Sterilization and dust collection device for luggage production

A technology for dust removal devices and bags, which is applied in the direction of cleaning methods, cleaning methods and utensils using tools, textiles and papermaking, etc., can solve the problems of poor quality, fabric sterilization and low dust removal efficiency, etc. Quality, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

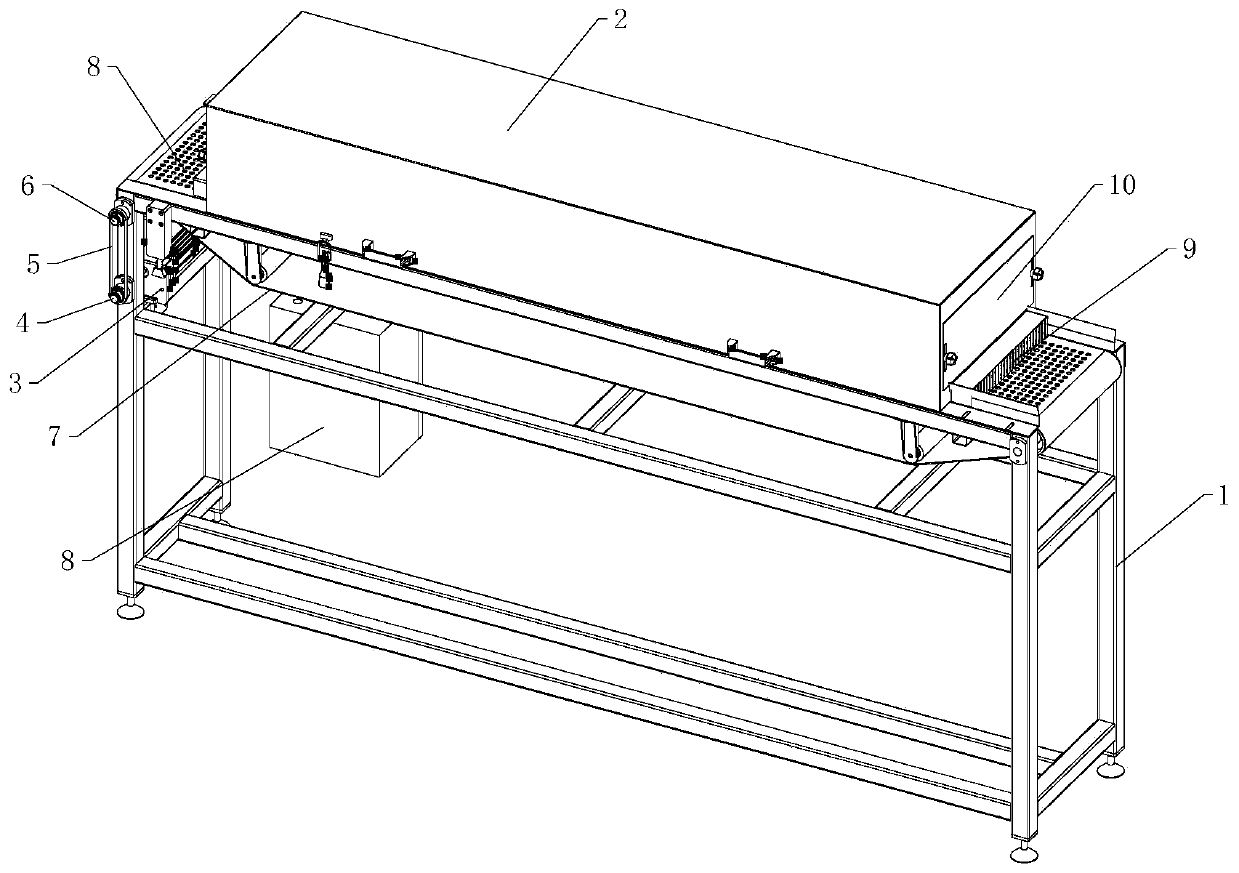

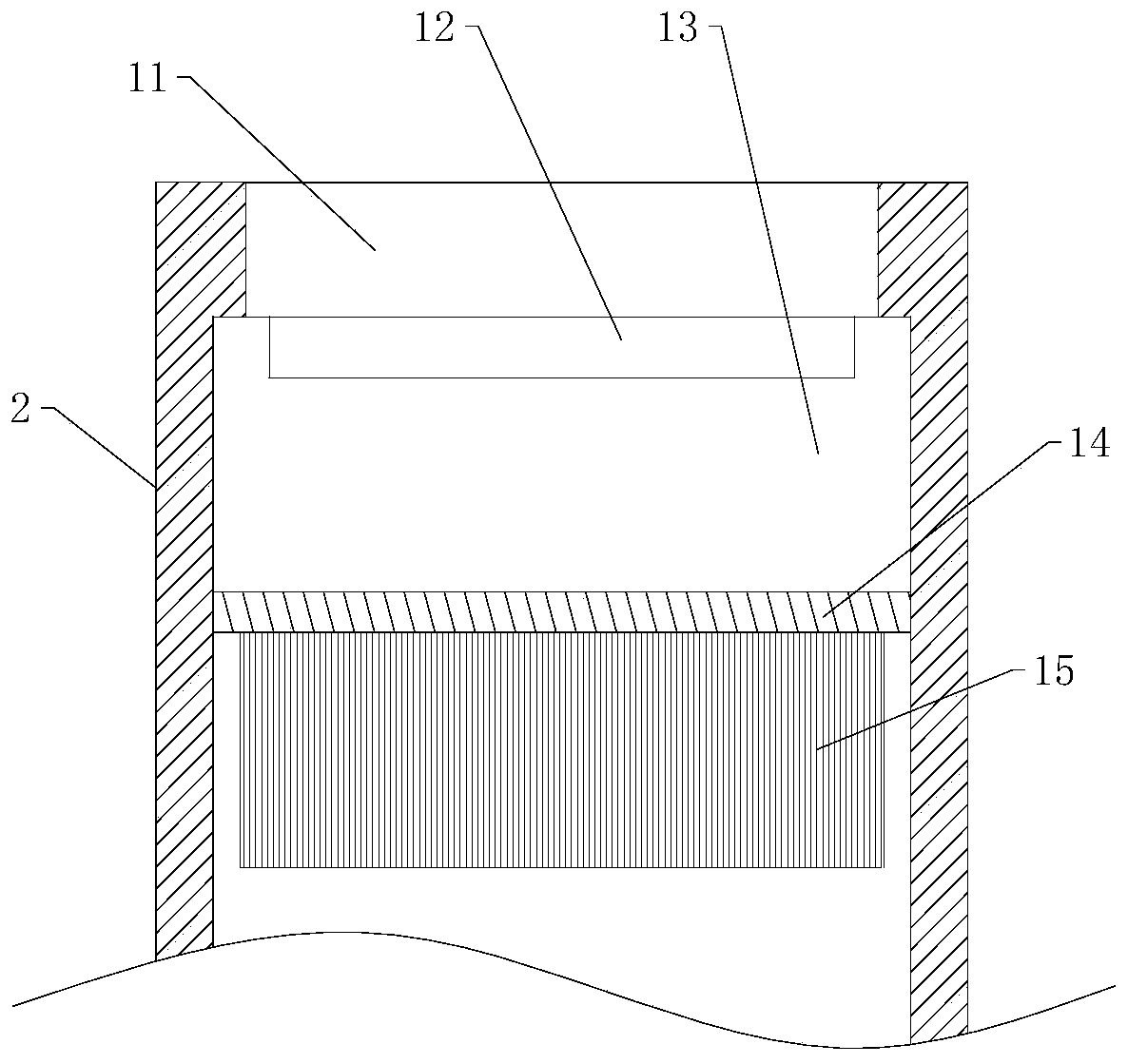

[0030] A sterilizing and dedusting device used in the production of bags, such as Figure 1-2 Shown, comprise main frame 1, processing box 2 is installed on main frame 1, motor 3 is installed on main frame 1, driving wheel 4 is installed on motor 3, driving belt 5 is installed on driving wheel 4, and transmission belt 5 is installed with Driven wheel 6, the driven wheel 6 is sleeved with a conveyor belt 7, the conveyor belt 7 runs through the processing box 2 and is arranged, an electric control box 8 electrically connected with the motor 3 is also installed on the main frame 1, and a storage battery 11 is installed on the top of the processing box 2, An ultraviolet light tube 12 is installed on the storage battery 11 , a processing channel 13 is arranged in the processing box 2 , a brush mounting plate 14 is installed in the processing channel 13 , and a hair brush 9 is installed on the brush mounting plate 14 .

[0031] When this embodiment is in use, the case and bag fabric...

Embodiment 2

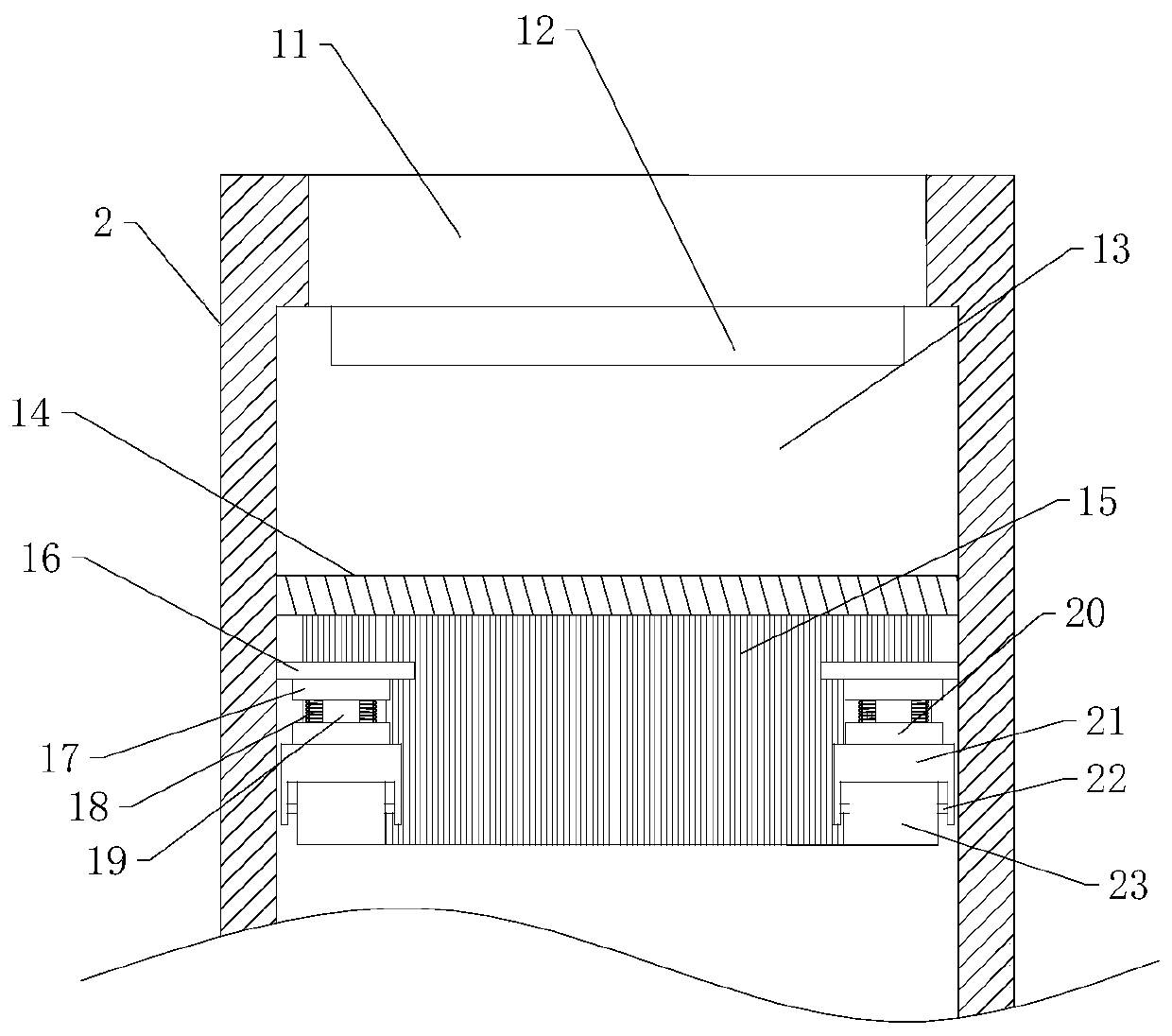

[0033] A sterilizing and dedusting device used in the production of bags, such as image 3 As shown, in order to improve the efficiency and quality of fabric sterilization and dust removal; this embodiment makes the following improvements on the basis of embodiment 1: a first mounting plate 16 is installed in the processing cavity, and the first mounting plate 16 is installed on the side close to the conveyor belt 7. Position wheel mounting seat 21, rotating shaft 22 is installed on the limiting wheel mounting seat 21, and limiting wheel 23 is installed on the rotating shaft 22. By installing the first installation plate 16 in the processing cavity, the first installation plate 16 is equipped with a limit wheel mounting seat 21, and the limit wheel mounting seat 21 is equipped with a limit wheel 23. The limit theory can realize the lifting of the side of the fabric. To limit the guiding role, thereby avoiding the side of the fabric from warping, and further improving the effic...

Embodiment 3

[0037] A sterilizing and dedusting device used in the production of bags, such as Figure 4 As shown, in order to improve the efficiency and quality of bag fabric sterilization; the present embodiment makes the following improvements on the basis of embodiment 1: a second mounting plate 26 is installed on the main frame 1, and the second mounting plate 26 penetrates the processing box 2 and is arranged. A plurality of second air holes 25 are installed on the second mounting plate 26 , and a hot air box 24 is installed on the main frame 1 , and the second air holes 25 communicate with the hot air box 24 . By installing the second mounting plate 26 on the main frame 1, and establishing a plurality of second air holes 25 on the second mounting plate 26, the hot air box 24 is installed on the mounting frame, and the hot air box 24 produces hot air, and then passes through the second air hole 25 output, realize the heat treatment of the fabrics located in the treatment box 2, effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com