Low-haze multi-layer co-extrusion two-way stretching polyamide film and preparation method

A polyamide film, multi-layer co-extrusion technology, applied in the field of packaging industry, can solve the problem of high haze of polyamide film, achieve the effects of low haze, improve toughness, and improve production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

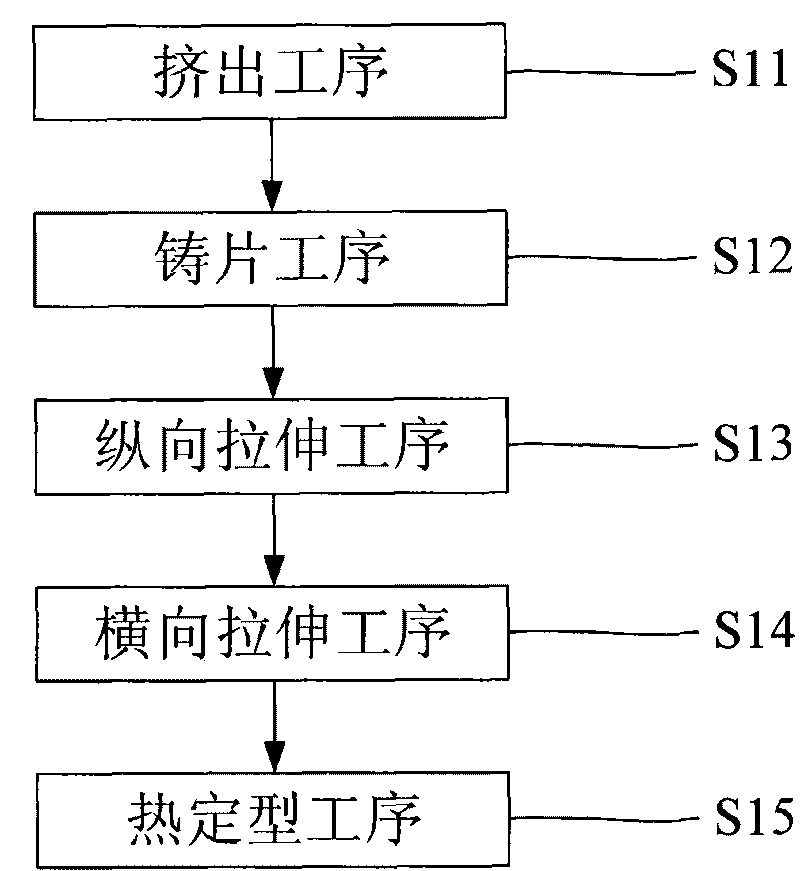

Method used

Image

Examples

Embodiment Construction

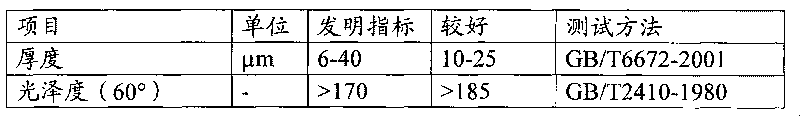

[0023] The main idea of the present invention is to add additives containing silica to polyamide raw materials, because there is good adhesion between silica and polyamide, so the voids on the film will be made after stretching the polyamide film less. Since voids are the main reason for the increase of film haze, the polyamide film added with silica can have good optical properties, such as very low haze, high gloss and transparency. Also, the smaller the silica particles used, the less voids there will be in the film and the lower the haze.

[0024] The low-haze multilayer co-extruded biaxially stretched polyamide film of the present invention comprises a three-layer structure: a surface layer A, a middle layer B and a surface layer C. The surface layer A and the surface layer C are respectively located on both sides of the middle layer B. The thickness of the surface layer A and the surface layer C can be the same or different, generally greater than 0.1 μm, usually in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com