Double-layer screen device for ceramsite screening

A double-layer sieve and sieving technology, which is applied in sieves, solid separation, ceramic material production, etc., can solve the problems of clogging of sieving meshes, poor ceramsite sieving effect, and unsatisfactory sieving effect. Improved stability, improved screening output, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

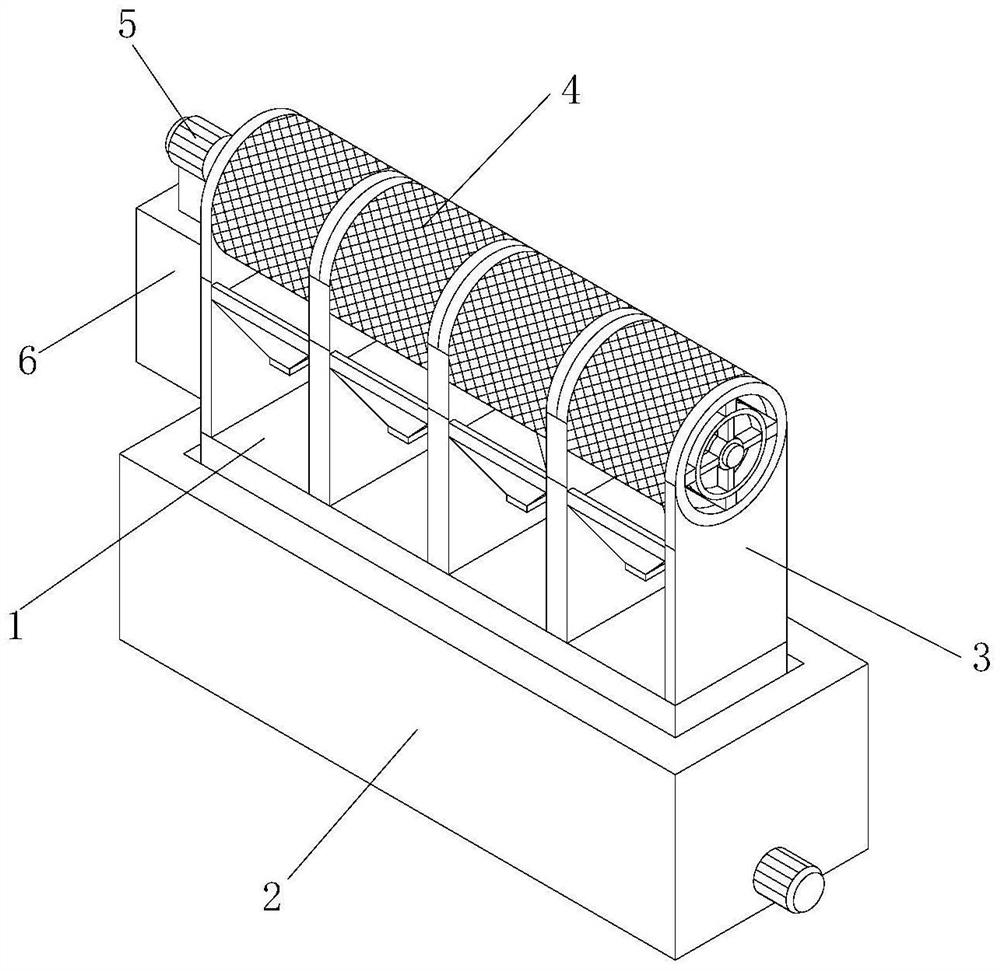

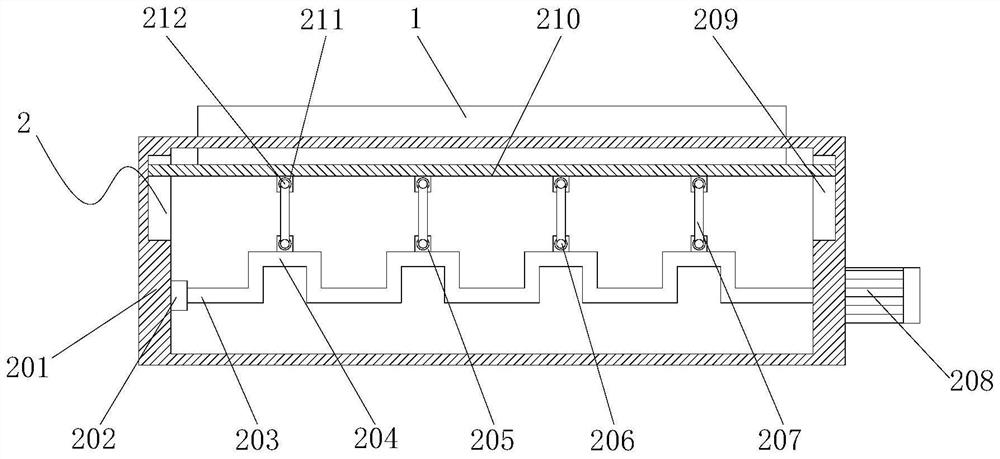

[0024] see Figure 1-4 , the present invention provides the following technical solutions: a double-layer sieve device for ceramsite screening, comprising a base 1, the upper end of the base 1 is provided with a mounting frame 3, the side of the mounting frame 3 is provided with a fixing block 6, the fixing block The upper end of 6 is provided with a motor 5, the upper end of the mounting frame 3 is provided with a double-layer screening component 4, and the lower end of the base 1 is provided with a vibration component 2; the vibration component 2 includes a vibration box 201, a crankshaft 203, a shaft diameter 204, and a mounting seat One 205, the connecting rod 207, the second motor 208 and the second mounting seat 211, wherein the lower end of the base 1 is provided with a vibration box 201, the side of the vibration box 201 is provided with a second motor 208, and the side of the second motor 208 is located in the vibration box 201 A crankshaft 203 is provided inside, the...

Embodiment 2

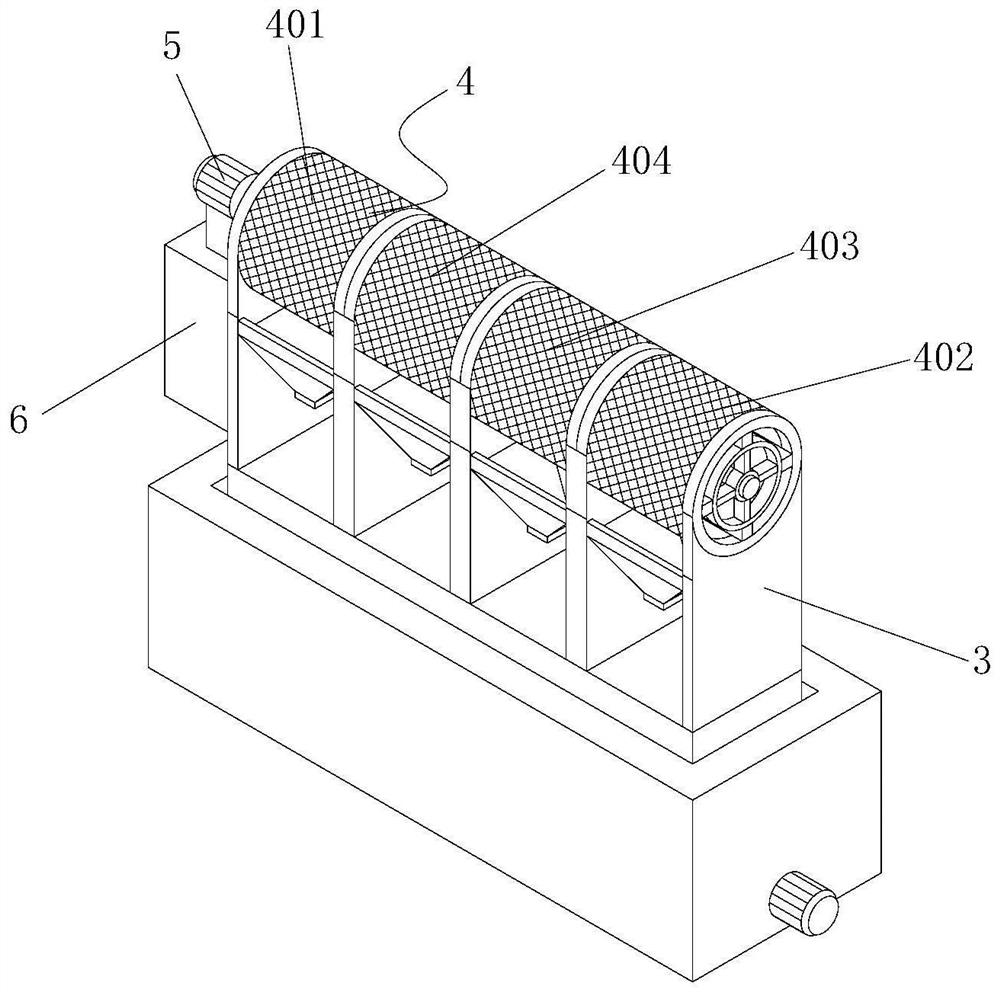

[0035] The difference between this embodiment and Embodiment 1 is that the double-layer screening assembly 4 includes an outer cylinder 401, an outer cylinder 2 402, an outer cylinder 3 403, an outer cylinder 4 404, a connecting block 405, a rotating rod 408, an inner cylinder 409 and screening holes 410, wherein the upper edge of the mounting frame 3 is provided with an outer cylinder 401, the side of the outer cylinder 401 is provided with an outer cylinder 404, and the side of the outer cylinder 404 is provided with an outer cylinder 3 403 , the side of the outer cylinder 3 403 is provided with the outer cylinder 2 402, the inner cylinder 402 is provided with an inner cylinder 409, the surface of the inner cylinder 409 is provided with a screening hole 410, and the side of the inner cylinder 409 is connected with the connection block 405 through the connection block 405. The outer cylinder 402 is fixedly connected, and the side of the motor 1 5 is located inside the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com