A plywood heating and shaping device

A heat-setting and plywood technology, which is applied to wood processing appliances, wood veneer bonding, and manufacturing tools, etc., can solve problems such as low production efficiency, long time-consuming plywood, and inability of heavy objects to move, so as to reduce operation steps and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

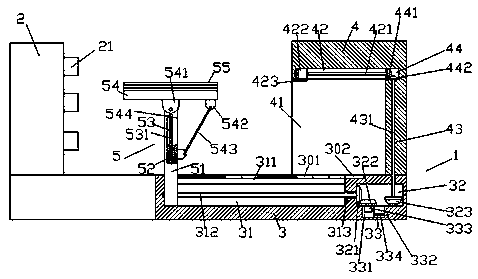

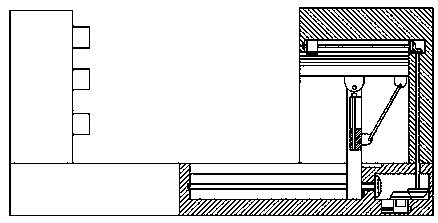

[0019] Such as figure 1 and image 3 As shown, a plywood heating and shaping device of the present invention includes a frame body 3, a heating part 2 is arranged on the upper left side of the frame body 3, and a plurality of sets of heaters 21 are arranged on the upper and lower sides of the right end surface of the heating part 2, The heater 21 is used to heat the pressed plywood, the upper right side of the frame body 3 is provided with a pressure applying part 4, and the frame body between the pressure applying part 4 and the heating part 2 3 is provided with a control part 5, the inside of the right side of the frame body 3 is provided with a first sliding groove 31, and the top of the first sliding groove 31 is provided with an empty groove extending along the first sliding groove 31 311, the frame body 3 on the right side of the first sliding groove 31 is provided with a first transmission groove 32, and the first sliding groove 31 is provided with a first spiral rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com