Caking zinc sulfate scattering device and using method thereof

A technology of zinc sulfate and agglomeration, applied in chemical instruments and methods, solid separation, filter screen, etc., can solve problems such as inability to clean up, filter screen hole blockage, etc., and achieve the effect of avoiding mesh hole blockage, avoiding blockage, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

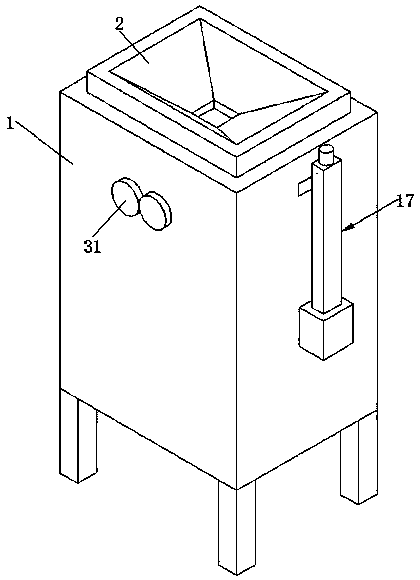

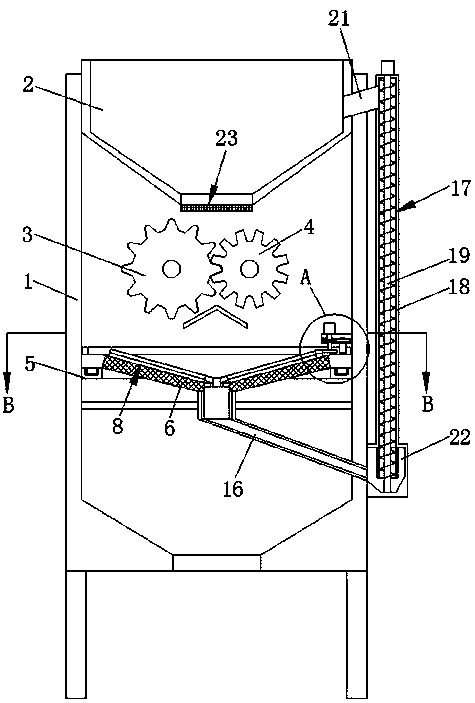

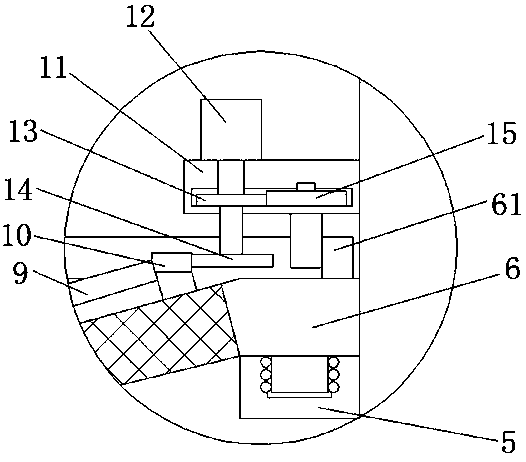

[0024] The present invention provides such Figure 1-6 A kind of agglomerated zinc sulfate disintegration device shown, comprises box body 1, collecting funnel 2, screening net 6, cleaning device 8 and conveying device 17, and described box body 1 interior is hollow, and a group of Collecting funnel 2, a limited material valve 23 is installed at the bottom of the collecting funnel 2, a first crushing roller 3 and a second crushing roller 4 are arranged symmetrically directly below the collecting funnel 2, and the first crushing roller 3 An inverted V-shaped baffle plate is fixed directly below the second crushing roller 4, and an installation ring 5 is fixed on the inner wall of the box body 1 below the material baffle plate, and a screening net 6 is installed on the installation ring 5 for rotation. The top of the installation ring 5 is dug with an arc-shaped cavity, and the bottom of the screening net 6 is fixed with an insertion ring, and the insertion ring is rotatably arr...

Embodiment 2

[0031] The present invention provides such figure 1 , 2 A kind of agglomerated zinc sulfate disintegration device shown, comprises box body 1, collecting funnel 2, screening net 6, cleaning device 8 and conveying device 17, and described box body 1 interior is hollow, and a group of Collecting funnel 2, a limited material valve 23 is installed at the bottom of the collecting funnel 2, a first crushing roller 3 and a second crushing roller 4 are arranged symmetrically directly below the collecting funnel 2, and the first crushing roller 3 An inverted V-shaped baffle plate is fixed directly below the second crushing roller 4, and an installation ring 5 is fixed on the inner wall of the box body 1 below the material baffle plate, and a screening net 6 is installed on the installation ring 5 for rotation. The sieve net 6 is funnel-shaped, and a group of through chambers are provided at the center of the sieve net 6 , and a fixed channel 16 is fixed below the sieve net 6 by a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com