Double-metal composite plate forming die for manufacturing sliding bearing

A sliding bearing and molding die technology, which is applied in cleaning methods and utensils, cleaning methods using gas flow, removing smoke and dust, etc., can solve the problems of slow molding speed and difficult slag cleaning, achieve fast molding speed and improve work stability. sex, improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

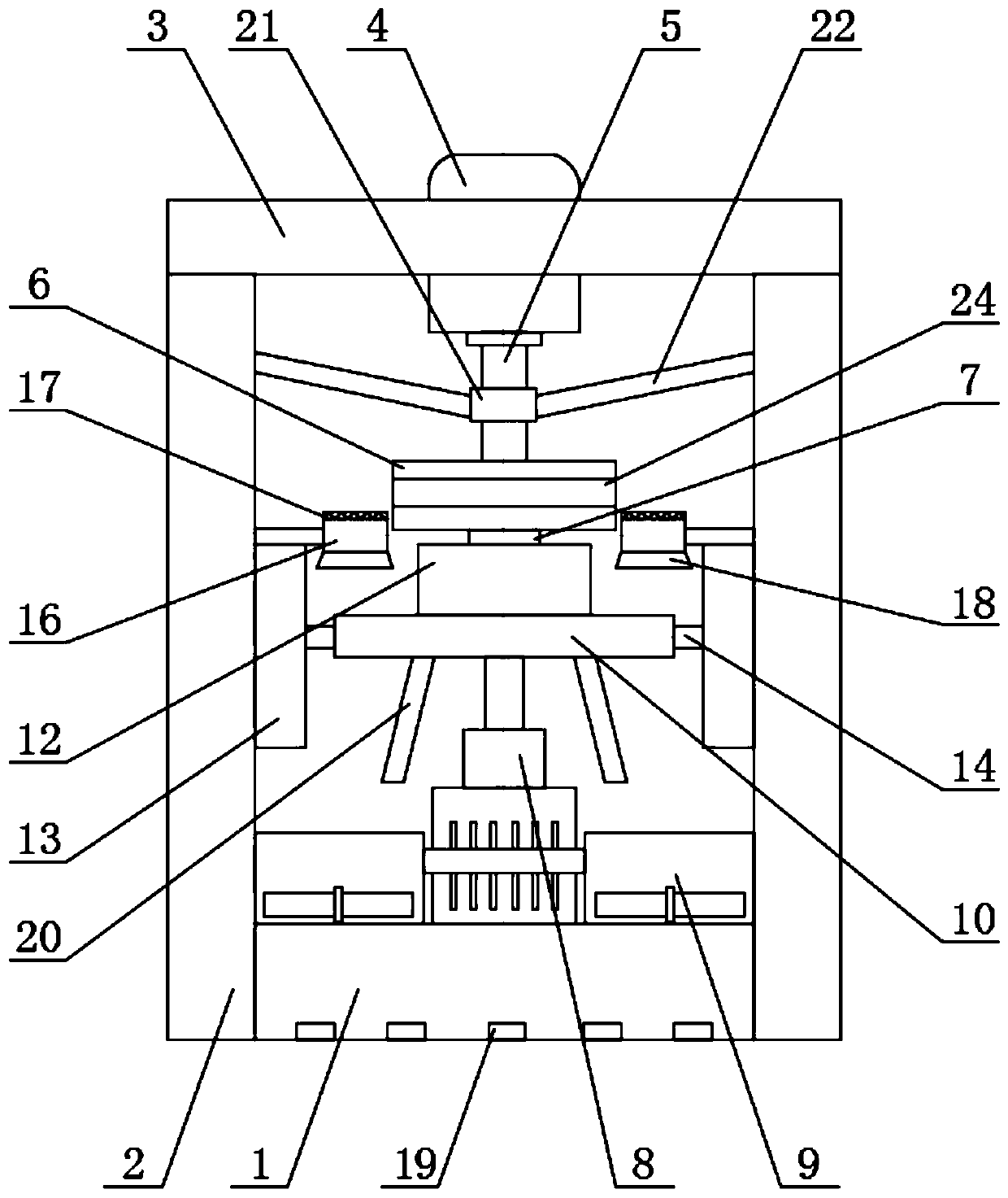

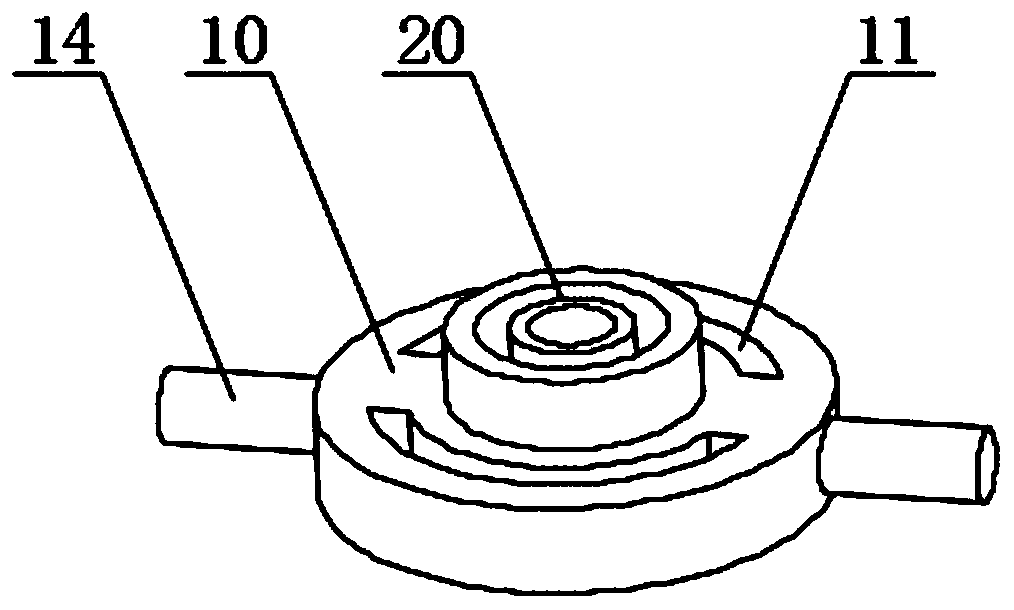

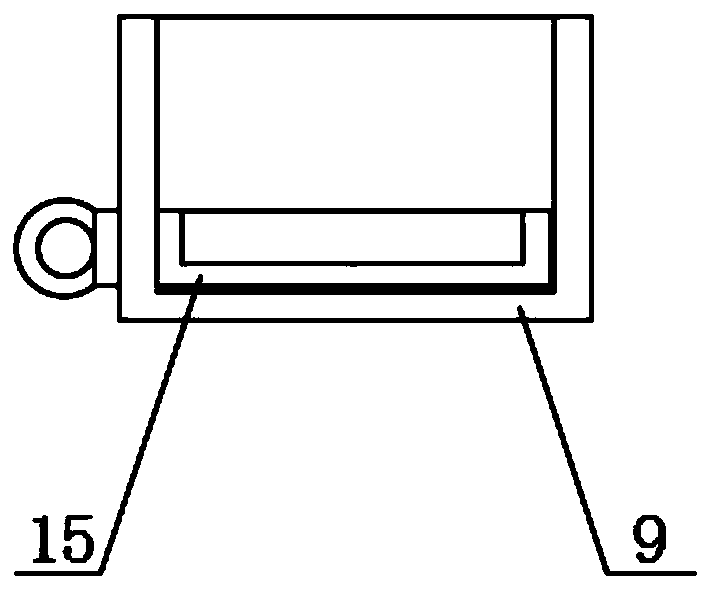

[0021] Such as Figure 1-4 As shown, the present invention provides a technical solution: a bimetallic composite plate molding die for sliding bearing production, comprising a base 1, the bottom surface of the base 1 is provided with an anti-skid groove 19, the depth of the anti-skid groove 19 is two centimeters, by setting the anti-skid The groove 19 can improve the friction strength between the base 1 and the contact surface, and avoid the base 1 from slipping during the working process. The left and right sides of the base 1 are fixedly connected with the first support plate 2, and the top of the first support plate 2 is fixedly connected with a The second support plate 3, the bottom surface of the second support plate 3 is fixedly inlaid with a geared motor 4, the model of the geared motor 4 is ZH-400-60-S, the output end of the geared motor 4 is fixedly connected with a rotating rod 5, and the rotating rod 5 The outer surface of the outer surface is provided with a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com