Belt friction type conveying machine

A belt conveyor, friction technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems that affect the transmission efficiency and inconvenience, and achieve the effect of improving the transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

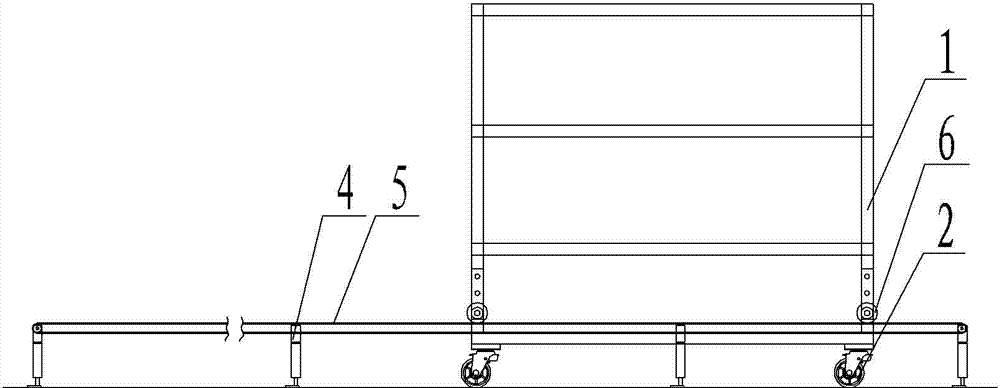

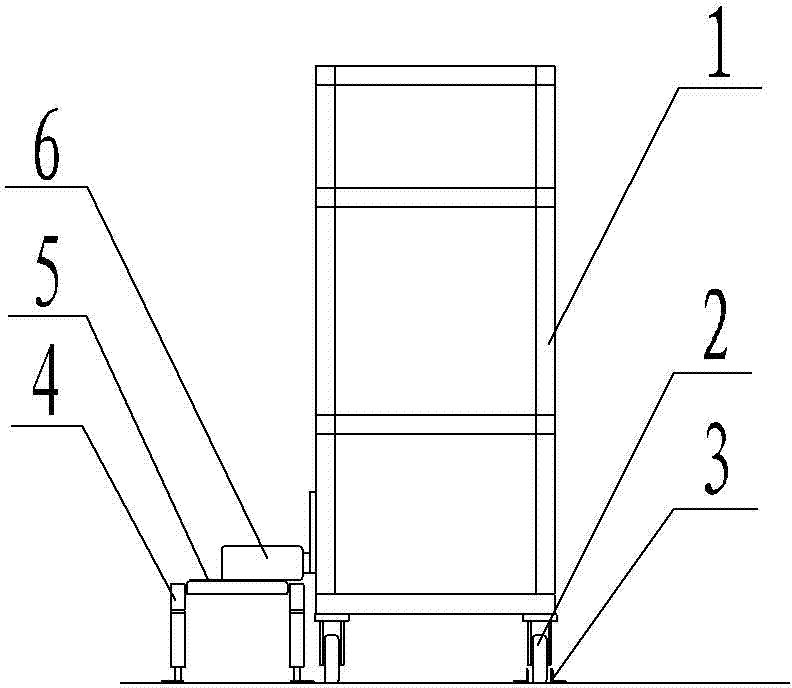

[0009] See figure 1 , figure 2 As shown, a belt friction conveyor includes a trolley 1, and the trolley 1 includes a trolley caster 2, and the trolley caster 2 on one side is located in the guide rail 3, and the other side of the trolley 1 is provided with a belt conveyor 4. The belt 5 of the belt conveyor 4 is a rough belt, corresponding to the belt conveyor 4, two rough-surfaced friction rollers 6 are installed on the trolley 1, which are respectively located at the front end and the rear end of the trolley 1.

[0010] The working principle is as follows: Push the trolley caster 2 on one side of the trolley 1 into the guide rail 3, the friction roller 6 on the other side contacts the belt 5 of the belt conveyor 4, and the belt conveyor 4 is started, and the belt 5 goes to the Moving forward, because the surface of the belt 5 is relatively rough and the friction coefficient is high, the surface of the friction roller 6 is also rough, the friction between the two is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com