Screen-clogging-resisting silk-screen printing screen and preparing method thereof

A technology of mesh screen and screen, which is applied in the field of anti-blocking screen printing screen printing and its preparation, which can solve the problems affecting the quality and efficiency of paint screen printing, back-sticking of printing paint, easy skinning, etc., and achieve waterproof And ideal anti-adhesion performance, reduced friction, low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

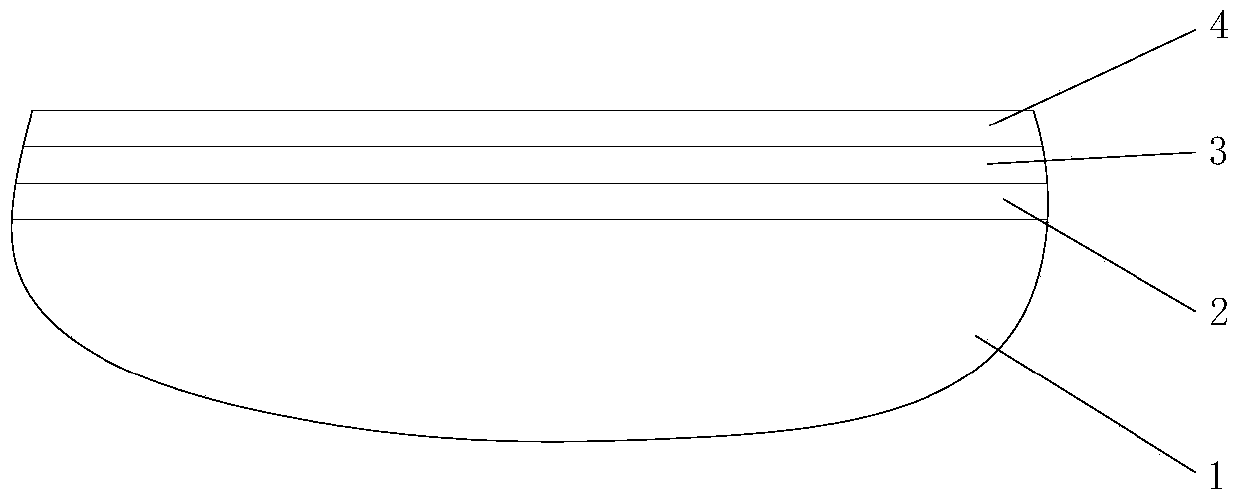

[0024] Embodiment 1, the screen preparation method of the present invention comprises the following steps:

[0025] 1) Clean the substrate with a washing machine;

[0026] 2) Inner layer: the substrate is sent into the coating chamber, and the titanium-aluminum layer is sputtered by radio frequency magnetron. The temperature of the substrate is 25°C, the negative bias voltage is 100V, the working pressure is 0.2Pa, the substrate speed is 2rpm, and the current of the titanium target and the aluminum target is 4A. , the CH4 flow rate is 10 sccm, the argon gas flow rate is 50 sccm, the sputtering time is 30 min, the radio frequency power is 100 W, the titanium target, the distance between the aluminum target and the substrate is 30 mm;

[0027] 3) The first layer of the middle layer: continue to radio frequency magnetron sputtering 70wt% titanium aluminum + 30wt% diamond-like carbon layer, the temperature of the substrate is 25 ℃, the negative bias voltage is 100V, the working pr...

Embodiment 2

[0030] Embodiment 2, the screen preparation method of the present invention comprises the following steps:

[0031] 1) Clean the substrate with a washing machine;

[0032] 2) Inner layer: send the substrate into the coating chamber, radio frequency magnetron sputtering titanium aluminum layer, the temperature of the substrate is 45°C, the negative bias voltage is 130V, the working pressure is 0.6Pa, the substrate speed is 6rpm, the current of titanium target and aluminum target is 5A , the CH4 flow rate is 17 sccm, the argon gas flow rate is 75 sccm, the sputtering time is 60 min, the radio frequency power is 150 W, the titanium target, the distance between the aluminum target and the substrate is 45 mm;

[0033] 3) The first layer of the middle layer: continue radio frequency magnetron sputtering 70wt% titanium aluminum + 30wt% diamond-like carbon layer, the temperature of the substrate is 45 ℃, the negative bias voltage is 130V, the working pressure is 0.6Pa, the substrate s...

Embodiment 3

[0036] Embodiment 3, the screen preparation method of the present invention comprises the following steps:

[0037] 1) Clean the substrate with a washing machine;

[0038] 2) Inner layer: send the substrate into the coating chamber, radio frequency magnetron sputtering titanium-aluminum layer, the temperature of the substrate is 60°C, the negative bias voltage is 150V, the working pressure is 1Pa, the substrate speed is 8rpm, the current of the titanium target and the aluminum target is 6A, The flow rate of CH4 is 25sccm, the flow rate of argon gas is 100sccm, the sputtering time is 90min, the RF power is 200W, the distance between titanium target, aluminum target and substrate is 60mm;

[0039]3) The first layer of the middle layer: continue to radio frequency magnetron sputtering 70wt% titanium aluminum + 30wt% diamond-like carbon layer, the temperature of the substrate is 60 ℃, the negative bias voltage is 150V, the working pressure is 1Pa, the substrate speed is 8rpm, tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com