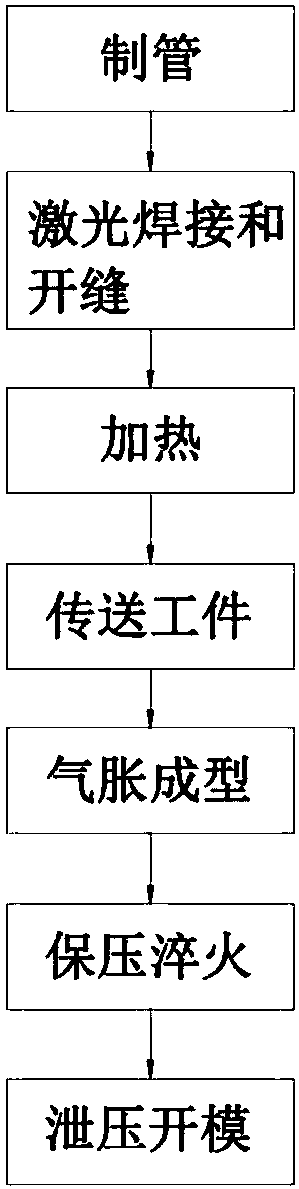

Open pipe air-expansion thermoforming mold and process

A technology for thermoforming and pipe fittings, which is applied in the field of open pipe fittings inflatable thermoforming molds and processes, pipe fittings inflatable thermoforming molds and processes, to achieve the effects of convenient and quick operation, solving difficult sealing, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

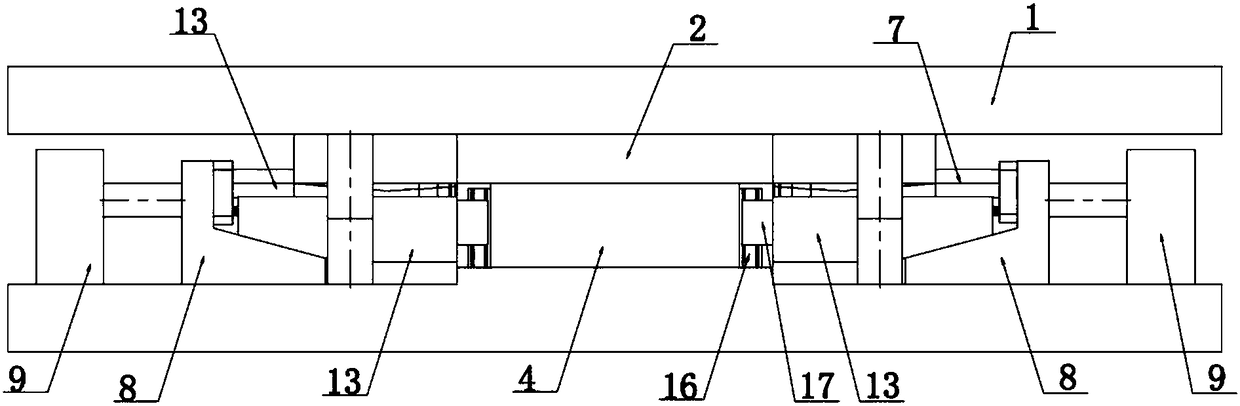

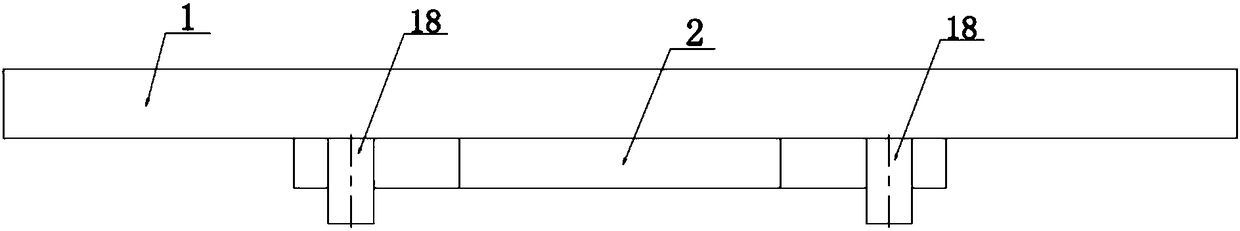

[0047] like Figure 2-9 As shown, a kind of open pipe fittings air expansion thermoforming mold comprises an upper mold assembly and a lower mold assembly, and the upper mold assembly includes an upper template 1 and an upper mold base 2 arranged on the lower surface of the upper template. The lower mold assembly includes a lower template 3 and a lower mold base 4 arranged on the upper surface of the lower template. The surfaces of the upper and lower mold bases are respectively provided with an upper molding surface 5 and a lower molding surface 6 that are compatible with the open molding pipe fittings. , the mold cavity is formed after the upper mold base and the lower mold base are molded together, and the pipe end positioning and sealing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com