Numerical control method for cam synchronous transmission jacquard loom

A jacquard loom and synchronous transmission technology, applied in the direction of digital control, electrical program control, etc., can solve the problems that affect the quality and efficiency of weaving, cannot meet the time requirements, and the edge yarn breaks, etc., to improve the weaving quality and weaving efficiency, Eliminate potential safety hazards and stabilize weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

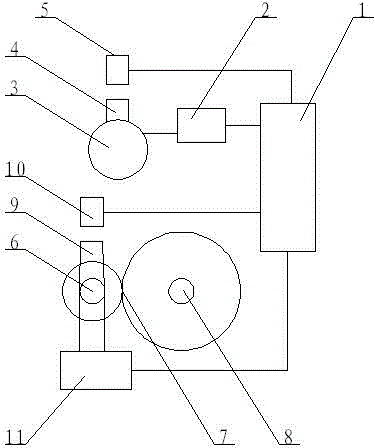

[0013] figure 1 As shown, a cam synchronous transmission jacquard loom includes a control electric box 1, a pulse generator 2, a jacquard loom main shaft 3, a main shaft signal origin signal convex 4, a main shaft proximity switch 5, a jacquard machine input shaft 6, and a gear transmission group 7. Jacquard rotating wheel shaft 8, Jacquard signal projection 9, Jacquard proximity switch 10, numerically controlled motor and reduction mechanism 11. The main shaft origin signal convex 4 is set on the main shaft 3 of the jacquard loom, the main shaft proximity switch 5 is set correspondingly to the main shaft signal convex 4, the main shaft 3 of the jacquard loom is synchronously connected to the pulse generator 2, and the main shaft proximity switch 5 and the pulse generator 2 are both It is connected to the control electric box 1, and the control electric box 1 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com