Automatic arraying device of W-shaped workpieces

A technology for arranging devices and workpieces, which is applied in the field of mechanical parts processing, and can solve problems such as easy falling, high labor intensity, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

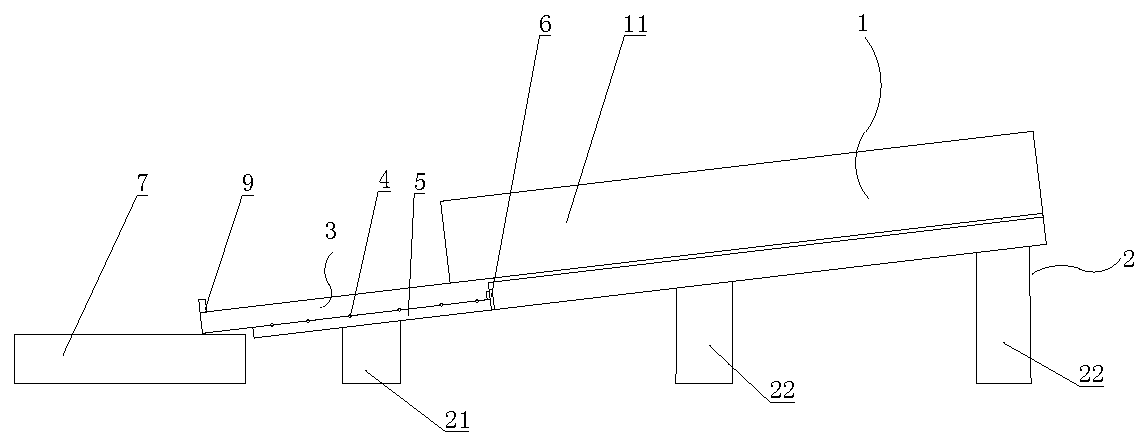

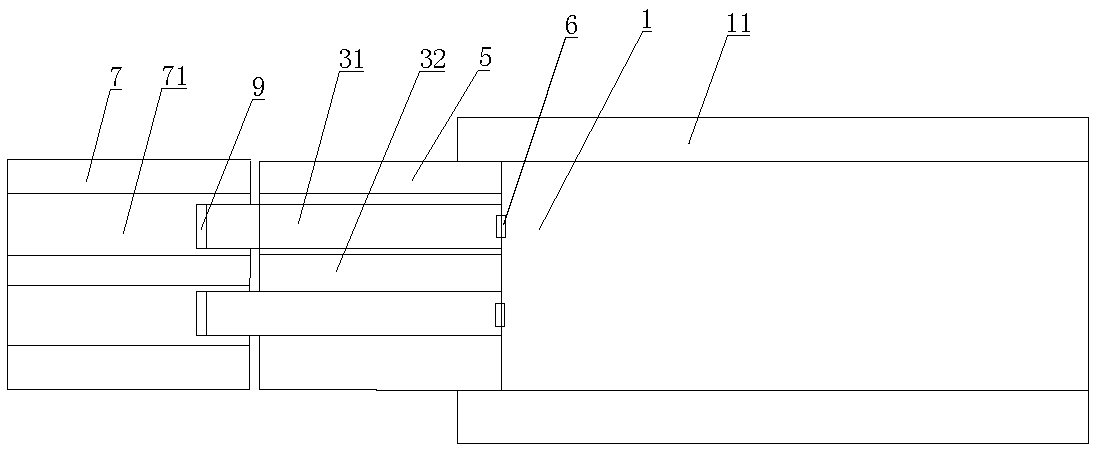

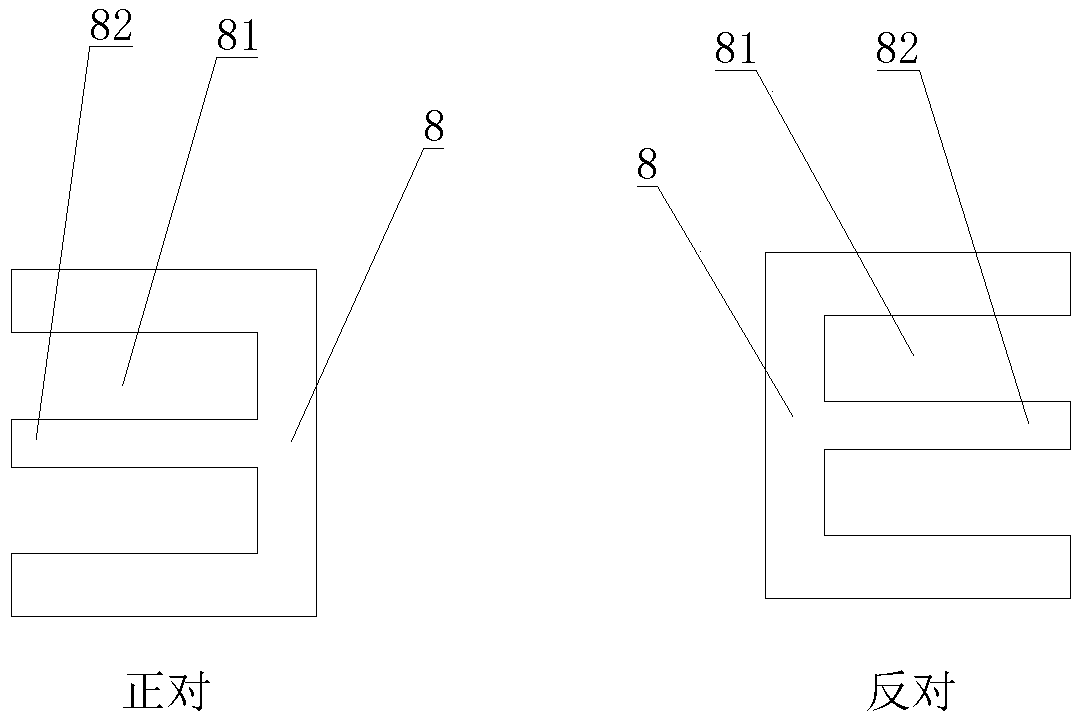

[0015] Such as figure 1 , figure 2 As shown, a W-shaped workpiece automatic alignment device includes a conveying chute 1 inclined to the outlet end at a certain angle with the horizontal plane. The conveying chute 1 is installed on a base 2, and the base 2 includes a first base 21 and two second bases. Base 22, the first base 21 is installed on the bottom end of the transfer platform slide track 5, and the second base 22 is respectively installed on the two ends of the bottom surface of the conveying chute 1. The heights of the first base 21 and the two second bases 22 are all different, which is convenient The conveying chute 1 is inclined to the direction of the parallel guide rail 31 at the outlet end at a certain angle with the horizontal plane;

[0016] The two side edges of the track of the conveying chute 1 are respectively equipped with baffle plates 11 perpendicular to the track, and the distance between the two side baffle plates 2 is greater than the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com