Compact elastic fixed bearing

A fixed support and elastic fixation technology, which is applied to springs, vehicle components, and power plant gas intake, etc., can solve the problem that the fixed support cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

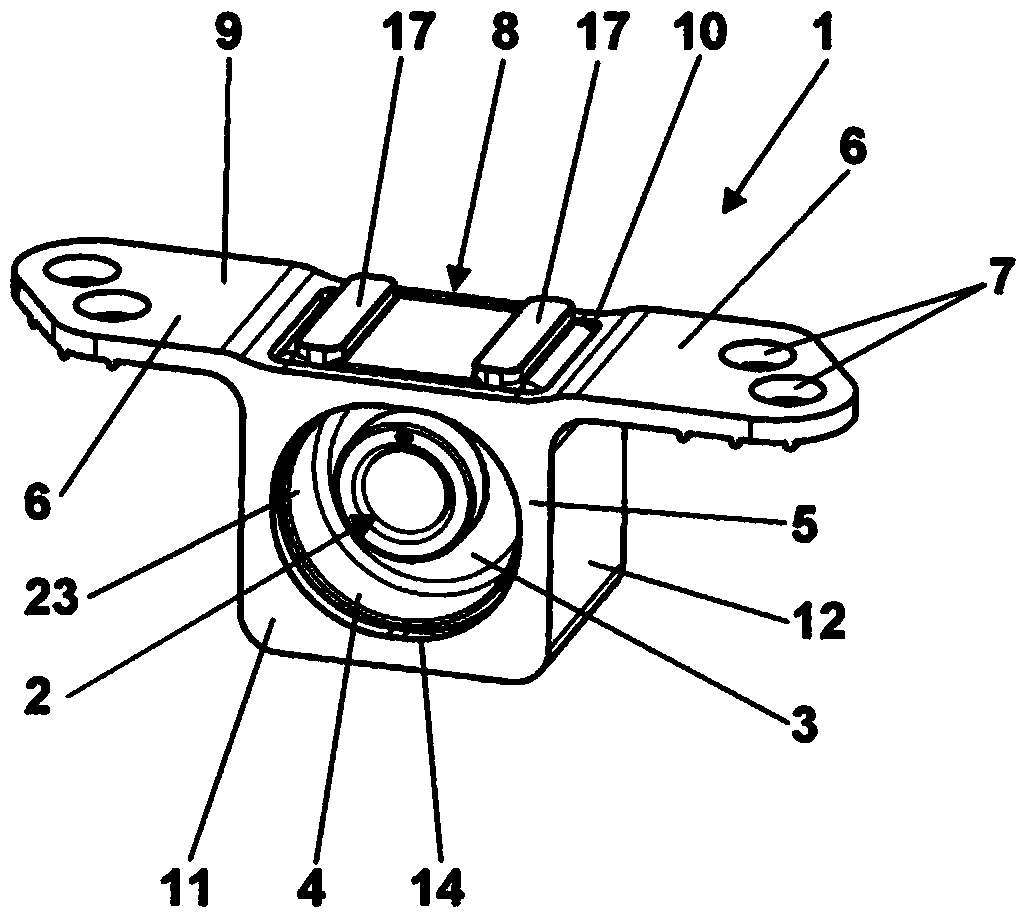

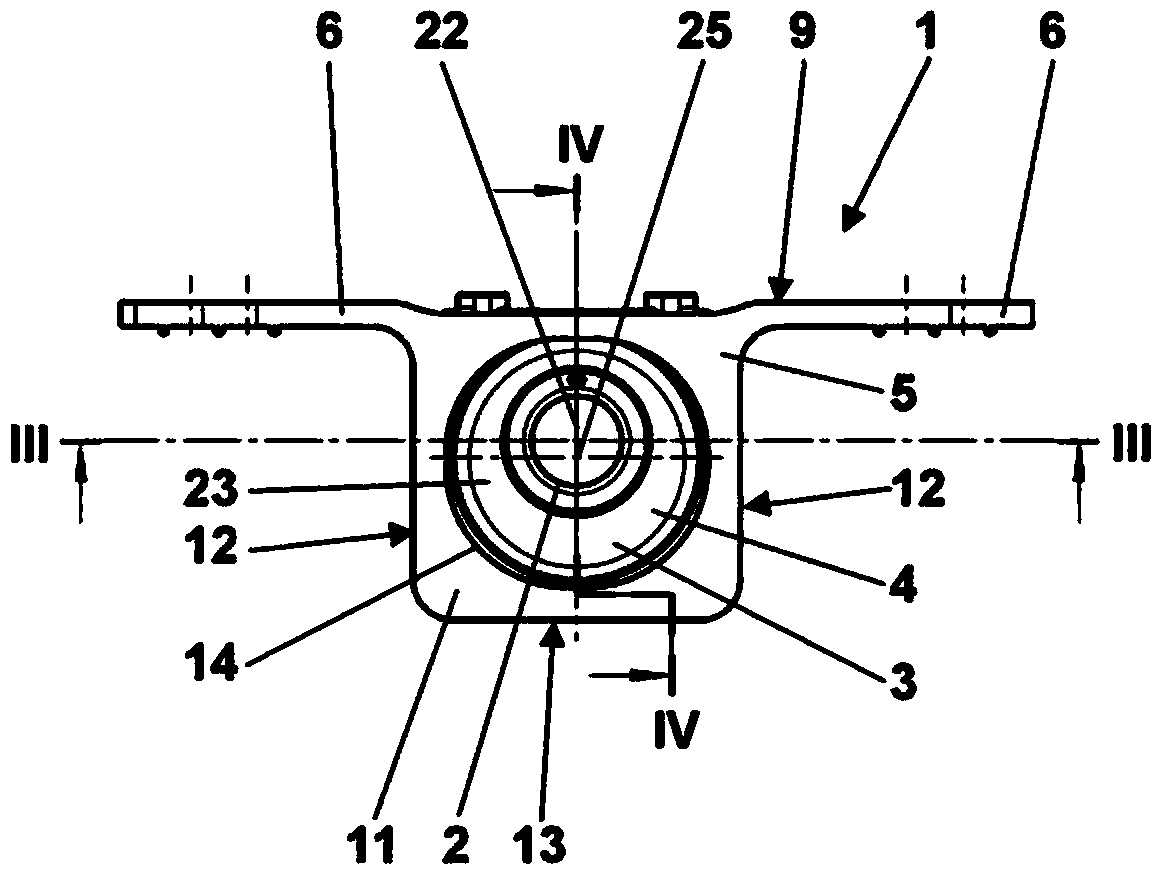

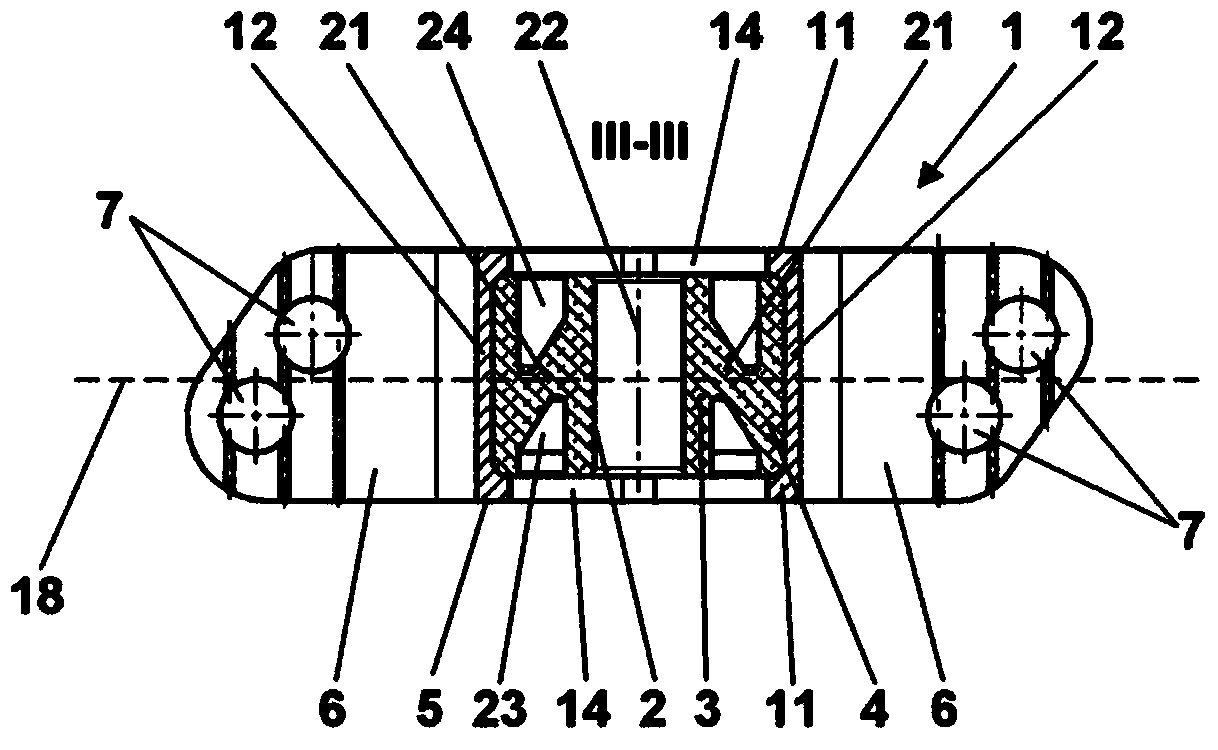

[0046] exist Figure 1 to Figure 4 in various views as a whole and in Figure 5 and Figure 6 The fastening support 1 , shown in its two individual parts, is used for mounting an exhaust system, not shown here, on the underbody of a motor vehicle, likewise not shown here. For the exhaust gas system, the fixed bearing has a bearing bush 2 . The bearing bush is part of the elastic body 3 made of elastomer material 4 . The elastic body 3 is produced separately from the elastomer material 4 and then inserted into a dimensionally stable frame 5 . The dimensionally stable frame 5 has a suspension 6 with fastening bores 7 for rigid fastening to the vehicle floor. In this fastening condition, an opening 8 in the upper side 9 of the rigid frame 5 is closed, through which opening the elastic body 3 is inserted into the frame 5 . The elastic body 3 is arranged in a cavity 10 in the frame 5 , wherein the cavity 10 has a rectangular parallelepipedal basic shape. All walls 11 to 13 deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com