Lock core shell billiard hole drilling machine of numerical control mortise lock

A technology of lock cylinder shell and mortise lock, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., which can solve the problems of low efficiency and cumbersome process, and achieve improved efficiency, The effect of simplifying the manual operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

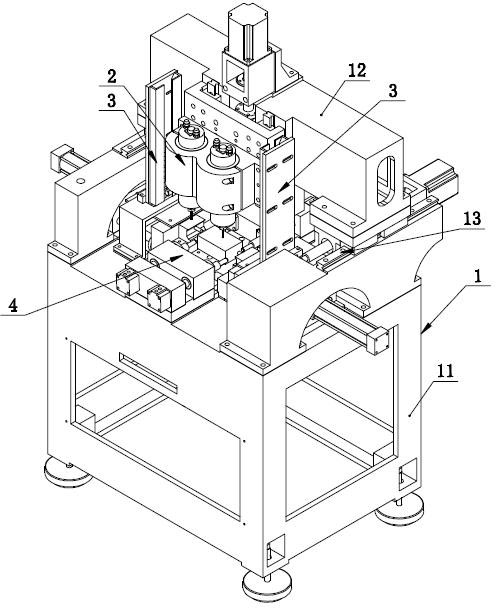

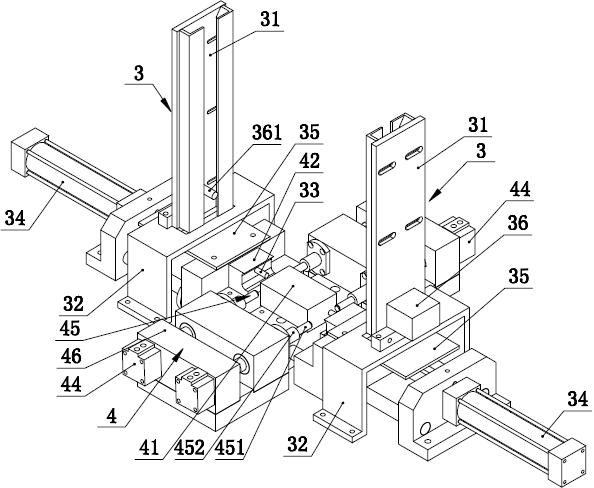

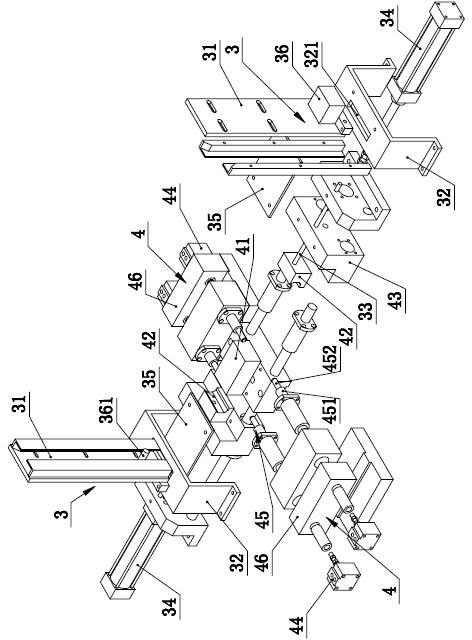

[0016] Such as figure 1 , 2 , 3, 4, and 5 show a kind of numerical control mortise lock lock core shell drilling bullet hole machine, including bed 1, drilling mechanism 2, feeding mechanism 3, positioning clamping mechanism 4 and control system, described The bed 1 is composed of a base 11 and a gantry frame 12, a guide rail and a guide post 13 are provided between the gantry frame 12 and the base 11, the drilling mechanism 2 is fixed on the gantry frame 12, and the feeding mechanism 3 and The positioning and clamping mechanism 4 is fixed on the base 11, the output end of the feeding mechanism 3 is connected with the positioning and clamping mechanism 4, and the positioning and clamping mechanism 4 clamps and positions the processed lock cylinder shell 5 sent out by the feeding mechanism 3. The hole mechanism 2 is used to complete the drilling operation of the processed lock core shell 5, wherein the feeding mechanism 3 includes a feeding trough frame 31, a feeding brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com