Heating tube assembly for water heater

A technology for heating pipes and water heaters, applied in the field of heating pipe assemblies for water heaters, can solve the problems of easy water leakage, poor effect, inconvenient disassembly and installation, etc., and achieve the effects of avoiding leakage, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the following describes the present invention in detail with reference to the accompanying drawings and in combination with the embodiments.

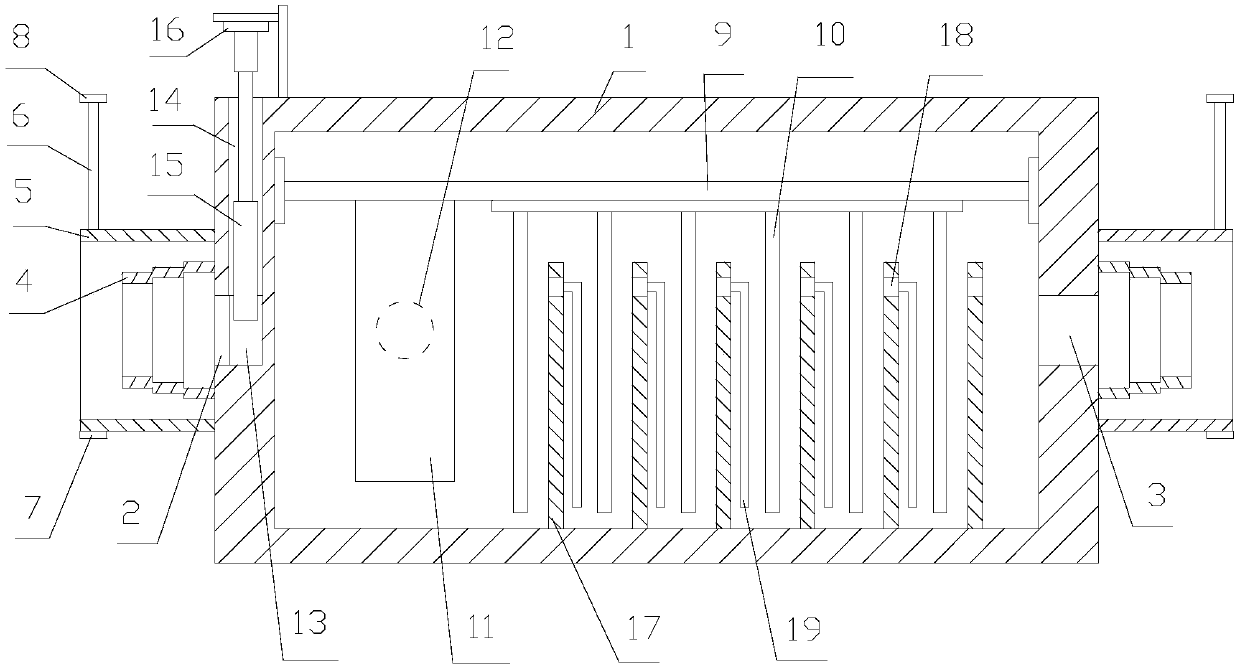

[0017] refer to figure 1 , a heating tube assembly for a water heater proposed by the present invention includes a housing 1, a heating part, a first connecting unit, and a second connecting unit. The housing 1 is provided with a water inlet 2 and a water outlet 3. The heating part is located in the housing 1; the first connecting unit includes a first connecting pipe 4, a first sealing sleeve 5, and a first connecting ring 6, one end of the first connecting pipe 4 is connected to the water inlet 2, and the outer wall of the first connecting pipe 4 is provided with a second An external thread, the outer diameter of the first connecting pipe 4 gradually decreases with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com