Two-stage rotary screen with dust collector and firm supporting frame

A technology of dust collection device and trommel screen, which is applied in the direction of filtering, solid separation, dust removal, etc. It can solve problems affecting normal production, large dust, and threats to the health of operators, so as to improve safety and stability, reduce Harmful substances, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings.

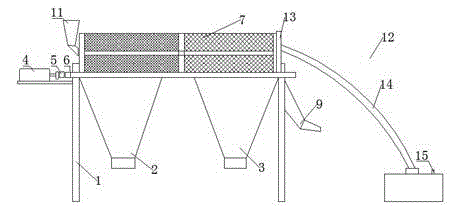

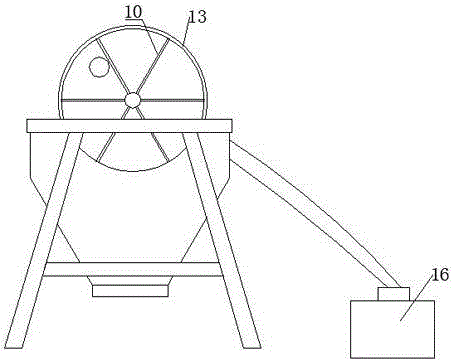

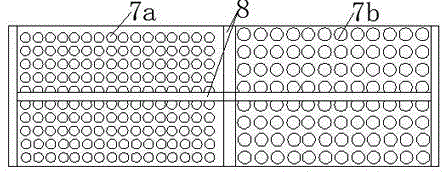

[0017] Such as figure 1 , 2 As shown in , 3, before the drum screen is ready for work, start the dust suction device 12, press the control switch 15, the drive motor 16 starts to run, thereby driving the dust suction pipe 14 to start the drum screen, and the material enters the screen from the feed port 11 In the body 7, the motor 4 drives the screen shaft 6 to move through the coupling 5, the rotation of the screen shaft 6 drives the support frame 10 to rotate, the rotation of the support frame 10 drives the screen body 7 to rotate, and the material enters the screen body 7 and first passes through the first screen The net part 7a, at this time, the relatively small particles and the crushed waste are screened out and discharged from the first discharge port, and the fertilizer then passes through the second screen part 7b, due to the size of the mesh of the second scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com