Spinning and conglutinating method polylactic acid nonwovens preparation method

A non-woven fabric, polylactic acid technology, applied in non-woven fabrics, textiles and papermaking, single-component polyester rayon, etc., can solve the problems of uneven fibers, strength not as good as spunbond method, etc., and achieve easy biodegradation. , excellent mechanical properties, rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

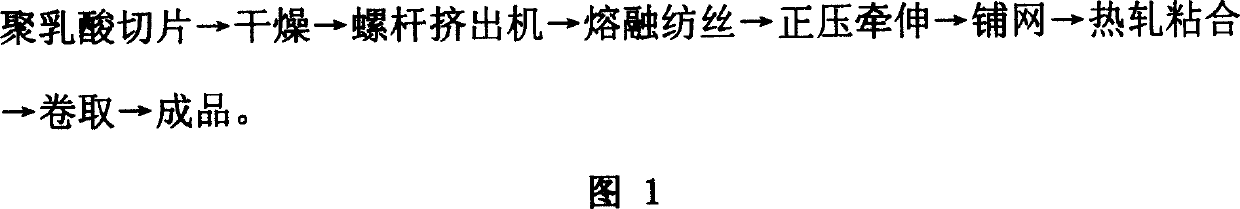

Method used

Image

Examples

Embodiment 1

[0019] Polylactic acid with 99 mol% of L-isomer, number average molecular weight of 7,5762, weight average molecular weight of 15,2818, and MFI=32 is used as raw material, and dried at a vacuum of 65 Pa and a temperature of 70°C for 24 hours.

[0020] The dried polylactic acid chips are placed in a screw extruder for melt spinning. The spinning temperature is 195℃, and 48 spinnerets with 106 holes×Φ0.2mm are used to form a spinneret with a total length of 3120mm. Spinning, the spinning pump is a 2.4cc stack pump with a rotation speed of 36 rpm; meanwhile, the obtained polylactic acid nascent fiber is stretched under positive pressure, the pressure of the compressed air is 0.15 MPa, and the stretching speed is 4000 m / min. about.

[0021] The stretched polylactic acid wire is oscillated and moved forward and laid into a net through a wire-separating netting device. When the oscillating amplitude is 25cm, the oscillating frequency is 800 times / min, and the moving speed is 52.6m / min, ...

Embodiment 2

[0024] Using polylactic acid with an L-isomer accounted for 97 mol%, a number average molecular weight of 9,7886, a weight average molecular weight of 235008, and MFI=20 as a raw material, it was dried and balanced at a vacuum of 20 Pa and a temperature of 80°C for 14 hours. In the same device as mentioned above, the spinning temperature is 210°C, the speed of the metering pump is 36 rpm, the pressure of the compressed air is 0.35 MPa, and the drawing speed is about 2354 m / min. When the swing amplitude of the device is 10cm, the swing frequency is 500 times / min, and the moving speed is 26m / min, 60g / m is obtained. 2 The door width is 3 meters of fiber mesh.

[0025] Then the obtained polylactic acid fiber web was pressurized by a hot roll at 155°C with a pressure of 60KG for thermal bonding. Finally, the coil obtained a longitudinal tensile strength of 75N / 5cm, a transverse tensile strength of 53N / 5cm, and an elongation of Polylactic acid spunbond fabric with 40% and 15N / 5cm tear s...

Embodiment 3

[0027] Using polylactic acid with an L-isomer accounted for 97 mol%, a number average molecular weight of 9,7886, a weight average molecular weight of 235008, and MFI=20 as a raw material, it was dried and balanced for 48 hours at a vacuum degree of 50 Pa and a temperature of 60°C. In the same device as mentioned above, the spinning temperature is 210°C, the speed of the metering pump is 40 rpm, the pressure of the compressed air is 0.15 MPa, and the drawing speed is about 1457 m / min. When the swing amplitude of the device is 10cm, the swing frequency is 300 times / min, and the moving speed is 12m / min, 145g / m is obtained. 2 The door width is 3 meters of fiber mesh.

[0028] Then the obtained polylactic acid fiber web was pressurized by a hot roll at 160°C with a pressure of 60KG for thermal bonding. Finally, the coil obtained a longitudinal tensile strength of 150N / 5cm, a transverse tensile strength of 118N / 5cm, and an elongation of Title product with 57% and tear strength of 28.5N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com