Full-automatic welding tool capable of achieving flat welding and vertical welding simultaneously

A fully automatic welding and tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that welding tooling is difficult to meet the precise and convenient positioning of space complex parts, so as to improve welding quality and improve Efficiency, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

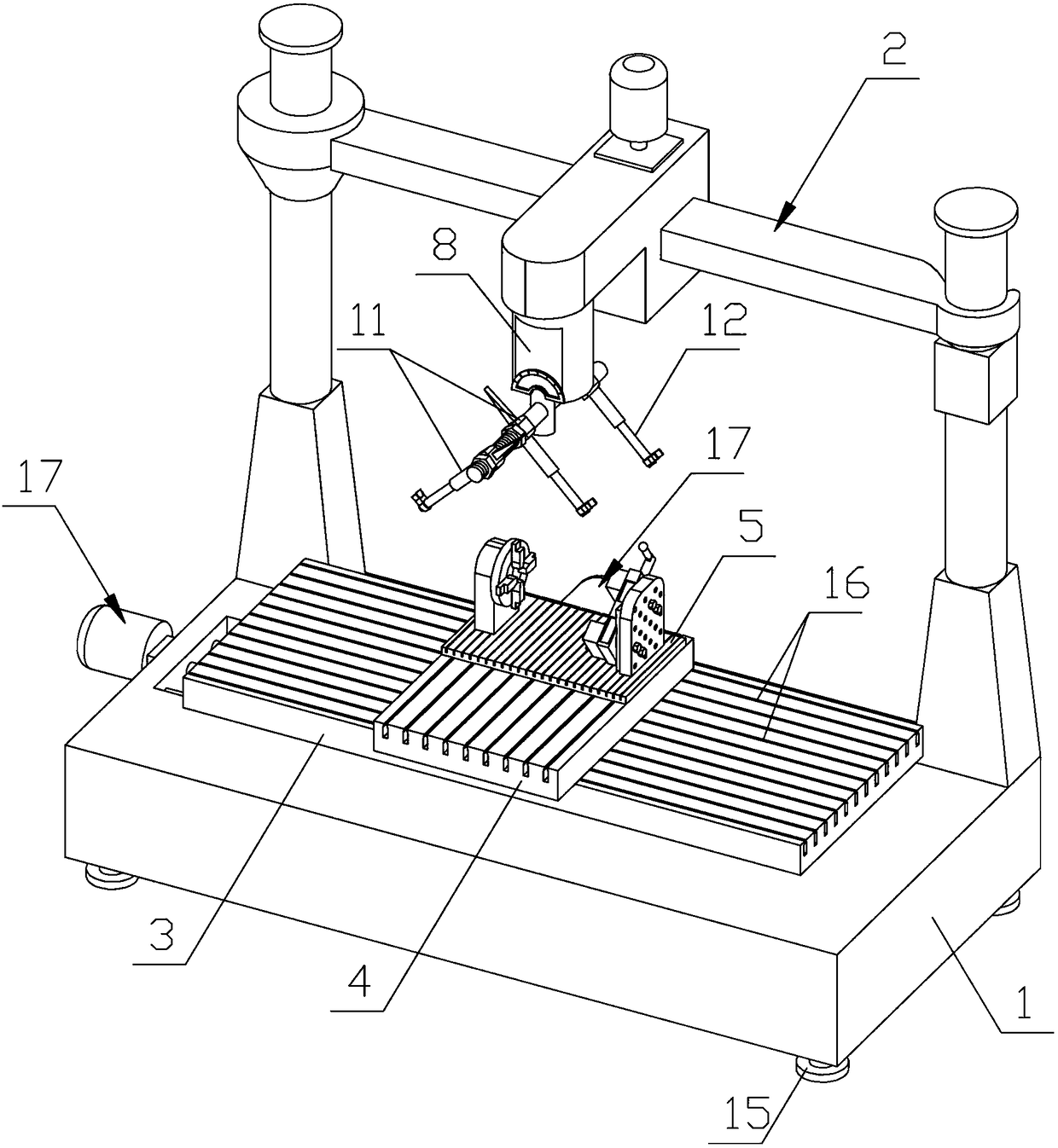

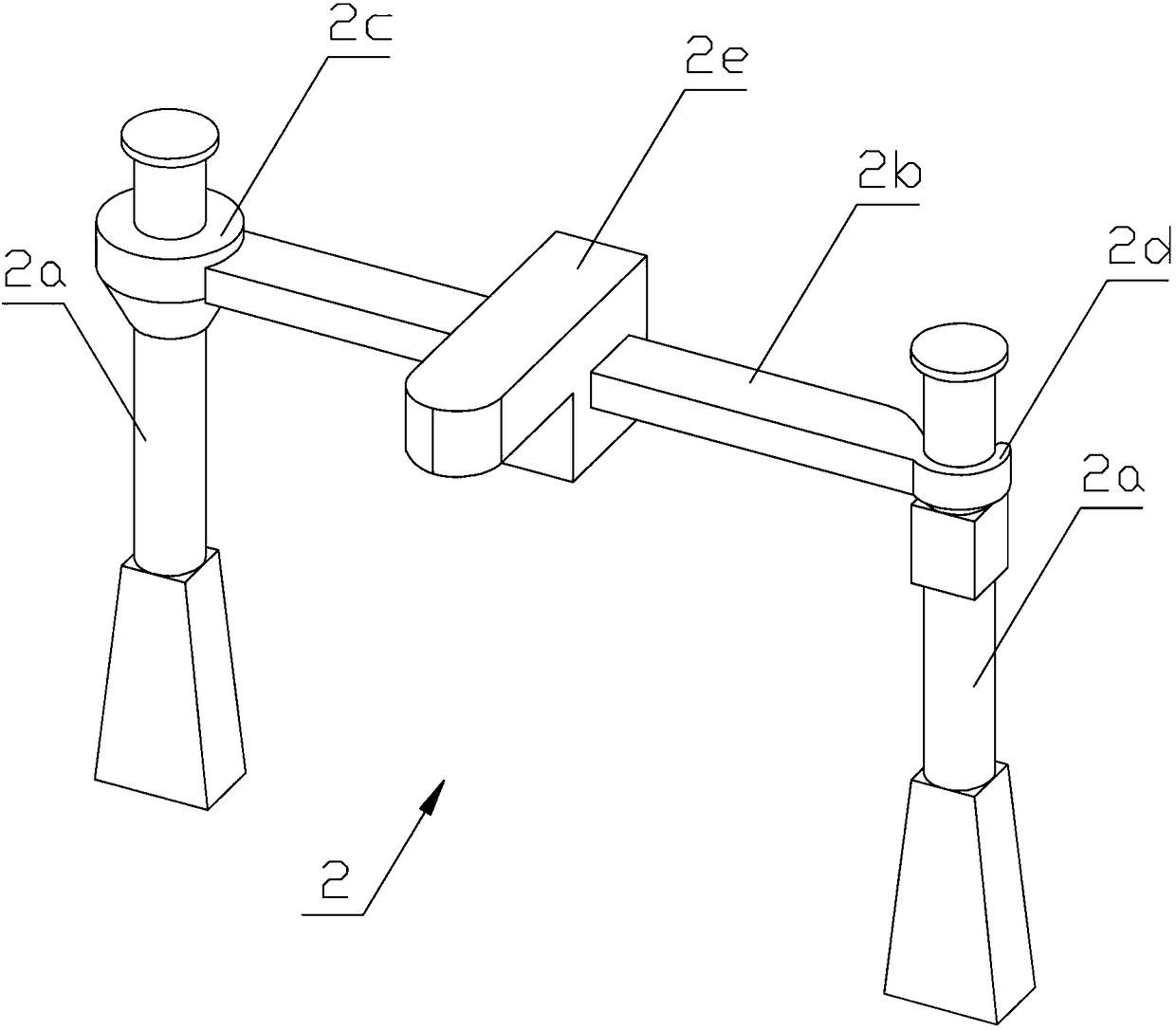

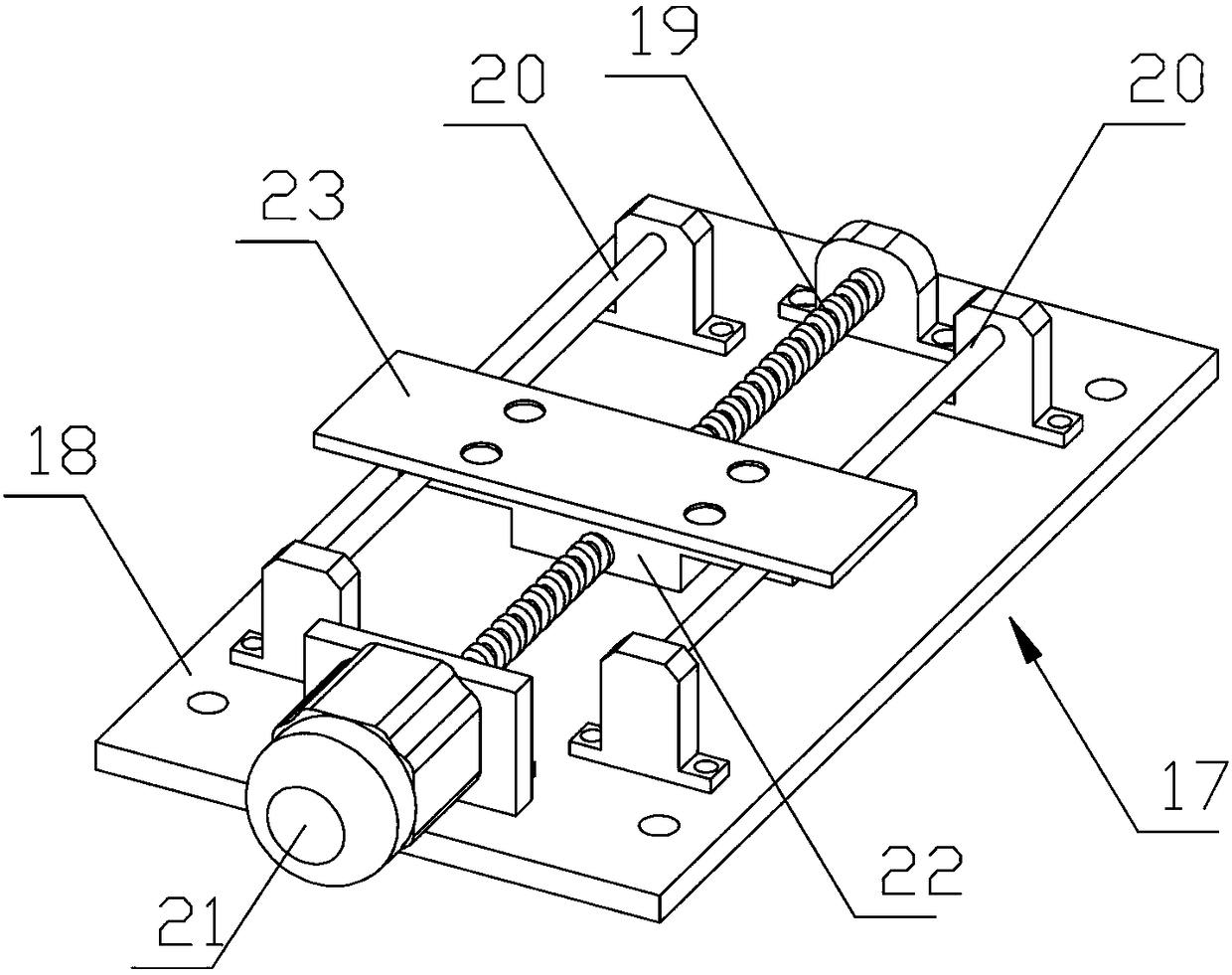

[0029] see Figure 1-6 , a fully automatic welding tool that can realize flat welding and vertical welding at the same time, including a frame composed of a base 1 and a hoisting bracket 2; an X-direction sliding table 3 that can slide horizontally along the X-direction is installed on the base 1, The X-direction slide 3 is equipped with a Y-direction slide 4 that can slide horizontally along the Y-direction; the Y-direction slide 4 is equipped with a horizontal workbench 5 for fastening welding foundation parts; , the right fixed seat 6,7, the clamping device that is used to realize the clamping and positioning of the welding separation part is housed between the left and right fixed seat 6,7; It is equipped with a main shaft 9 for realizing expansion and contraction along the Z direction. The telescopic end of the main shaft 9 extends out of the mechanism box 8, and a horizontal shaft 10 is installed at the end; two welding connecting rods are installed on the rod body on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com