Two-stage rotary screen with firm support and movable roller

A technology of moving rollers and trommel screens, which is applied in the fields of filter screens, solid separation, chemical instruments and methods, etc., can solve the problems of impact, reduction of production efficiency, and consumption of manpower and material resources, so as to increase firmness, improve production efficiency, and save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings.

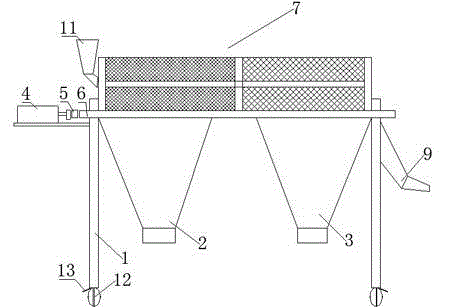

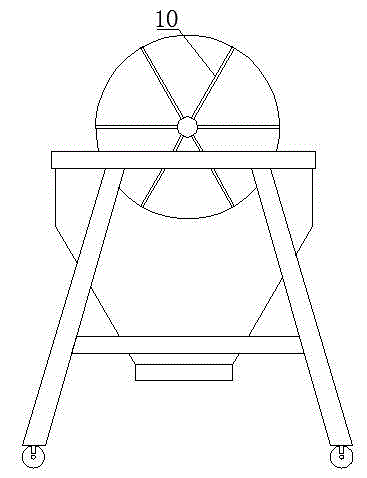

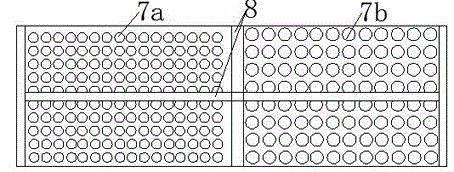

[0017] Such as figure 1 , 2 , 3, start the drum screen, the material enters the screen body 7 from the feed port 11, the motor 4 drives the screen shaft 6 to move through the coupling 5, the rotation of the screen shaft 6 drives the support frame 10 to rotate, and the rotation of the support frame 10 The sieve body 7 is driven to rotate, and the material enters the sieve body 7 and first passes through the first screen part 7a. At this time, the relatively small particles and the crushed waste are screened out and discharged from the first outlet, and the fertilizer then passes through the second sieve. The second sieve part 7b, because the size of the mesh of the second sieve part 7b is equal to the size of the finished fertilizer particles, when the fertilizer passes through the sieve, the fertilizer with the size of the finished particles will be screened out and disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com