Taper-lock external expansion type centering drilling clamp

A technology of drilling jig and expansion sleeve, which is applied in the field of expansion sleeve centering drilling jig, which can solve the problems that the hole position cannot meet the pattern requirements, the position accuracy cannot be guaranteed, and the three-point expansion force is not enough. Easy to popularize and use, light in weight and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

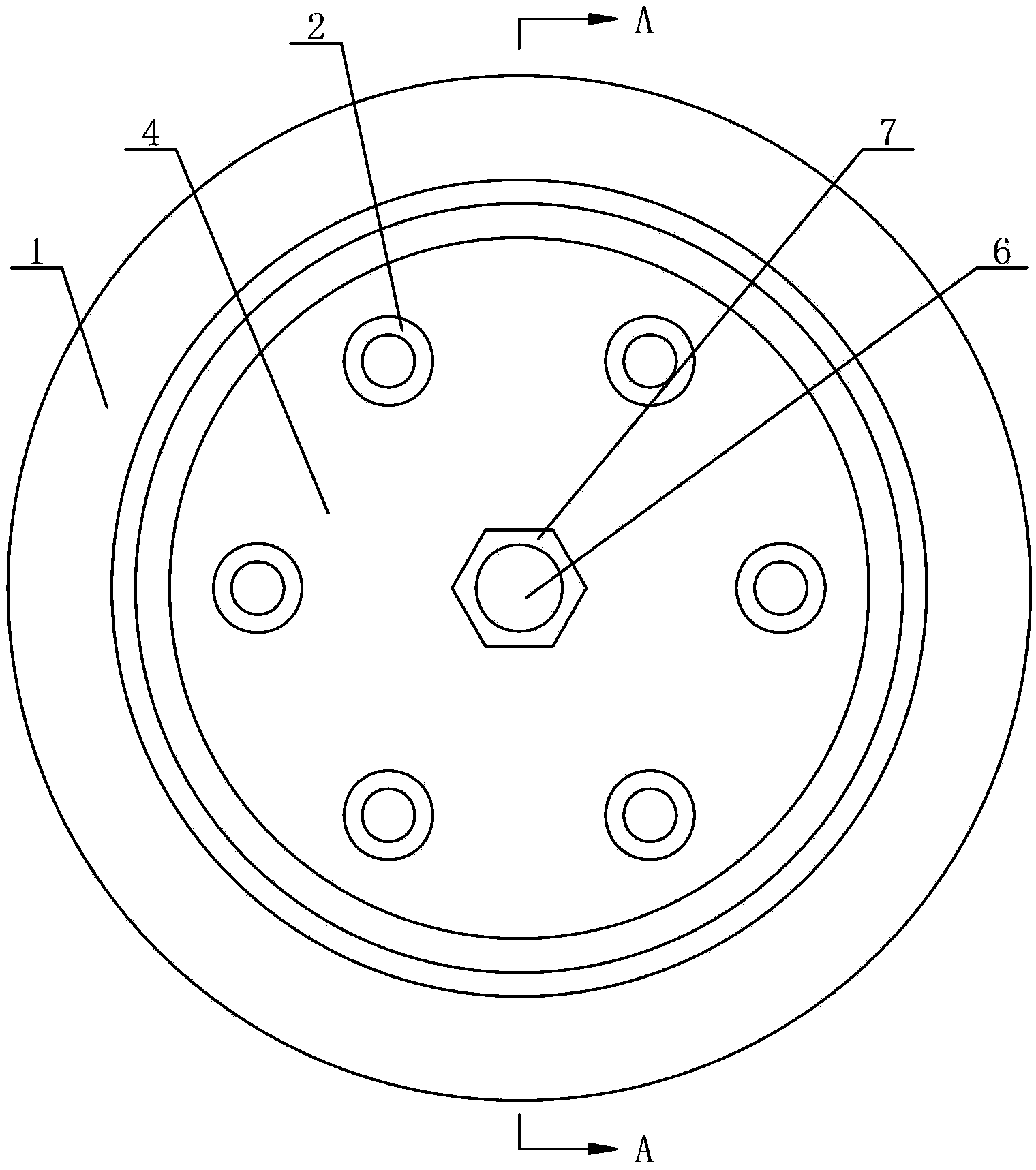

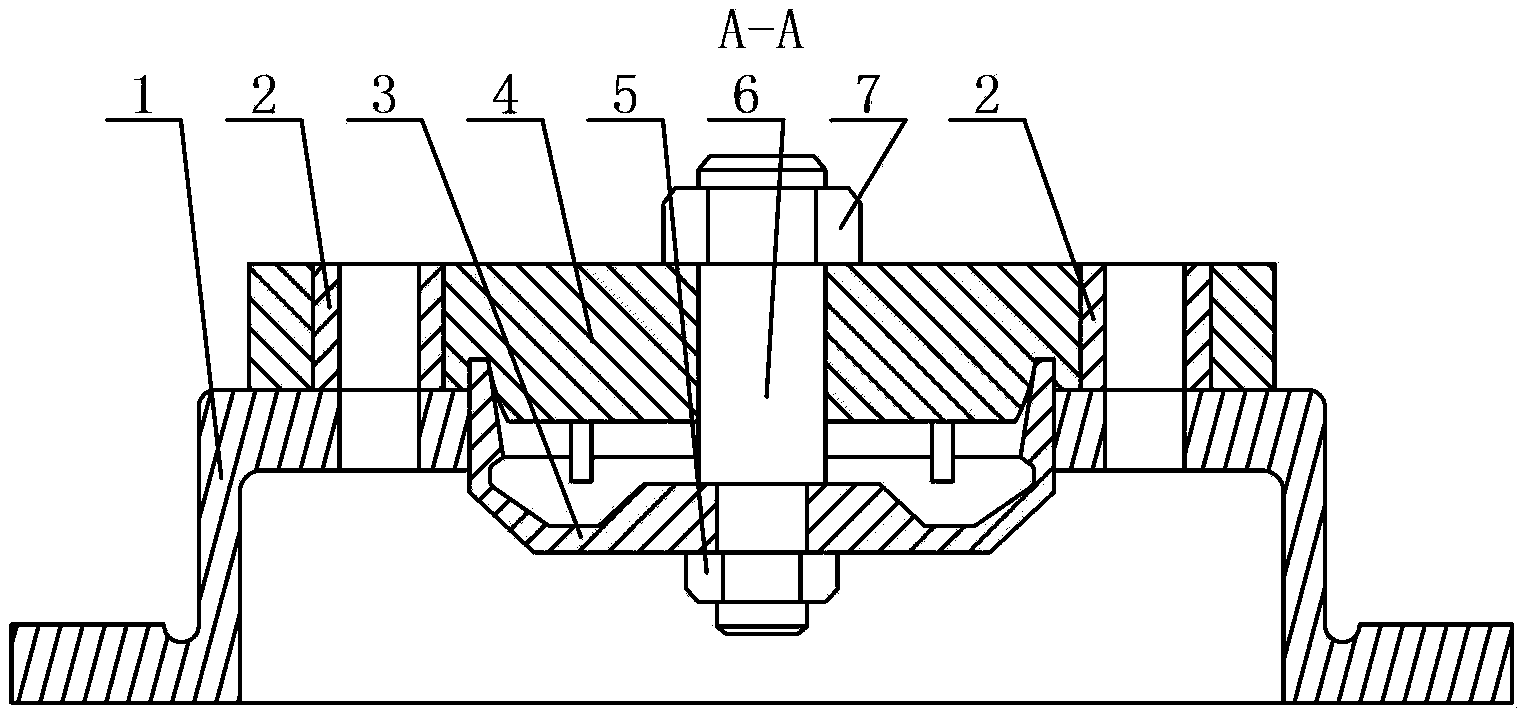

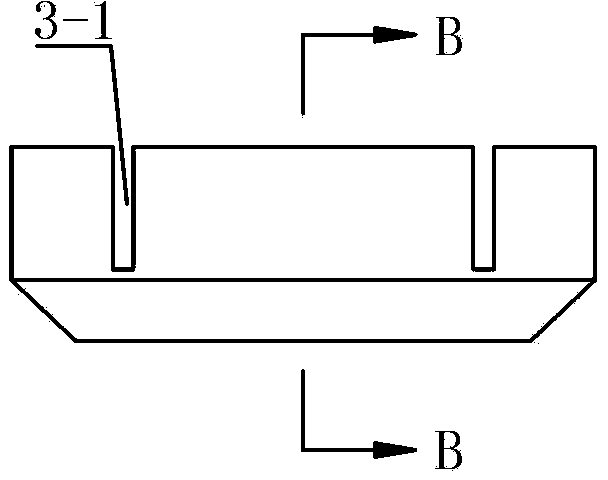

[0023] Such as Figure 1-Figure 5 The shown expansion sleeve expansion centering drilling fixture includes a drilling template 4 with a through hole 4-1 in the middle, a boss 4-2 is provided at the lower end of the drilling template 4, and the drilling template 4 is wound around A plurality of drill sleeves 2 are evenly arranged in the axial direction, and a stepped screw 6 is arranged in the through hole 4-1 in the middle of the drill template 4. The lower end of the stepped screw 6 passes through the disc-shaped expansion sleeve 3 and is installed with a lower nut 5. The upper end of the stepped screw 6 is equipped with an upper nut 7, and the upper side of the disc-shaped expansion sleeve 3 is uniformly provided with a plurality of expansion grooves 3-1 along its circumferential direction, and the inner hole of the disc-shaped expansion sleeve 3 is provided with a boss 4 -2 taper for slip fit.

[0024] Such as figure 2 and Figure 5 As shown, the boss 4-2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com