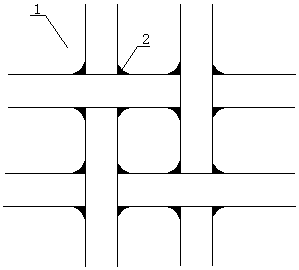

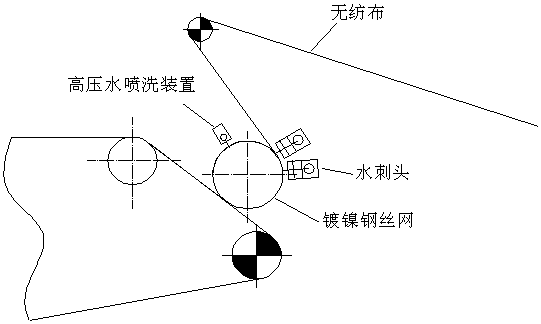

Spunlace wire mesh for wet process spunlace anti-sticking fiber

The invention relates to a spunlace wire mesh for wet process spunlace anti-sticking fiber, which is capable of enabling the surface of a stainless steel wire mesh to be smooth to avoid fiber sticking and capable of enabling an included angle between upper and lower layers of the interweaving part of warp and weft steel wires for forming the wire mesh to be smooth and generate a fiber transfer chamfer, so that the fiber can not be accumulated at the interweaving part. An anti-sticking fiber spunlace wire mesh is a 50-130-mesh single-layer stainless steel wire mesh, a nickel coating is formed on the surface of the stainless steel wire mesh, and the included angle between the upper and lower layers of the interweaving part of warp and weft steel wires in the 50-130-mesh stainless steel wire mesh with the nickel coating is filled with nickel and is smooth. The included angle between the upper and lower layers of the interweaving part of the warp and weft steel wires in the stainless steel wire mesh with the nickel coating is filled with nickel and is smooth, thereby basically solving the problems which are not solved in the field for a long time that the fiber is easy to accumulate at interweaving points in the warp and weft steel wire interweaving structure of the wire mesh and is clamped between the interweaving points, avoiding the phenomenon that the fiber is accumulated and thus mesh holes are blocked, ensuring the product quality, and ensuring the production stability and continuity.

Owner:HANGZHOU NBOND NONWOVENS

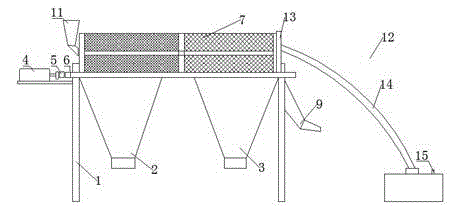

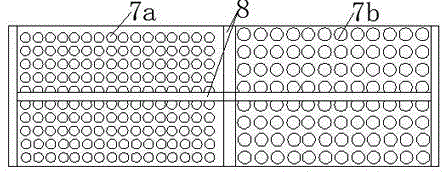

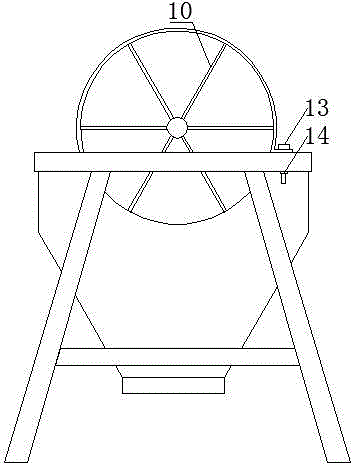

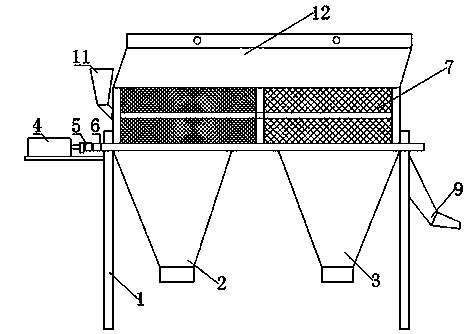

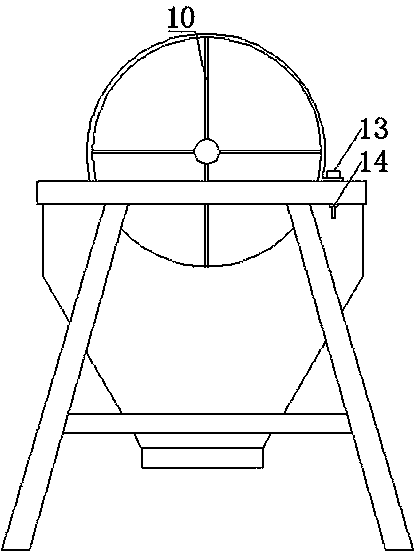

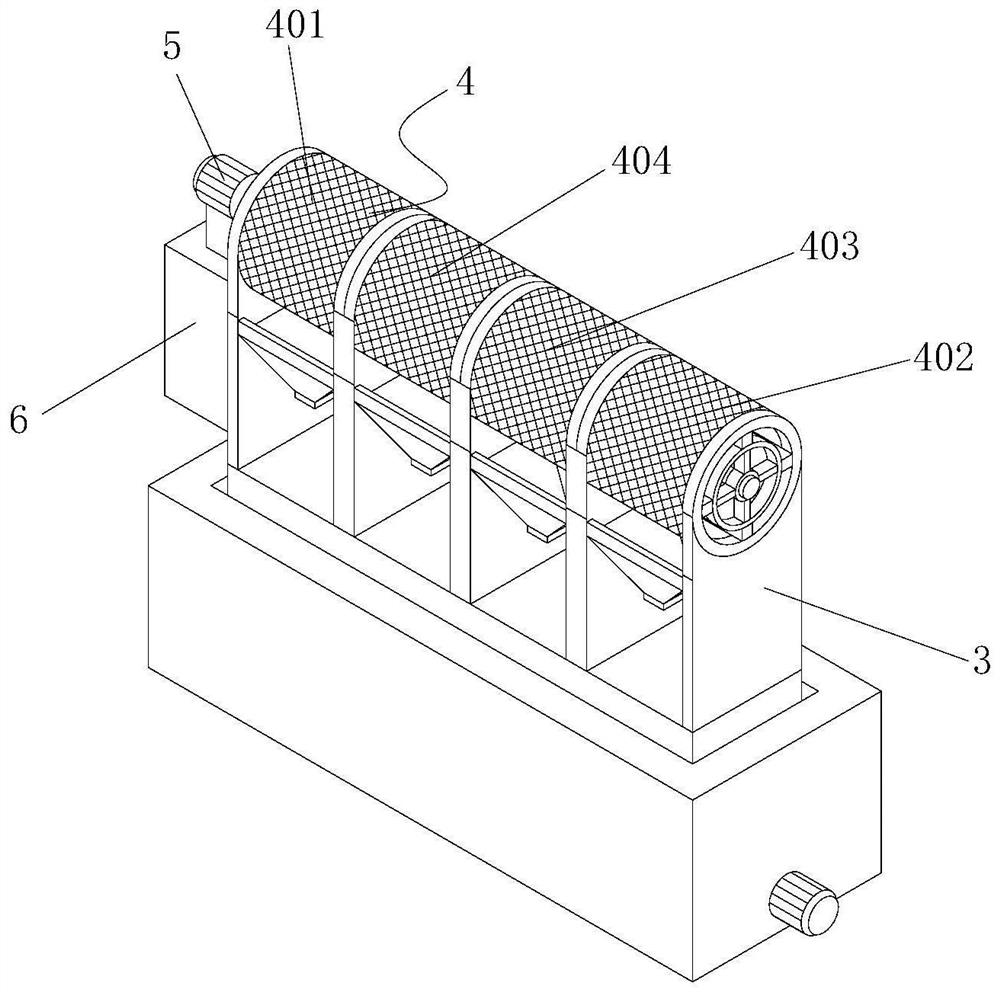

Two-stage rotary screen with dust collector and firm supporting frame

InactiveCN104646274AImprove protectionIncrease the number ofSievingScreeningControl theoryWaste material

The invention relates to a chemical fertilizer production device, and in particular relates to a two-stage rotary screen with a dust collector and a firm supporting frame. The two-stage rotary screen with the dust collector and the firm supporting frame comprises a bracket, a motor, a coupling, a screen shaft, a screen body, supporting frames and the dust collector; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen part and a second screen part; the meshes of the first screen part are smaller than those of the second screen part; the dust collector is arranged in the same direction as a waste opening; the supporting frames are arranged every interval of 60 degrees along the screen shaft in the radial shaft and are fixedly connected with the screen shaft by welding. The two-stage rotary screen with the dust collector and the firm supporting frame has the advantages that the circumstance that the meshes are blocked can be prevented, operators can be protected well, and thus the safety and flexibility in use of the rotary screen can be improved.

Owner:弭勇捷

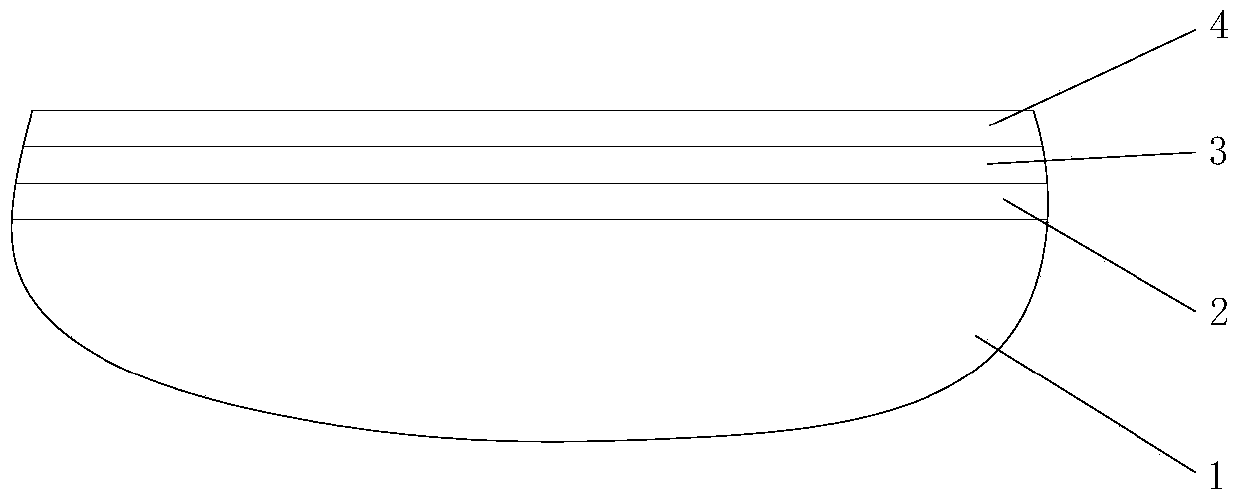

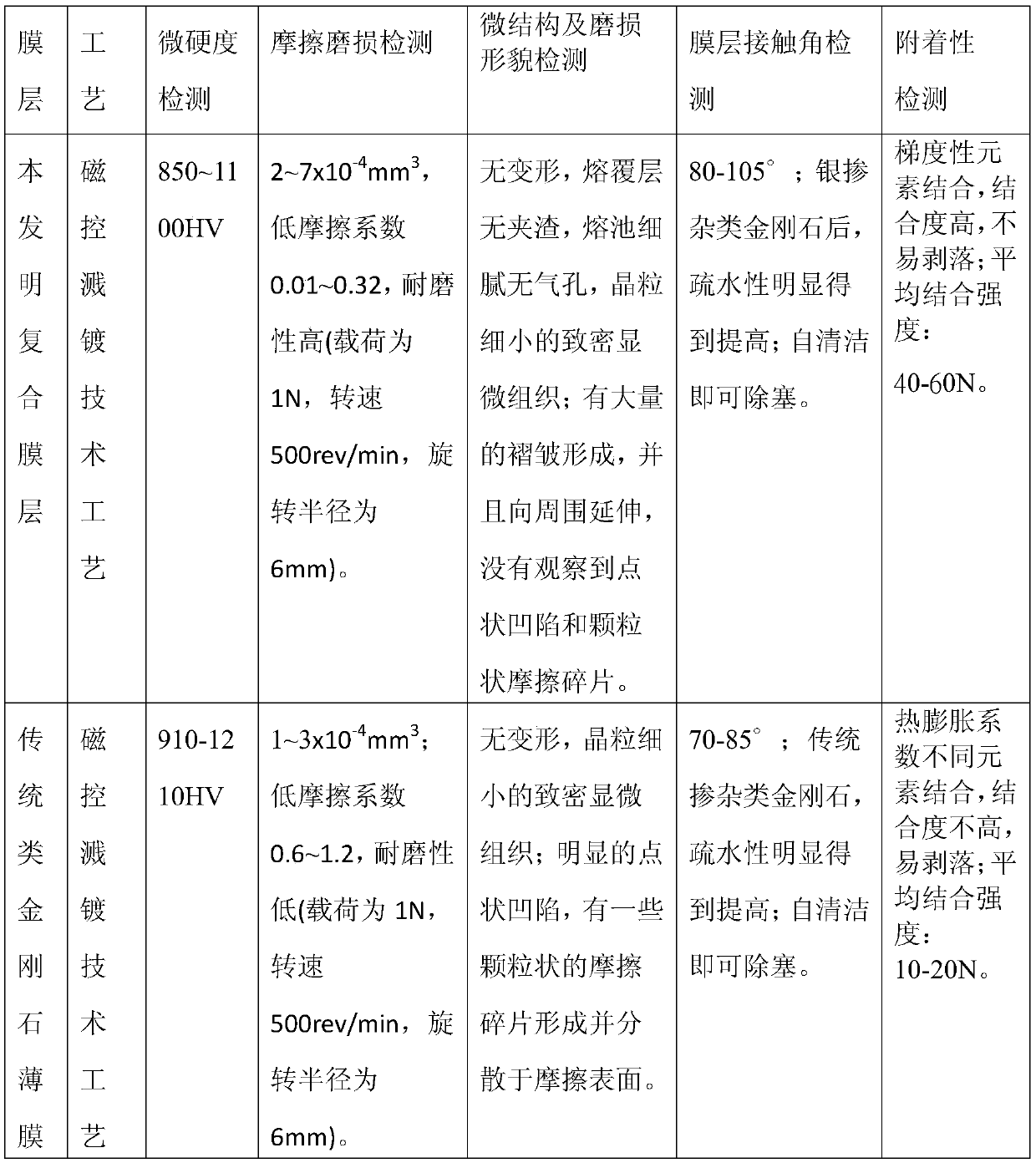

Screen-clogging-resisting silk-screen printing screen and preparing method thereof

InactiveCN109609920AGood adhesionImprove thermal stabilityScreen printersVacuum evaporation coatingScreen printingComposite film

The invention discloses a screen-clogging-resisting silk-screen printing screen and a preparing method thereof. The screen comprises a base body, a composite film layer is arranged on the surface of the base body and sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, the inner layer is a titanium aluminum layer, the middle layer is a titanium aluminum+ similar diamond layer, and the outer layer is a silver doped similar diamond layer. The screen has the good self-cleaning screen-clogging-resisting property, and meanwhile, the combination strengthbetween film layers is high.

Owner:FUJIAN UNIV OF TECH

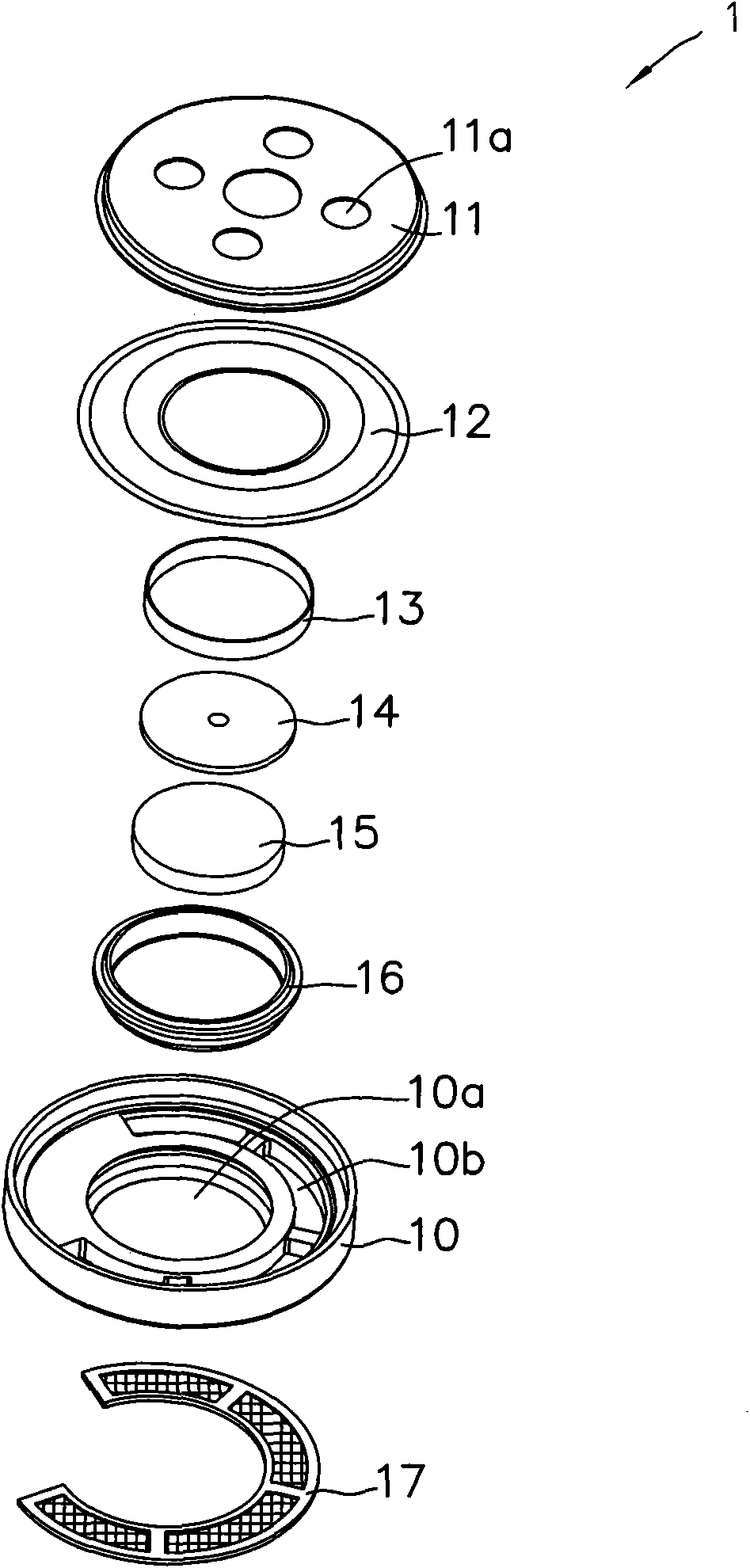

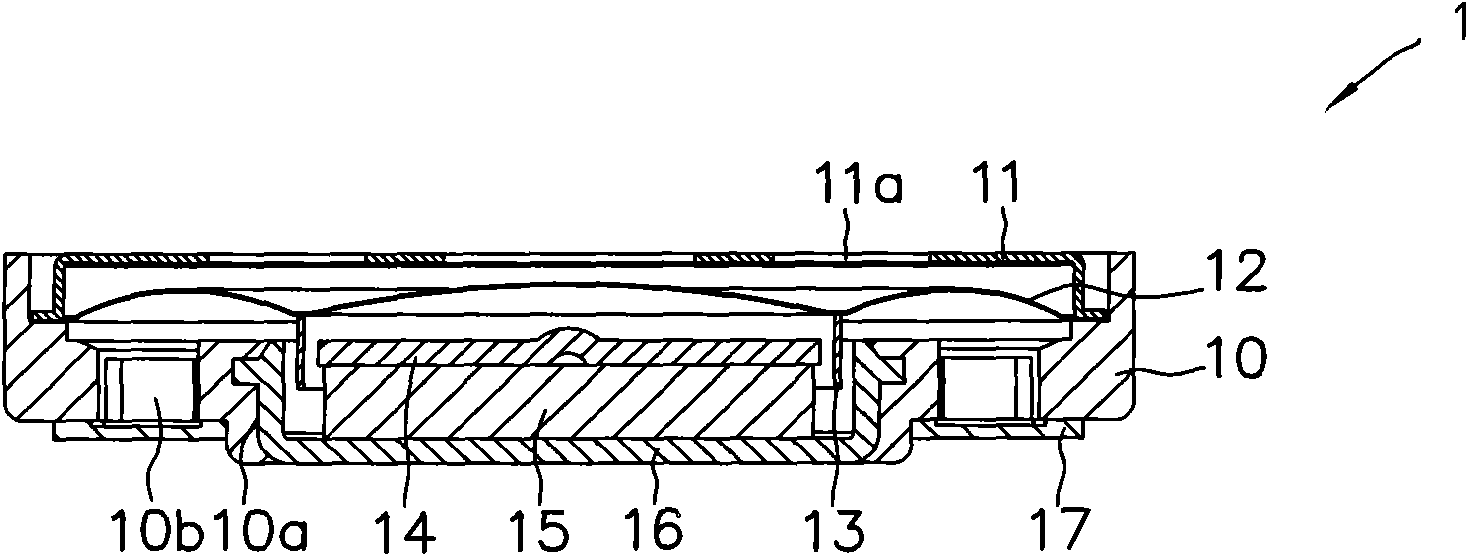

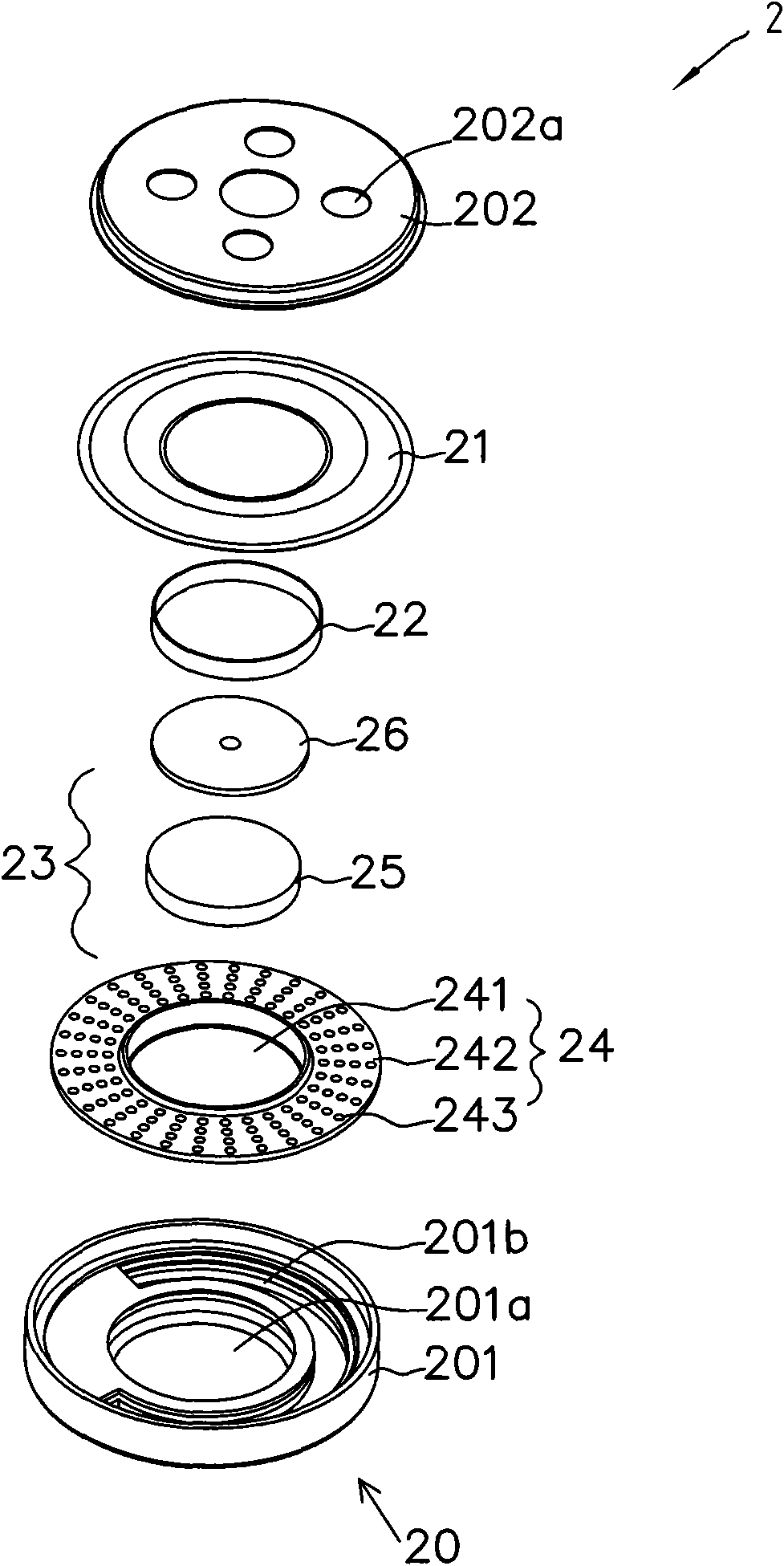

Electro-acoustic transducer

InactiveCN102036151BAvoid mesh cloggingAvoid Acoustic Performance ImpactElectrical transducersAir volumeTransducer

Owner:MERRY ELECTRONICS CO LTD

Two-stage rotary screen with protection shield and firm support bracket

InactiveCN104646269AReduction of Hazardous SubstancesGood protectionSievingScreeningFertilizerEngineering

The invention relates to a chemical fertilizer production apparatus, and specifically relates to a two-stage rotary screen with protection shield and firm support bracket; the two-stage rotary screen with protection shield and firm support bracket comprises a bracket, a motor, a shaft coupler, a screen shaft, a screen body, a support bracket, and a protection shield; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket via bearings; the screen body is connected with the screen shaft via the support bracket; the motor is connected with the screen shaft via the shaft coupler; the screen body comprises a first screen mesh portion and a second screen mesh portion; the mesh holes of the first screen mesh portion are smaller than the mesh holes of the second screen mesh portion; one side of the protection shield is fixedly connected with the bracket; the other side is detachably connected with the bracket; the support bracket is arranged along the radial direction of the screen shaft in every 60 degrees; and the support frame is fixed connected with the screen shaft by means of welding. The provided two-stage rotary screen with protection shield and firm support bracket reinforces the firmness of the screen body, increases the work quality and efficiency of the rotary screen.

Owner:弭勇捷

Two-stage drum screen with protecting cover and foldable rolling wheels

InactiveCN104289412AEasy to moveImprove the quality of workSievingScreeningAgricultural engineeringSecond screen

The invention relates to a chemical fertilizer production device, in particular to a two-stage drum screen with a protecting cover and foldable rolling wheels. The two-stage drum screen comprises a support, a motor, a coupler, a screen shaft, a screen body, supporting frames, the protecting cover and the foldable rolling wheels, wherein the motor is arranged on the support, the two ends of the screen shaft are connected with the support through bearings, the screen body is connected with the screen shaft through the supporting frames, the motor is connected with the screen shaft through the coupler, the screen body comprises a first screen mesh part and a second screen mesh part with the mesh openings larger than the mesh openings of the first screen mesh part, one side of the protecting cover is fixedly connected with the support, the other side of the protecting cover is detachably connected with the support, and the foldable rolling wheels are arranged at the four corners of the support and movably connected with the support. According to the two-stage drum screen with the protecting cover and the foldable rolling wheels, the work quality and efficiency and the use flexibility and safety of the drum screen are improved.

Owner:崔海花

Two-stage rotary screen with dust collector and movable roller

InactiveCN104646271AEasy to moveReduce the presence of hazardous substancesSievingScreeningAgricultural engineeringEngineering

The invention relates to a chemical fertilizer production device, and in particular relates to a two-stage rotary screen with a dust collector and a movable roller. The two-stage rotary screen with the dust collector and the movable roller comprises a bracket, a motor, a coupling, a screen shaft, a screen body, a supporting frame, the dust collector and the movable rollers; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen part and a second screen part; the meshes of the first screen part are smaller than those of the second screen part; the dust collector is arranged in the same direction as a waste opening; the movable rollers are arranged at four corners of the bracket and are fixedly connected with the bracket. The two-stage rotary screen with the dust collector and the movable roller has the advantages that the circumstance that the meshes are blocked can be prevented, operators can be protected well, and thus the safety and flexibility in use of the rotary screen can be improved.

Owner:弭勇捷

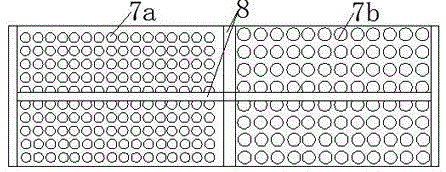

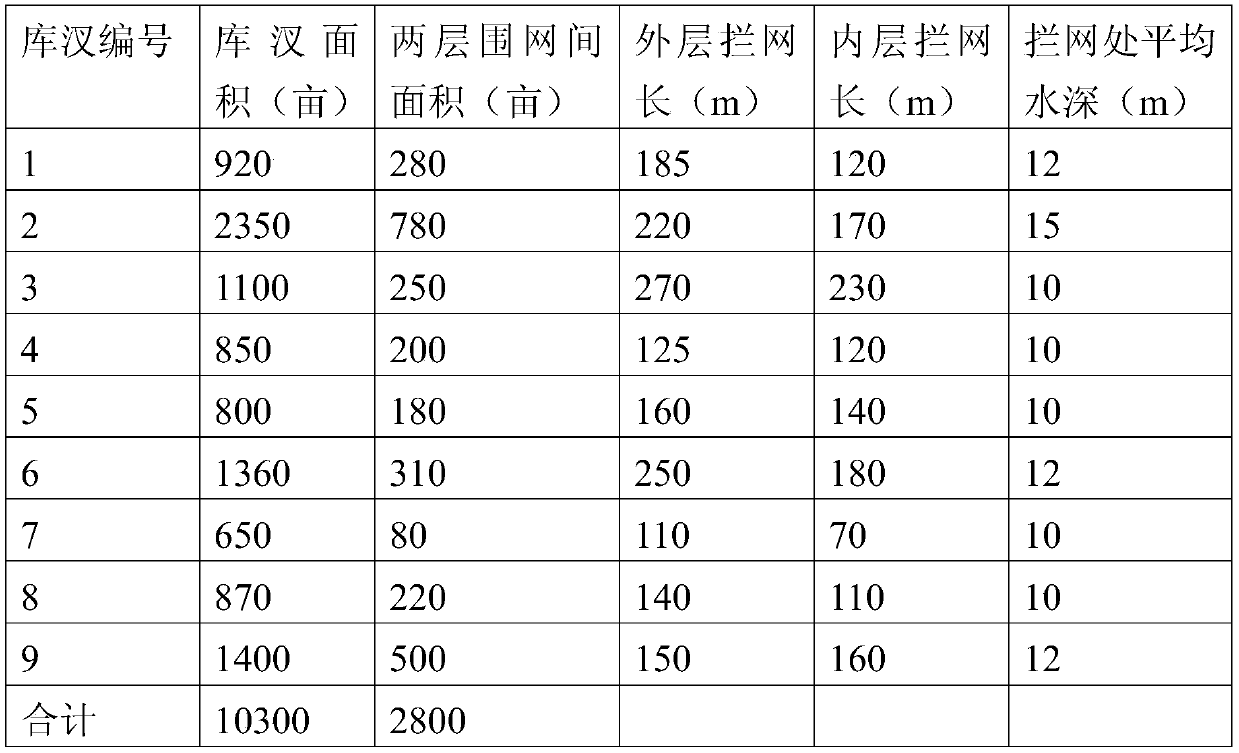

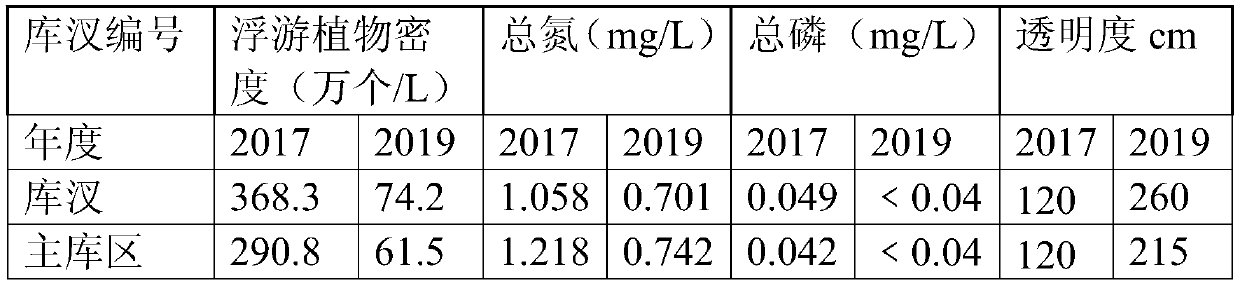

Silver carp and bighead carp separated propagation type reservoir water purification and fishery breeding method and breeding system

PendingCN111387093AImprove survival rateAvoid mesh cloggingClimate change adaptationPisciculture and aquariaLarvaEnvironmental geology

The invention discloses a silver carp and bighead carp separated propagation type reservoir water purification and fishery breeding method and a breeding system. The breeding method comprises the following step: setting double-layer baffle nets at branch mouths of reservoir branch openings, wherein the baffle net close to the main reservoir area at downstream of a reservoir is an outer-layer baffle net; the baffle net of a branch area close to an upstream reservoir branch is an inner-layer baffle net; an area formed from the inner-layer baffle net to the branch area is a silver carp propagation area; an area formed between the double-layer baffle nets is a middle bighead larva culture and xenocypris propagation area; and an area formed from the outer-layer baffle net to the main reservoiris a bighead carp propagation area. The breeding method and the breeding system are mainly applied to propagation breeding and water quality improvement in a reservoir region, and the baffle nets arearranged at reservoir branch openings, so that partial high densities of fishes can be achieved, and an effect of rapidly purifying water can be achieved.

Owner:GUANGXI ACADEMY OF FISHERY SCI

Desulfurization waste liquid recycling device and process

PendingCN112062175AAvoid Mesh CloggingAvoid being blockedSpecific water treatment objectivesTreatment involving filtrationElectric machineryWater storage tank

The invention discloses a desulfurization waste liquid recycling device and process, and relates to the technical field of wastewater treatment. In order to solve the problem that a filter screen is easily blocked by impurities and the wastewater treatment efficiency is influenced during existing desulfurization waste liquid treatment, the invention provides a scheme as follows: the device comprises a water storage tank, a first filtering and cleaning mechanism is arranged in the water storage tank, a sleeve is fixedly connected to the bottom of the water storage tank, a water receiving tank is arranged at the bottom of the sleeve, a plurality of material guide rollers are rotatably connected to the interior of the water receiving tank, a plurality of second filtering and cleaning mechanisms are slidably arranged on the material guide rollers, a double-shaft motor is fixedly connected to the right side of the top of the water receiving tank, a transmission mechanism is arranged betweenthe double-shaft motor and the first filtering and cleaning mechanism, and a driving water supply mechanism is arranged at the bottom of the double-shaft motor. According to the invention, multiple filtration can be carried out, blockage can be avoided, high-quality and high-efficiency wastewater filtration is ensured, and repeated filtration treatment is beneficial to more thorough wastewater filtration.

Owner:安吉临港热电有限公司

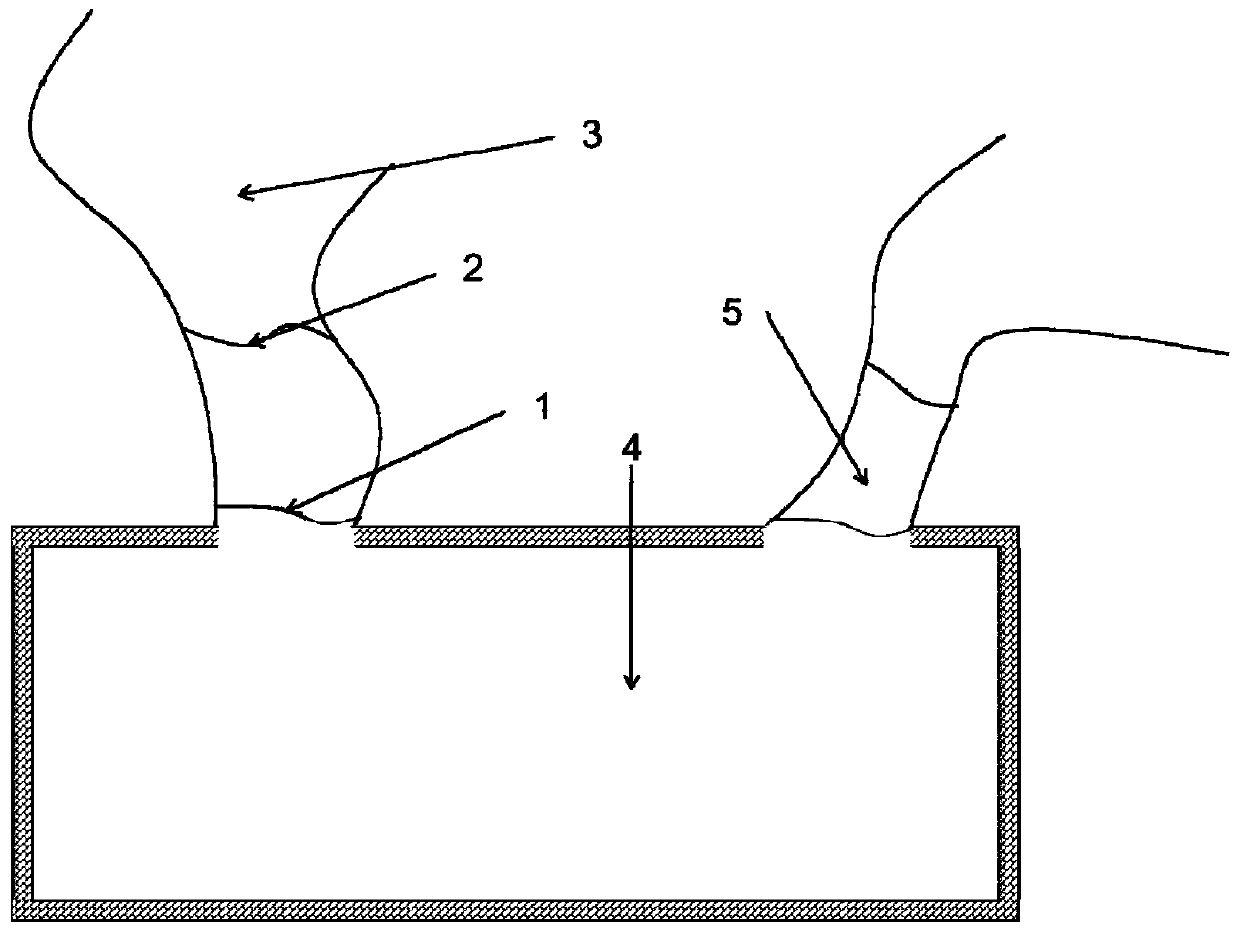

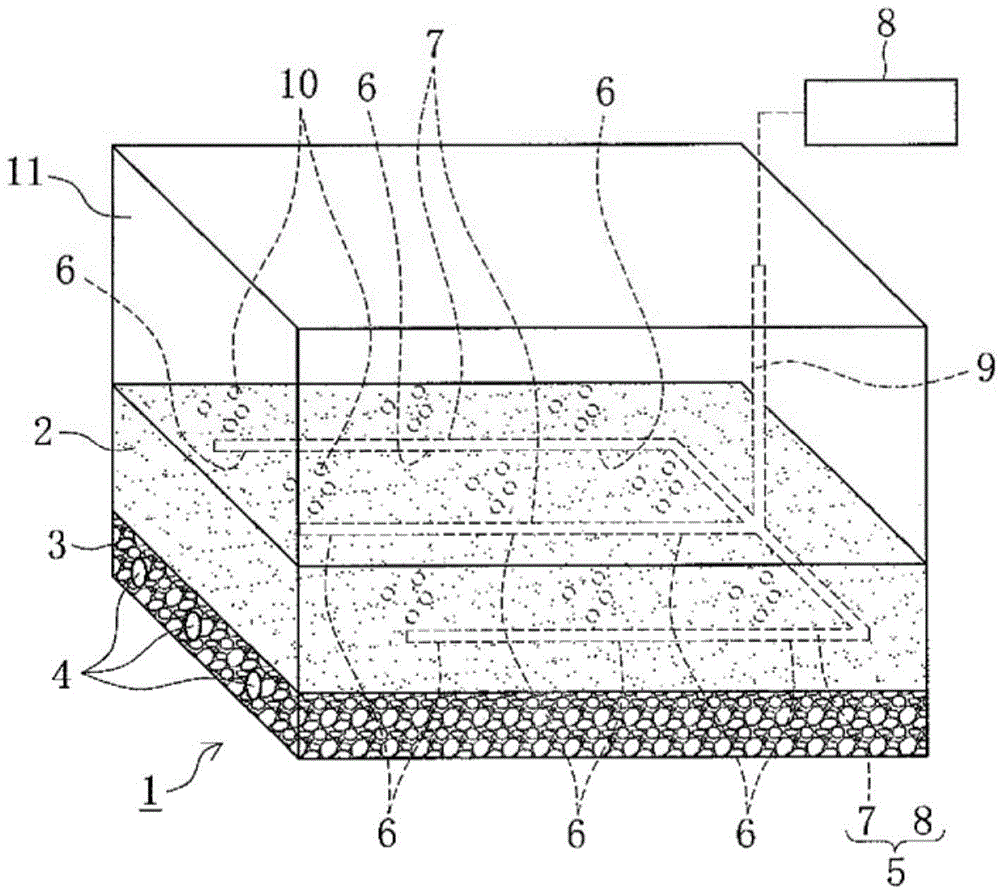

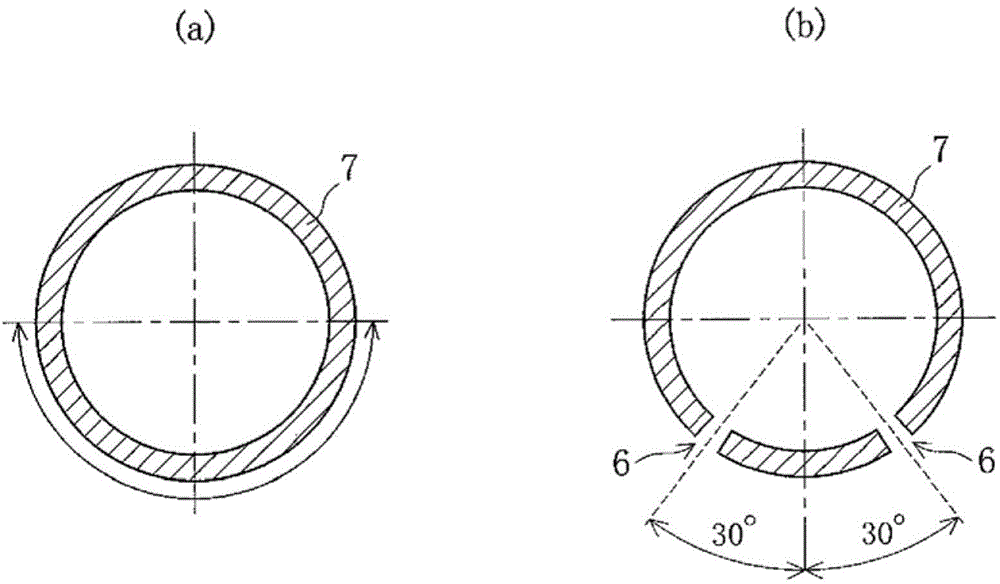

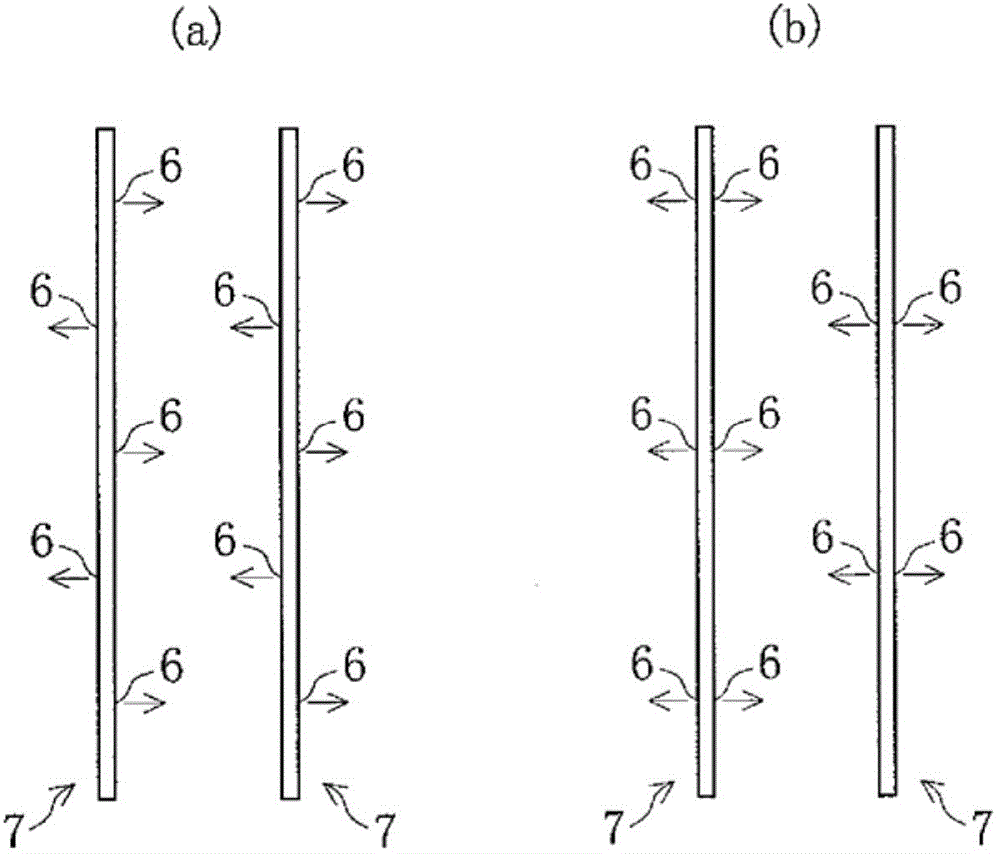

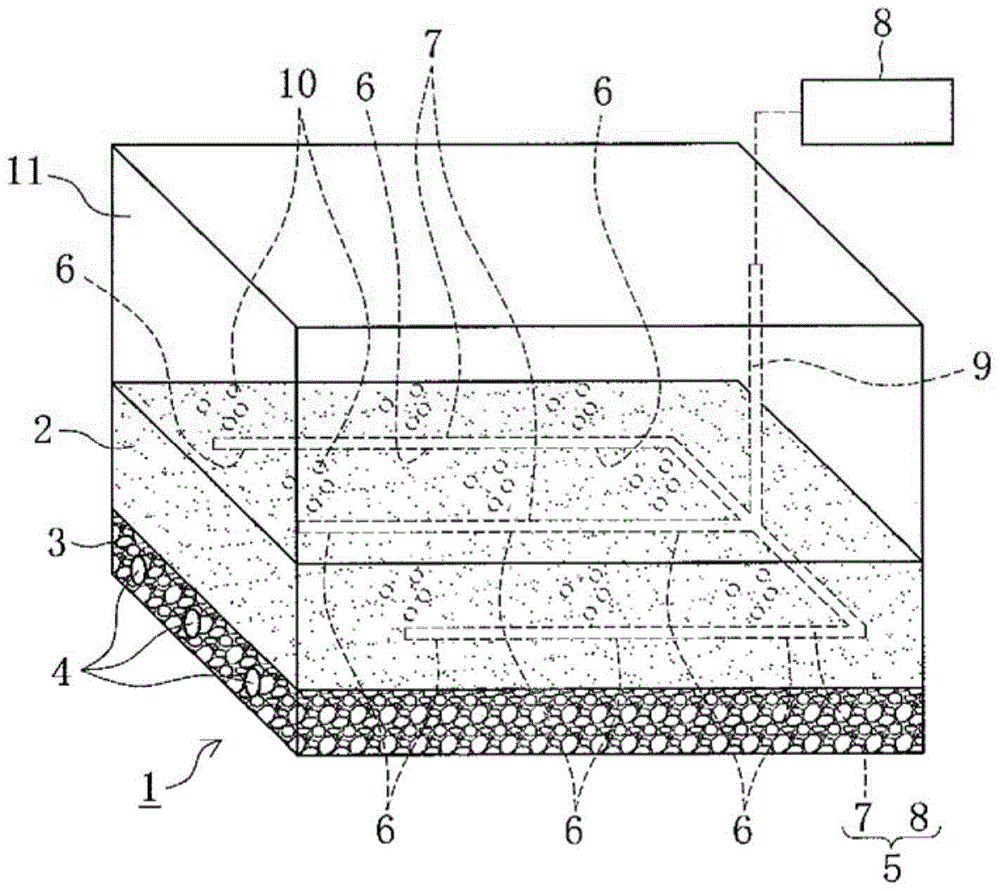

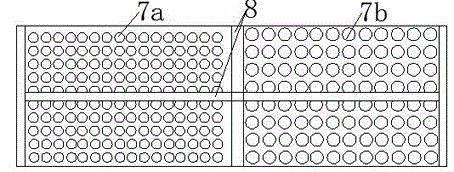

Cleaning system for sand filtration layer

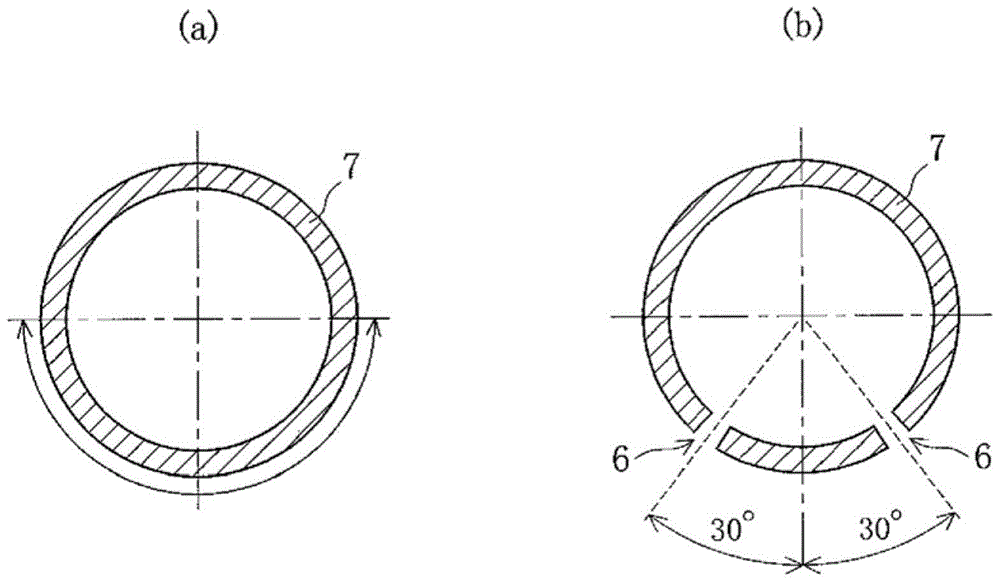

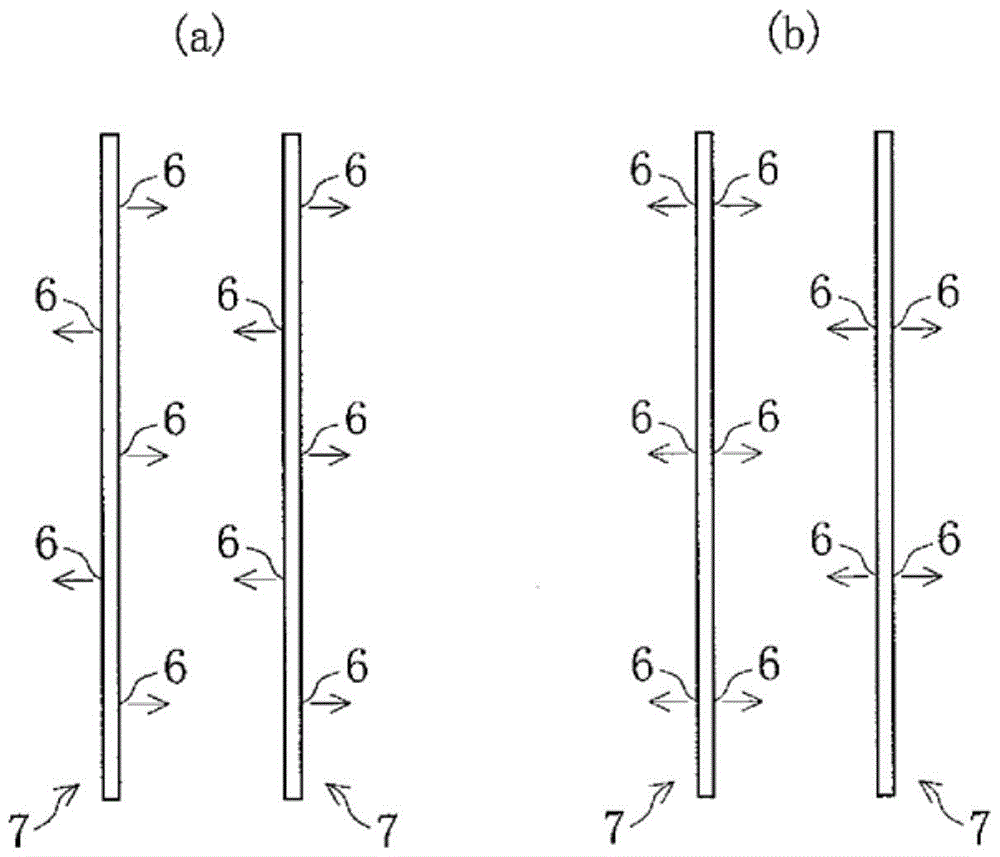

ActiveCN104822431AAvoid mesh cloggingLow running costMembrane filtersLoose filtering material filtersFiltrationEngineering

[Problem] To provide a more compact cleaning apparatus for a sand filtration layer, and reduce the scale of operations and the running costs. [Solution] The cleaning system (1) is designed for use in a seawater permeation intake apparatus (5) for intake of seawater having permeated through a sand filtration layer (2) and a supporting gravel layer (3) on the seabed through intake pipes (4) buried in the supporting gravel layer (3), in order to remove from the sand filtration layer (2) suspended matter that could cause clogging. The system is provided with: diffuser tubes (7) buried in the sand filtration layer (2) and having air holes (6); and a compressed air delivery means (8) for feeding air into the diffuser tubes (7). The filtration sand of the sand filtration layer (2) is agitated by jetting air from the air holes (6), removing suspended matter that has become admixed or deposited in the sand filtration layer (2). [Effect] As compared with conventional systems that inject water or seawater into a sand filtration layer, the cleaning equipment can be more compact, and the scale of operations and running costs can be reduced.

Owner:HITACHI ZOSEN CORP +1

Two-stage drum screen with protecting cover and dust absorbing device

InactiveCN104646275AReduce the presence of hazardous substancesImprove the quality of workSievingScreeningElectric machineryWaste material

The invention relates to chemical fertilizer production equipment, and in particular relates to a two-stage drum screen with a protecting cover and a dust absorbing device. The two-stage drum screen with the protecting cover and the dust absorbing device comprises a bracket, a motor, a coupling, a screen shaft, a supporting frame, the protecting cover and the dust absorbing device; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen cloth part and a second screen cloth part; the meshes of the first screen cloth part are smaller than those of the second screen cloth part; one side of the protecting cover is fixedly connected with the bracket, and while the other side of the protecting cover is detachably connected with the bracket; the dust absorbing cover and a waste opening are arranged in the same direction. With the adoption of the two-stage drum screen with the protecting cover and the dust absorbing device, the working quality and efficiency can be increased, and the use safety is improved.

Owner:弭勇捷

Two-stage rotary screen with firm support and foldable roller

The invention relates to a chemical fertilizer production device, and in particular relates to a two-stage rotary screen with a firm support and a foldable roller. The two-stage rotary screen with the firm support and the foldable roller comprises a bracket, a motor, a coupling, a screen shaft, a screen body, supporting frames and the foldable rollers; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen part and a second screen part; the meshes of the first screen part are smaller than those of the second screen part; the supporting frames are arranged every interval of 60 degrees along the screen shaft in the radial shaft and are fixedly connected with the screen shaft by welding; the foldable rollers are arranged at four corners of the bracket and are movably connected with the bracket. The two-stage rotary screen with the firming supporting frame and two types of screens has the advantages that the circumstance that the meshes are blocked can be prevented, the production cost can be saved, and the production efficiency can be greatly increased.

Owner:弭勇捷

Wet-laid spunlace anti-stick fiber spunlace steel wire mesh

The invention relates to a spunlace wire mesh for wet process spunlace anti-sticking fiber, which is capable of enabling the surface of a stainless steel wire mesh to be smooth to avoid fiber sticking and capable of enabling an included angle between upper and lower layers of the interweaving part of warp and weft steel wires for forming the wire mesh to be smooth and generate a fiber transfer chamfer, so that the fiber can not be accumulated at the interweaving part. An anti-sticking fiber spunlace wire mesh is a 50-130-mesh single-layer stainless steel wire mesh, a nickel coating is formed on the surface of the stainless steel wire mesh, and the included angle between the upper and lower layers of the interweaving part of warp and weft steel wires in the 50-130-mesh stainless steel wire mesh with the nickel coating is filled with nickel and is smooth. The included angle between the upper and lower layers of the interweaving part of the warp and weft steel wires in the stainless steel wire mesh with the nickel coating is filled with nickel and is smooth, thereby basically solving the problems which are not solved in the field for a long time that the fiber is easy to accumulate at interweaving points in the warp and weft steel wire interweaving structure of the wire mesh and is clamped between the interweaving points, avoiding the phenomenon that the fiber is accumulated and thus mesh holes are blocked, ensuring the product quality, and ensuring the production stability and continuity.

Owner:HANGZHOU NBOND NONWOVENS

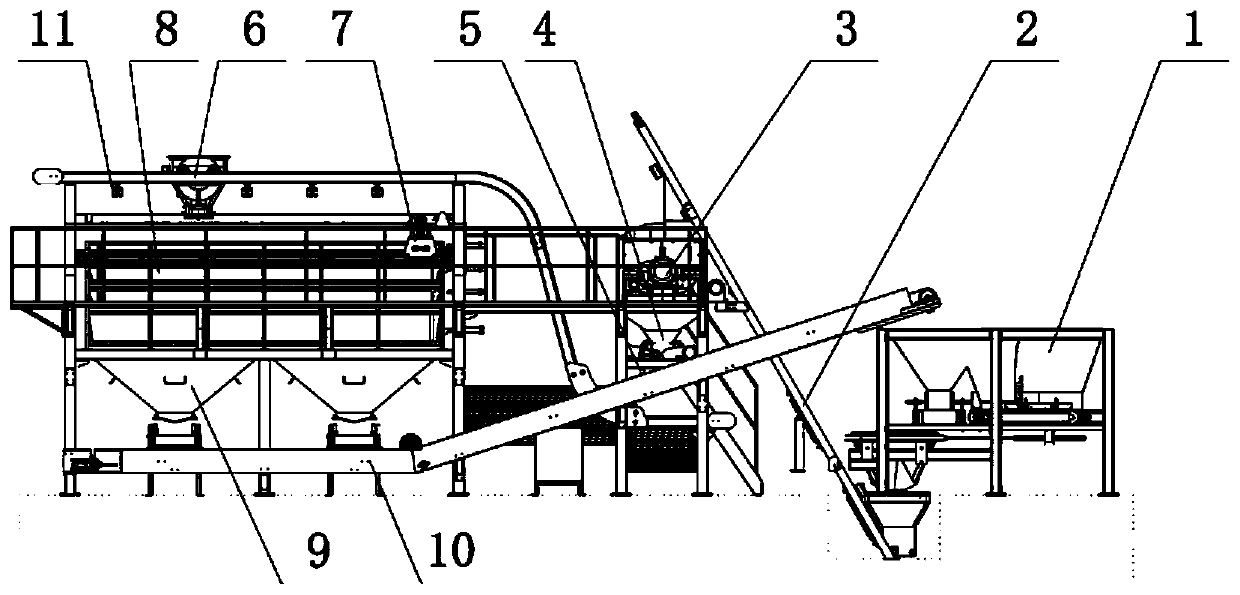

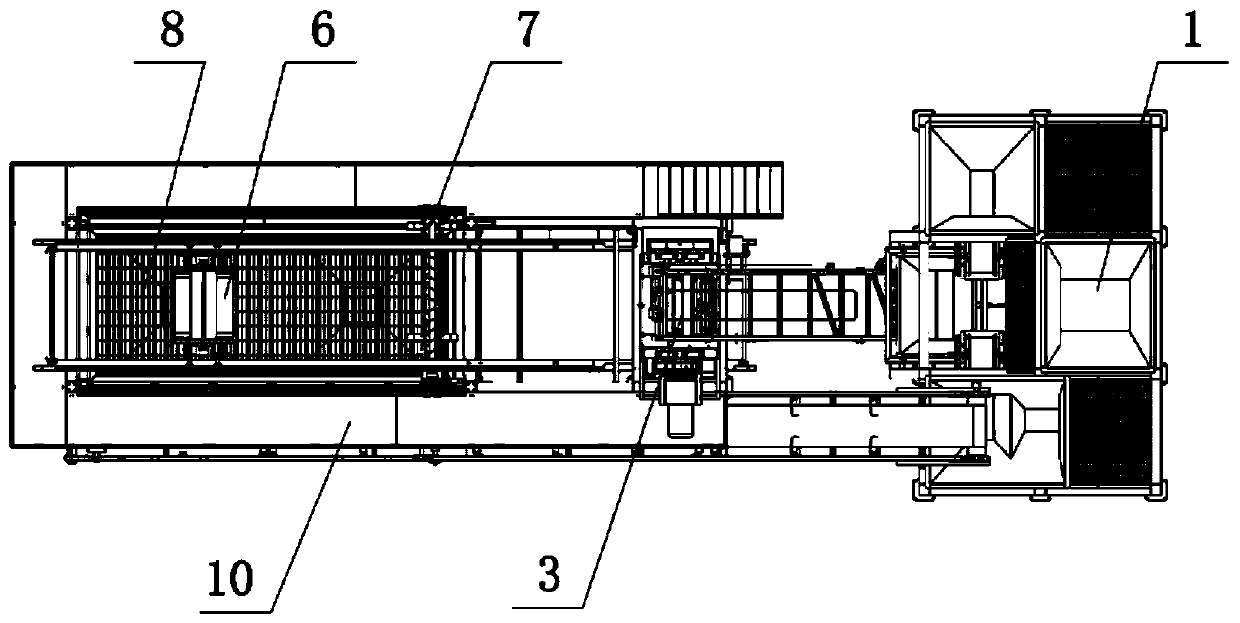

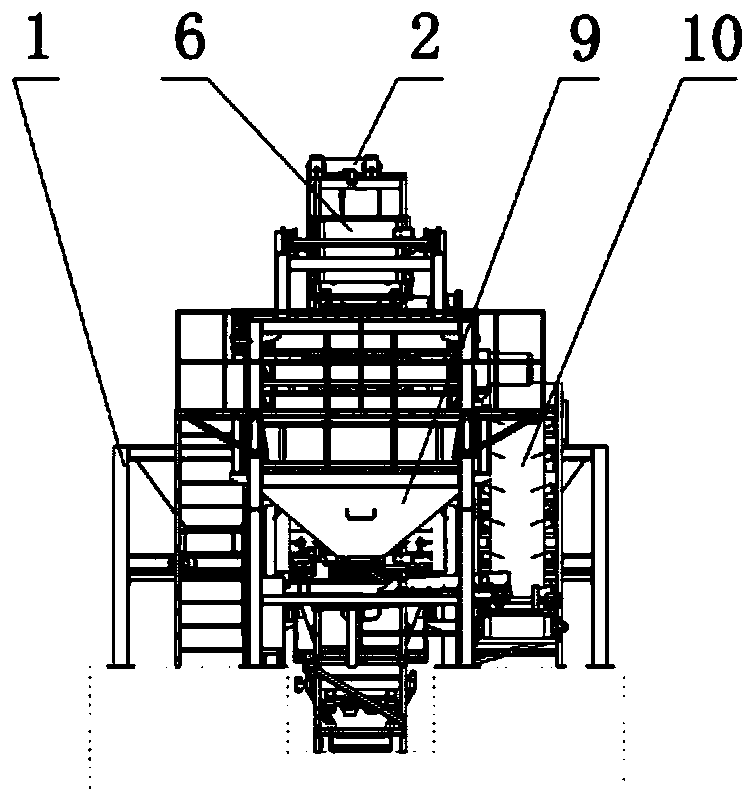

Tray-type three-dimensional fermentation system without turning over and fermentation method thereof

ActiveCN106077048BSolve the leakSolve pollutionSolid waste disposalClimate change adaptationBiologyMechanical engineering

The invention provides a free-overturning tray type stereoscopic fermentation system and method. The free-overturning tray type stereoscopic fermentation system comprises a material lifting device and fermentation trays. The fermentation trays are stereoscopically mounted in a laminating manner. The material lifting device is mounted at one side of each fermentation tray. A lifting discharge opening is formed above the fermentation trays. A tray side frame, a rotatable bottom plate, a bottom plate linkage mechanism and a bottom plate driving mechanism are arranged on each fermentation tray. The rotatable bottom plates are in transmission connection with the bottom plate driving mechanisms through the bottom plate linkage mechanisms. The rotatable bottom plates, the bottom plate linkage mechanisms and the bottom plate driving mechanisms are mounted on the tray side frames. Organic materials are lifted in the fermentation trays through the material lifting device, aerobic fermentation is conducted on the organic materials in the fermentation trays, and the organic materials are discharged from the bottoms of the fermentation trays through rotation of the rotatable bottom plates of the fermentation tray to complete unloading.

Owner:GUANGXI LIYUANBAO SCI & TECH

Cleaning system for filter sand layer

ActiveCN104822431BAvoid mesh cloggingLow running costMembrane filtersLoose filtering material filtersFiltrationFresh water

To reduce the size, scale of construction, and running cost of an apparatus for cleaning a sand filtration layer. A cleaning system which removes clogging sediments from a sand filtration layer 2, used with an apparatus for an infiltration intake of seawater which performs a seawater intake, by means of a water intake pipe 4 buried in the supporting gravel layer 3, after the seawater has been infiltrated through the sand filtration layer 2 and a supporting gravel layer 3 on an ocean floor. This cleaning system is provided with a diffuser pipe 7 having blow holes 6, and which is buried in the supporting gravel layer 3, as well as a compressed air delivery device 8 for feeding an air into the diffuser pipe 7. The system operates by blowing the air from the blow holes 6 to agitate the filtration sand of the sand filtration layer 2, to remove the sediments which have become trapped in or accumulated on the sand filtration layer 2. The system can achieve a smaller size, a smaller scale of construction, and a lower running cost than a conventional system which injects fresh water or seawater into the sand filtration layer.

Owner:HITACHI ZOSEN CORP +1

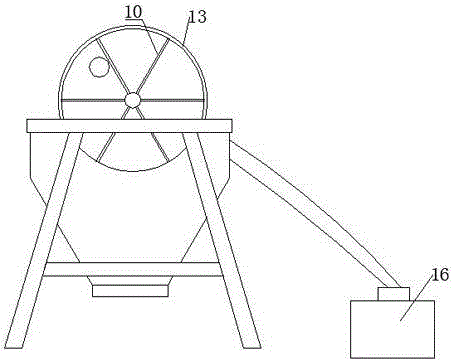

Drum screen with protecting cover and two kinds of screen meshes

InactiveCN104289417AImprove the quality of workImprove work efficiencySievingScreeningAgricultural engineeringStructural engineering

The invention relates to a chemical fertilizer production device, in particular to a drum screen with a protecting cover and two kinds of screen meshes. The drum screen comprises a support, a motor, a coupler, a screen shaft, a screen body, supporting frames and the protecting cover, wherein the motor is arranged on the support, the two ends of the screen shaft are connected with the support through bearings, the screen body is connected with the screen shaft through the supporting frames, the motor is connected with the screen shaft through the coupler, the screen body comprises a first screen mesh part and a second screen mesh part with the mesh openings larger than the mesh openings of the first screen mesh part, one side of the protecting cover is fixedly connected with the support, and the other side of the protecting cover is detachably connected with the support. The drum screen is provided with the two kinds of screen meshes with the mesh openings, so that the situation that the mesh openings are blocked is prevented; the upper portion of the drum screen is provided with the protecting cover, so that it is prevented that many fertilizer particles are thrown out when the drum screen works, and the work quality and efficiency of the drum screen are improved.

Owner:崔海花

Two-stage rotary screen with dust collector and foldable roller

InactiveCN104646270AReduce the presence of hazardous substancesEasy to moveSievingScreeningAgricultural engineeringWaste material

The invention relates to a chemical fertilizer production device, and in particular relates to a two-stage rotary screen with a dust collector and a foldable roller. The two-stage rotary screen with the dust collector and the foldable roller comprises a bracket, a motor, a coupling, a screen shaft, a screen body, a supporting frame, the dust collector and the foldable rollers; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen part and a second screen part; the meshes of the first screen part are smaller than those of the second screen part; the dust collector is arranged in the same direction as a waste opening; the foldable rollers are arranged at four corners of the bracket and are movably connected with the bracket. The two-stage rotary screen with the dust collector and the foldable roller has the advantages that the circumstance that the meshes are blocked can be prevented, operators can be protected well, and thus the safety and flexibility in use of the rotary screen can be improved.

Owner:弭勇捷

Two-stage drum screen with protecting cover and moving rolling wheels

InactiveCN104289415AEasy to moveImprove the quality of workSievingScreeningAgricultural engineeringElectric machinery

The invention relates to a chemical fertilizer production device, in particular to a two-stage drum screen with a protecting cover and moving rolling wheels. The two-stage drum screen comprises a support, a motor, a coupler, a screen shaft, a screen body, supporting frames, the protecting cover and the moving rolling wheels, wherein the motor is arranged on the support, the two ends of the screen shaft are connected with the support through bearings, the screen body is connected with the screen shaft through the supporting frames, the motor is connected with the screen shaft through the coupler, the screen body comprises a first screen mesh part and a second screen mesh part with the mesh openings larger than the mesh openings of the first screen mesh part, one side of the protecting cover is fixedly connected with the support, the other side of the protecting cover is detachably connected with the support, and the moving rolling wheels are arranged at the four corners of the support and fixedly connected with the support. According to the two-stage drum screen with the protecting cover and the moving rolling wheels, the work quality and efficiency and the use flexibility and safety of the drum screen are improved.

Owner:崔海花

Two-stage rotary screen with firm support and movable roller

InactiveCN104646273AEasy to moveImprove stabilitySievingScreeningAgricultural engineeringStructural engineering

The invention relates to a chemical fertilizer production device, and in particular relates to a two-stage rotary screen with a firm support and a movable roller. The two-stage rotary screen with the firm support and the movable roller comprises a bracket, a motor, a coupling, a screen shaft, a screen body, supporting frames and the movable rollers; the motor is arranged on the bracket; two ends of the screen shaft are connected with the bracket through a bearing; the screen body is connected with the screen shaft through the supporting frame; the motor is connected with the screen shaft through the coupling; the screen body comprises a first screen part and a second screen part; the meshes of the first screen part are smaller than those of the second screen part; the supporting frames are arranged every interval of 60 degrees along the screen shaft in the radial shaft and are fixedly connected with the screen shaft by welding; the movable rollers are arranged at four corners of the bracket and are fixedly connected with the bracket. The two-stage rotary screen with the firming supporting frame and two types of screens has the advantages that the circumstance that the meshes are blocked can be prevented, the production cost can be saved, and the production efficiency can be greatly increased.

Owner:弭勇捷

Double-layer screen device for ceramsite screening

PendingCN114713492AAvoid cloggingAvoid mesh cloggingSievingScreeningElectric machineryStructural engineering

The invention discloses a double-layer screening device for ceramsite screening, and belongs to the technical field of ceramsite production equipment.The double-layer screening device comprises a base, a mounting frame is arranged at the upper end of the base, a fixing block is arranged on the side edge of the mounting frame, a first motor is arranged at the upper end of the fixing block, and a double-layer screening assembly is arranged at the upper end of the mounting frame; a vibration assembly is arranged at the lower end of the base; the vibration assembly comprises a vibration box, a crankshaft, a shaft diameter, a first mounting base, a connecting rod, a second motor and a second mounting base, the vibration box is arranged at the lower end of the base, the vibration assembly is arranged and can vibrate the double-layer rotary screen, and therefore the problem that screen holes are blocked by ceramsite during screening is avoided; the stability of the device in the vibration process can be improved, and sponge filling layers are arranged on the two sides of the interior of the vibration box, so that the device can provide buffering force during vibration.

Owner:丹晟实业(上海)有限公司

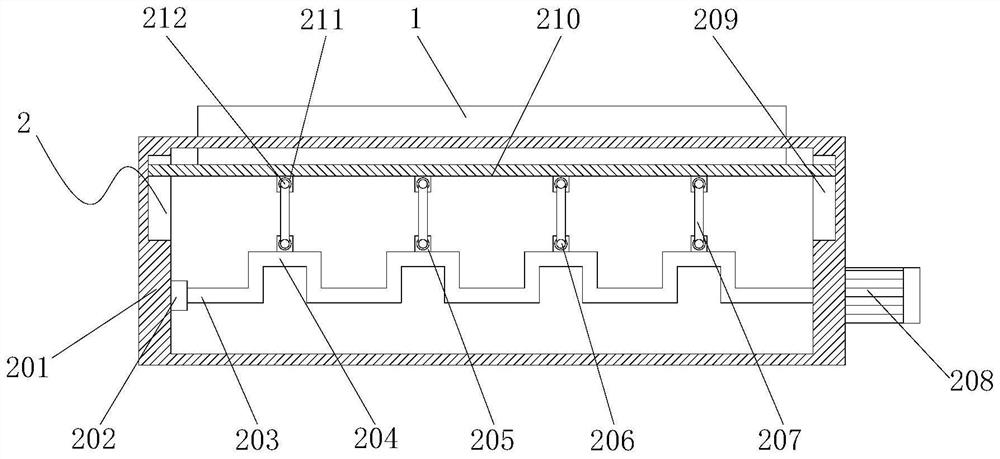

An integrated treatment device for wastewater purification

ActiveCN110204096BGuaranteed water flow throughHigh degree of integrationTreatment involving filtrationMultistage water/sewage treatmentWastewaterWater flow

The invention relates to the field of environmental protection, and specifically discloses an integrated treatment equipment for wastewater purification, including a tank body, a water inlet tank, a partition, a hydraulic expansion mechanism, a fan and a water pump; multiple partitions are fixed in the tank, and the The inside of the tank is divided into a dispersing cylinder, a dosing mixing chamber, a medicament chamber, a filter chamber, and a sewage discharge chamber, and the filter chamber is provided with a first filter screen, a second filter screen, and a third filter screen equidistant from left to right; A horizontal transmission shaft is fixed on the central axis of the first filter, the second filter and the third filter. The end of the transmission shaft goes out of the tank and extends into the transmission box. The impeller is coaxially fixed on the driving gear. , a water outlet pipe is arranged on the left side of the impeller. In the present invention, a plurality of rotatable filter screens are arranged, and the rotation is driven by water flow, so that the filter screen can rotate while reducing energy consumption, so that the filtered area is uniform, and the situation of blocking the mesh holes or being unusable is avoided. .

Owner:山东中望恒力环境技术有限公司

Drum screen with foldable rolling wheels and two kinds of screen meshes

InactiveCN104289425AEasy to moveImprove the quality of workSievingScreeningIndustrial engineeringSecond screen

The invention relates to a chemical fertilizer production device, in particular to a drum screen with foldable rolling wheels and two kinds of screen meshes. The drum screen comprises a support, a motor, a coupler, a screen shaft, a screen body, supporting frames and the foldable rolling wheels, wherein the motor is arranged on the support, the two ends of the screen shaft are connected with the support through bearings, the screen body is connected with the screen shaft through the supporting frames, the motor is connected with the screen shaft through the coupler, the screen body comprises a first screen mesh part and a second screen mesh part with the mesh openings larger than the mesh openings of the first screen mesh part, and the foldable rolling wheels are arranged at the four corners of the support and movably connected with the support. According to the drum screen with the foldable rolling wheels and the two kinds of screen meshes, the situation that the mesh openings are blocked is prevented; the drum screen can move conveniently as needed through the foldable rolling wheels on the bottom of the drum screen, so that the work quality and efficiency and the use flexibility of the drum screen are improved.

Owner:崔海花

An energy-saving pvc new material processing grinding disc fine crushing device

ActiveCN110154265BImprove crushing effectAvoid situations where crushing is not in placeElectric machineProcess engineering

The invention discloses an energy-saving grinding disc fine crushing device for processing new PVC materials, which comprises a base, a crushing box, a material distributing device, a driving motor and a screening tank. The upper part of the inside of the crushing box is provided with a preliminary crushing cavity, and the inside of the crushing box is also horizontally welded with a limit slide bar, and a screening groove is slidably installed on the limit slide bar. The new PVC material is fed at intervals, so that the new PVC material is crushed to avoid blockage caused by too much feeding at one time, which greatly improves the crushing effect, and the sieving tank moves left and right during the screening to speed up the powder of the new PVC material. The screening speed in the screening tank avoids the situation that PVC new material powder clogs the mesh. At the same time, the driving motor drives the crushing and screening at the same time, thereby greatly saving the utilization rate of the motor, and at the same time plays a role in saving energy, energy saving and environmental protection.

Owner:黄山市瑞亿新材料有限公司

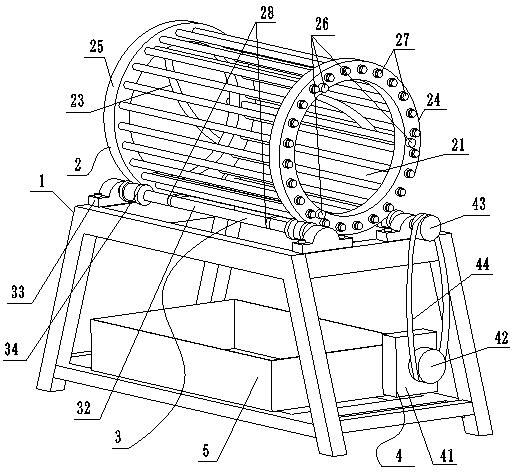

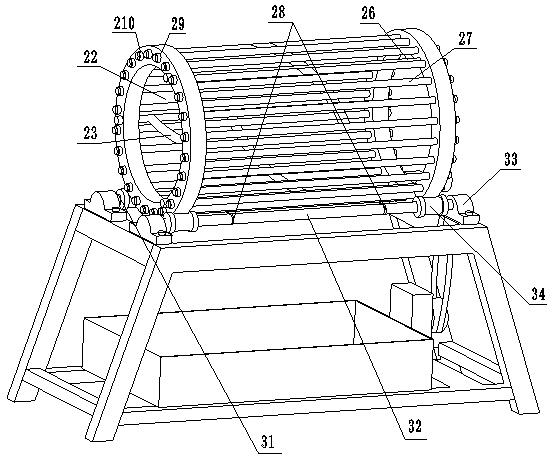

Fresh tea leaf screening device and using method thereof

InactiveCN112642692ARealize hierarchical screeningAvoid mesh cloggingSievingScreeningAgricultural engineeringMechanical engineering

The invention discloses a fresh tea leaf screening device and a using method thereof. The screening device comprises a rack, a screening mechanism, a supporting wheel set, a power mechanism and a receiving hopper. The screening mechanism is arranged on the rack, the supporting wheel set used for supporting the screening mechanism to rotate is arranged on the rack, the power mechanism is arranged on the rack used for providing rotating power for the screening mechanism through the supporting wheel set, a feeding port is formed in one end of the screening mechanism, a discharging port is formed in the other end of the screening mechanism, a material guiding plate is further arranged in the screening mechanism, and the receiving hopper is arranged in the rack and located under the screening mechanism. The screening device is adopted to be used for screening fresh tea leaves, the problem that screen holes are blocked by tea leaves in the screening process can be avoided, damage to fresh leaves in the screening process is reduced, screening is more thorough, and therefore the screening efficiency is improved, automatic operation is achieved, the large-scale processing requirement of tea leaves is met, practicability is high, screened tea leaves can meet subsequent processing, and the quality of tea leaves can be improved easily.

Owner:安顺市晶英科技研发有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com