Wet-laid spunlace anti-stick fiber spunlace steel wire mesh

A steel mesh and spunlace technology, used in needle punching machines, textiles and papermaking, non-woven fabrics, etc., can solve the problems of non-smooth stainless steel wire, reduce the water permeability of the fiber web, and fiber loss, so as to ensure quality and stability. Effects of Sex and Continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

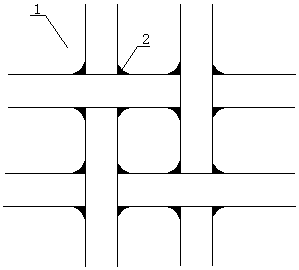

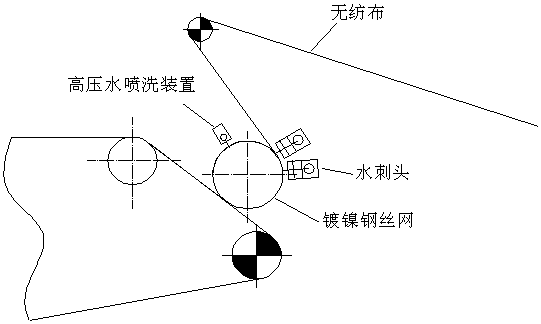

[0010] Embodiment 1: with reference to attached Figure 1-3 . A wet-process spunlace anti-stick fiber spunlace steel wire mesh, the anti-stick fiber spunlace steel wire mesh is a 50-130 mesh single-layer stainless steel wire mesh 1 and the surface of the stainless steel wire mesh 1 has a nickel-plated layer (not shown), nickel-plated In the final 50-130 mesh stainless steel wire mesh, the angle 2 between the upper and lower layers where the warp and weft steel wires interweave is filled with nickel, and the angle is smooth. It is beneficial for the fibers lost under the action of spunlace to be more easily sucked away by vacuum suction, instead of accumulating on the wire mesh. The 50-130 mesh nickel-plated stainless steel wire mesh can make the stagnant The fibers on the wire mesh are smoothly transferred to the water treatment system to solve the problem of fiber accumulation on the wire mesh, thereby ensuring the stability and continuity of production.

[0011] The embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com