Inclined net knot-less screen printing plate and manufacturing method thereof

A production method and a technology without net knots, which are applied in screen printing machines, photographic plate-making processes on patterned surfaces, instruments, etc., can no longer meet the needs of SE screen production without net knots, increase raw material costs, and scrap nets. version and other issues, to achieve the effect of ensuring the etching yield, good protection of the screen frame, and reduced scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

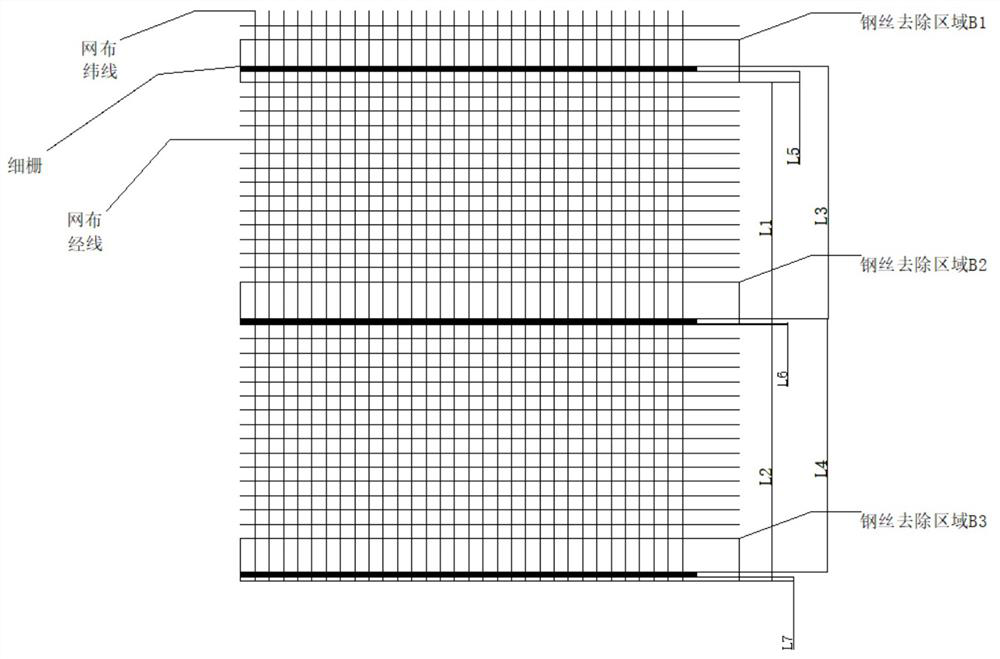

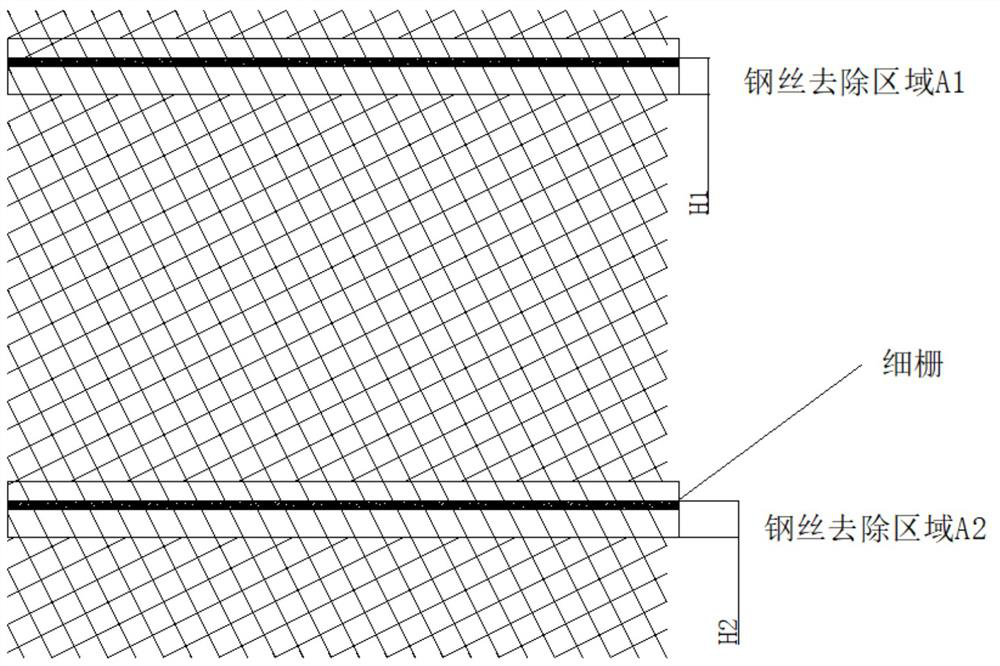

[0035] An oblique net knotless screen plate in this embodiment is characterized in that the screen plate is composed of an outer frame and steel wires stretched inside the outer frame, the steel wires are distributed in warp and weft, and the wires in warp and weft are distributed The stretching angle of the steel wire is greater than 0° and less than 180°, preferably, greater than 0°, less than 90°, greater than 90°, and less than 180°;

[0036] In this embodiment, the screen structure is optimized, and the inclined screen stretching screen design is adopted, which can effectively ensure the equal spacing of the etching area, prevent quality problems such as line collision caused by the fine grid and the etching area being too close, and can effectively improve the product yield. Reduce the raw material cost and production cost of the product.

Embodiment 2

[0038] A kind of production method of inclined net without net knot of the present embodiment is characterized in that, comprises the following steps:

[0039] S1: stretching the net, adjusting the stretching angle of the steel wire in the screen plate so that the stretching angle is greater than 0° and less than 180°, preferably greater than 0°, less than 90°, greater than 90°, and less than 180°;

[0040] S2: Coating the screen, coating the screen with photosensitive glue, and coating the S and P sides of the screen on both sides;

[0041] S3: Exposure, choose a suitable size film, paste it on both sides of the screen, and expose the S and P sides of the screen on both sides, the pattern area on the film corresponds to the preset area of the fine grid, and the preset area of the fine grid Distributed at equal intervals according to the requirements of design drawings;

[0042] S4: Development, remove the film on the exposed screen, and develop it, melt and remove the un...

Embodiment 3

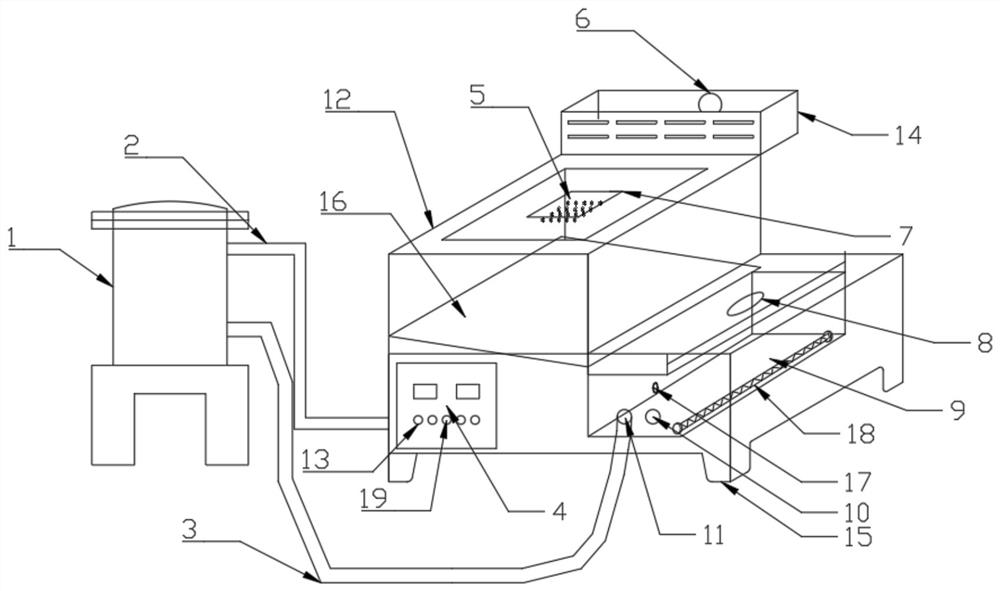

[0048] A method for making a slanted mesh without knots in this embodiment is characterized in that in step S5, the etching of the screen is carried out by etching equipment, and the etching equipment includes a filter 1 and a housing 12, and the outer wall of the filter 1 is a The upper and lower ends of the side are respectively equipped with a catheter assembly, one end of the catheter assembly is installed with a casing 12, the top side of the casing 12 is installed with a waste gas collection and discharge assembly, and the middle of the top of the casing 12 is installed with a jig to place the spraying assembly. , the middle of the inner wall of the shell 12 and the bottom of the spraying assembly are installed with a liquid guiding filter storage assembly, a heating temperature sensing assembly is installed in the liquid guiding filter storage assembly, a liquid drainage assembly is installed under one side of the liquid guiding filter storage assembly, and the guide The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com