Water-saving heating reaction kettle for laboratory

A technology for heating reaction kettles and laboratories, applied in the field of reaction kettles, can solve the problems of uneven heating of reaction kettles, poor water saving and energy saving effects, and different jacket temperatures, and achieves a stable and heat-reducing solution that is easy to move and stop. The effect of running off and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

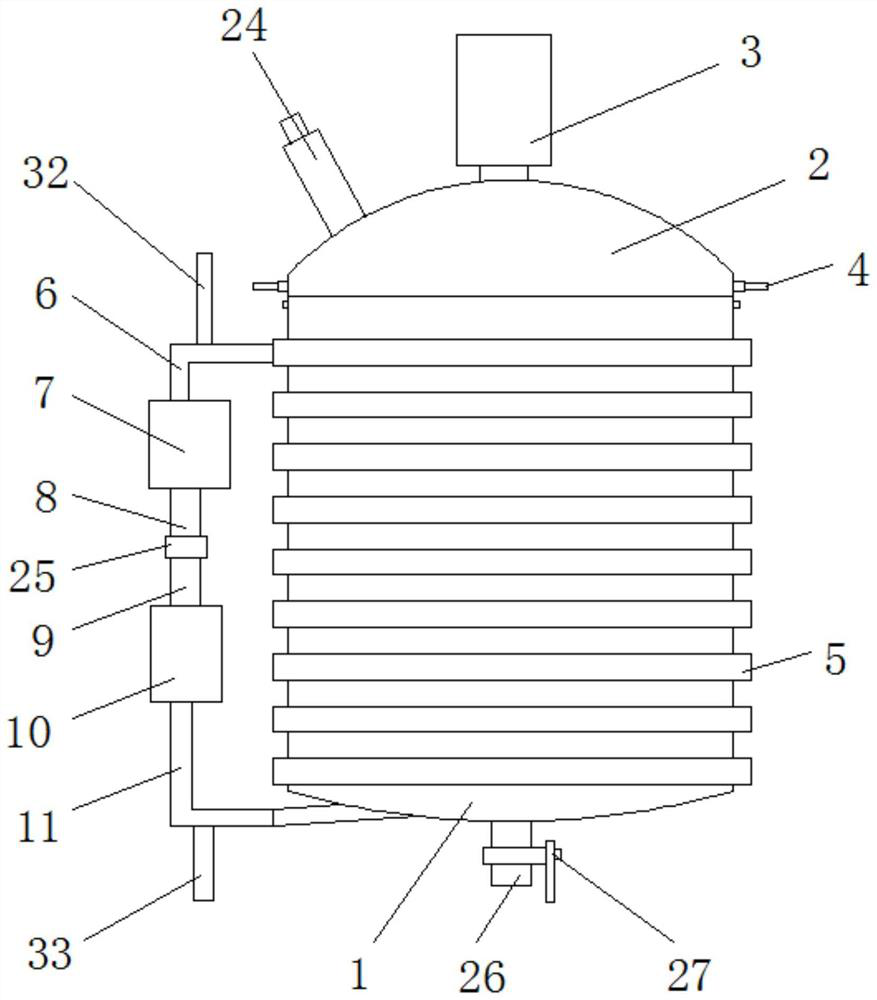

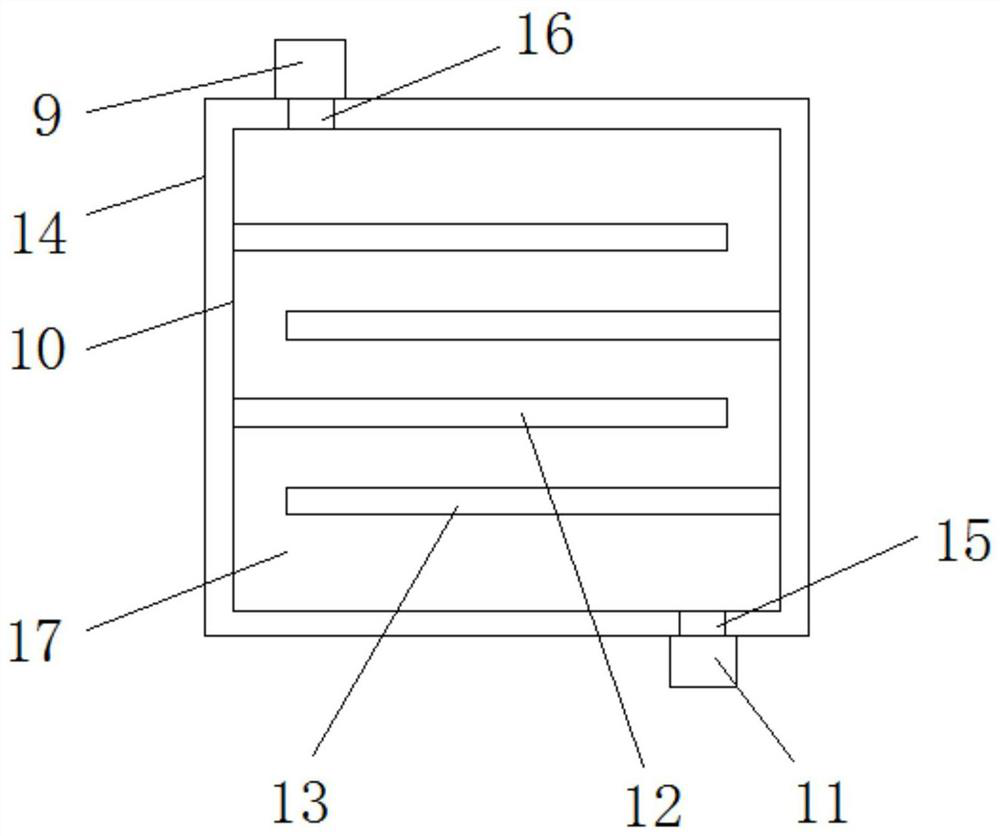

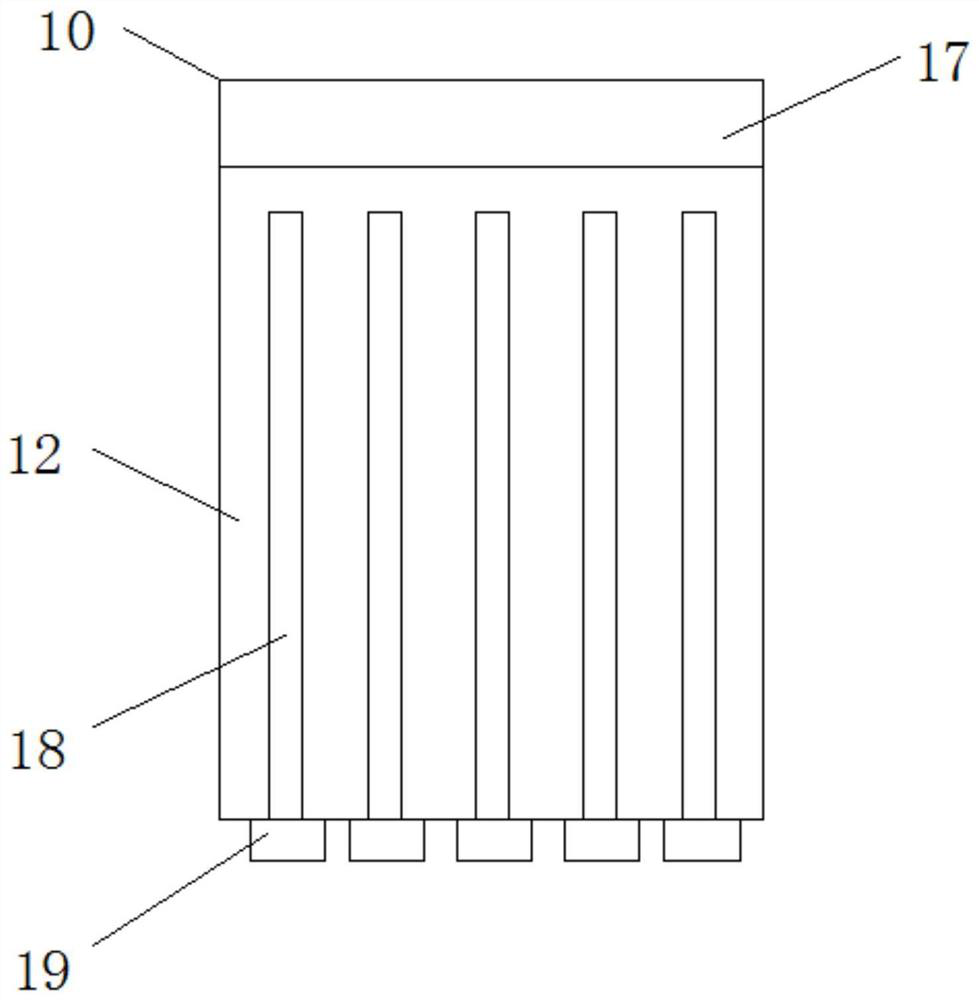

[0027] refer to Figure 1-4 , a laboratory water-saving heating reactor, including a reactor body 1, the upper surface of the reactor body 1 is provided with a sealing cover 2, the upper surface of the sealing cover 2 is fixedly installed with a stirring motor 3 and a feeding pipe 24, sealed Both ends of the cover 2 are movably hinged with a lock 4, the outer surface of the reactor body 1 is fixedly sleeved with a heating sleeve 5, the top end of the heating sleeve 5 is fixedly connected to a water inlet pipe 6, and the lower end of the water inlet pipe 6 is fixedly connected to There is a circulating water pump 7, the lower end of the circulating water pump 7 is fixedly connected with a first connecting pipe 8, the lower end of the first connecting pipe 8 is fixedly connected with a second connecting pipe 9, and the lower end of the second connecting pipe 9 is fixedly connected with a constant temperature heating box 10, the constant temperature The lower end of the heating b...

Embodiment 2

[0036] refer to Figure 1-3 and Figure 5, a laboratory water-saving heating reactor, including a reactor body 1, the upper surface of the reactor body 1 is provided with a sealing cover 2, the upper surface of the sealing cover 2 is fixedly installed with a stirring motor 3 and a feeding pipe 24, sealed Both ends of the cover 2 are movably hinged with a lock 4, the outer surface of the reactor body 1 is fixedly sleeved with a heating sleeve 5, the top end of the heating sleeve 5 is fixedly connected to a water inlet pipe 6, and the lower end of the water inlet pipe 6 is fixedly connected to There is a circulating water pump 7, the lower end of the circulating water pump 7 is fixedly connected with a first connecting pipe 8, the lower end of the first connecting pipe 8 is fixedly connected with a second connecting pipe 9, and the lower end of the second connecting pipe 9 is fixedly connected with a constant temperature heating box 10, the constant temperature The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com