Tray-type three-dimensional fermentation system without turning over and fermentation method thereof

A fermentation system and tray-type technology, applied in the field of tray-free three-dimensional fermentation system, can solve the problems of material spillage polluting the environment, easy blockage of the fermentation system, poor operation stability, etc., to achieve smooth outer surface, ensure high efficiency and operation stability. , the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

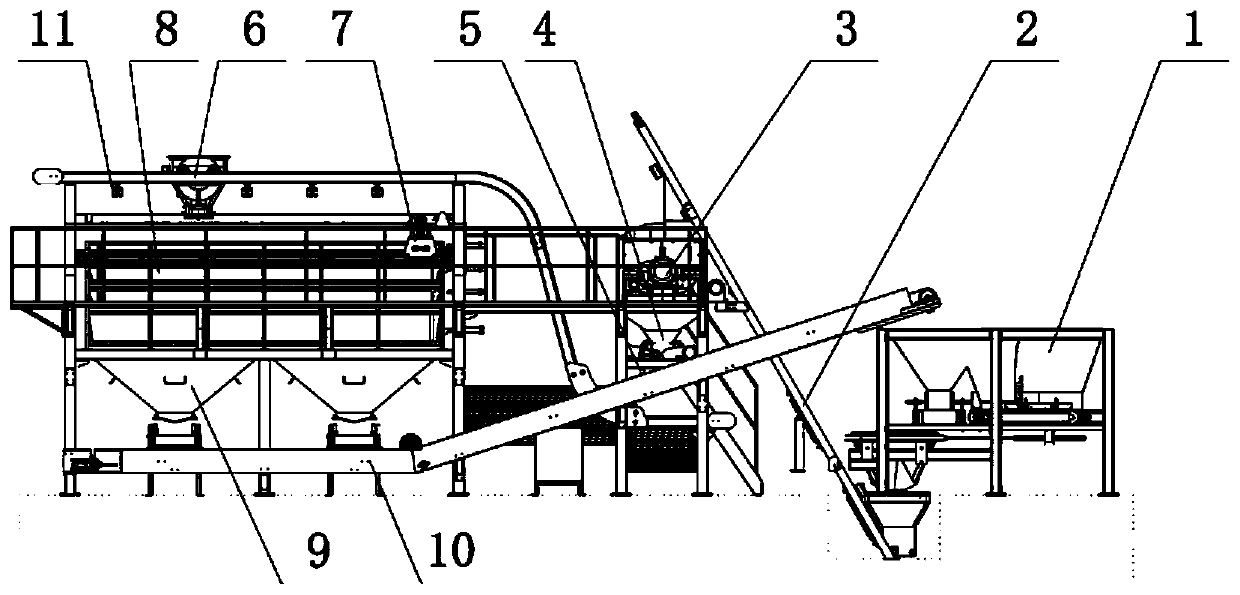

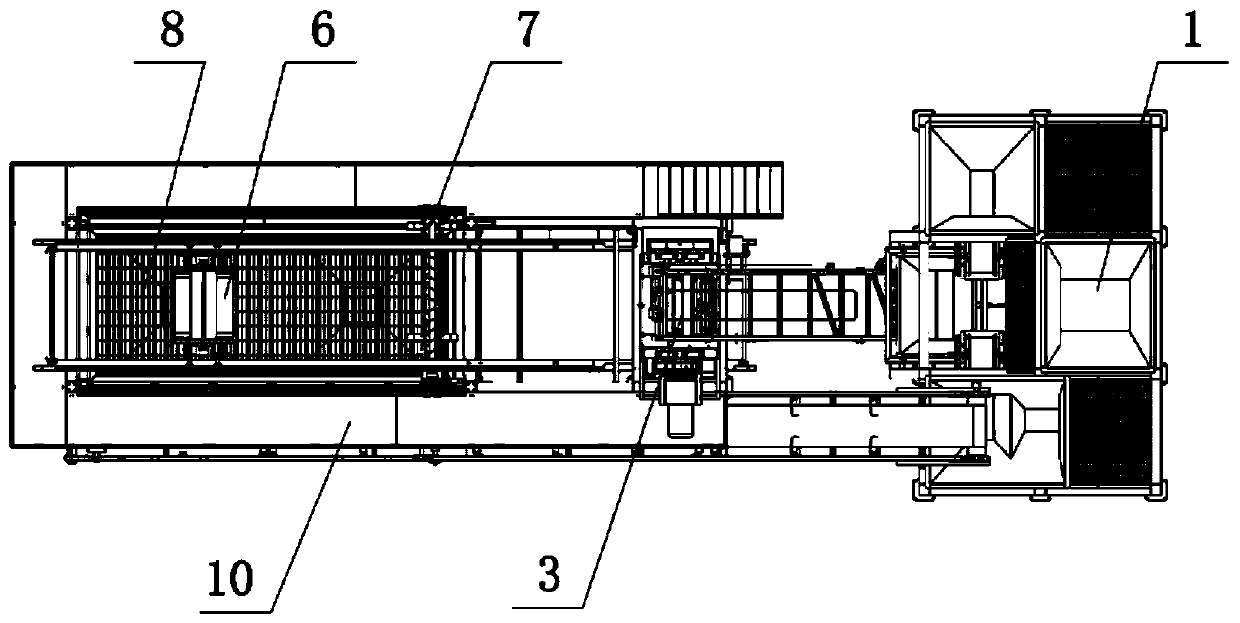

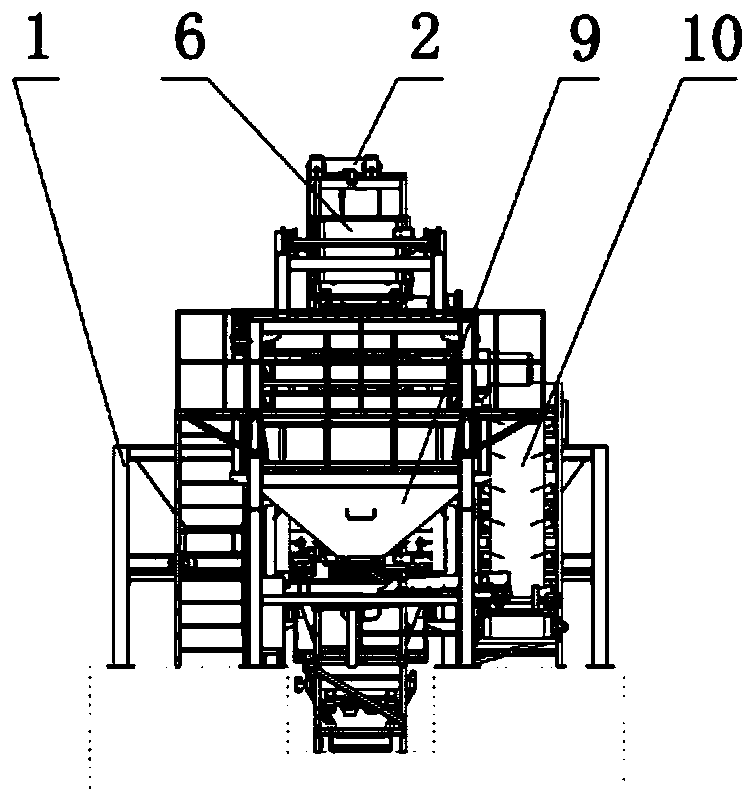

[0079] see Figure 1 to Figure 11 As shown, the present invention provides a tray-free three-dimensional fermentation system, which includes a material lifting device 6 and a fermentation tray 8, wherein the fermentation trays 8 are three-dimensionally stacked and installed, and the lifting and distributing integrated machine 6 is installed on the bottom of the fermentation tray 8 On one side, the lifting distribution hopper 62 is located above the top fermentation tray 8; the fermentation tray 8 is provided with a side frame 81, a rotatable bottom plate 82, a bottom plate linkage mechanism 83 and a bottom plate driving mechanism 84, and the rotatable bottom plate 82 passes through the The bottom plate linkage mechanism 83 is in transmission connection with the bottom plate driving mechanism 84, and the rotatable bottom plate 82, the bottom plate linkage mechanism 83 and the bottom plate driving mechanism 84 are installed on the side frame 81 of the disk; wherein the organic ma...

Embodiment 2

[0121] This embodiment is basically the same as Embodiment 1, the difference is:

[0122] In the tray-type three-dimensional fermentation system without overturning, the support frame 823 is welded by 6 pieces of flat steel in the radial direction and 20 pieces of flat steel in the axial direction, and the lower edges of the two pieces on both sides are inclined inward; The bottom net 824 is a metal woven wire net, and is installed on the upper surface of the support frame 823 by riveting.

[0123] The inclination angle between the inner support surface of the side network inclined support 8112 and the horizontal plane of the bottom of the pan is 85°.

[0124] The height of the disc side frame 81 is 600 mm, and the aperture diameter of the side net 812 and the disc bottom net 824 is 10 mm.

[0125] Among the various layers of fermentation trays 8, the height of the first to third layers is 300mm, and the height of the fourth layer is 2.5 times, that is, a height of 750mm, so ...

Embodiment 3

[0129] This embodiment is basically the same as Embodiment 1, the difference is:

[0130] In the tray-type three-dimensional fermentation system without overturning, the support frame 823 is welded by 4 pieces of flat steel in the radial direction and 10 pieces of flat steel in the axial direction, and the lower edges of the two pieces on both sides are inclined inward; The bottom net 824 is a metal woven wire net, and is installed on the upper surface of the support frame 823 by riveting.

[0131] The inclination angle between the inner support surface of the side net inclined support 8112 and the horizontal plane of the bottom of the pan is 75°.

[0132] The height of the disc side frame 81 is 350 mm, and the aperture diameter of the side net 812 and the disc bottom net 824 is 6 mm.

[0133] Among the various layers of fermentation trays 8, the height of the first to third layers is 300mm, and the height of the fourth layer is twice that of 600mm, so that the fermented mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com