Sorting devices for logistics sorting machine

A technology for sorting devices and sorting machines, which is applied in the direction of sorting, conveyors, conveyor objects, etc., can solve the problems of high manufacturing and use costs, easily damaged and damaged parts, and low energy utilization rate, so as to avoid damage , low energy consumption, and the effect of reducing manufacturing cost and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

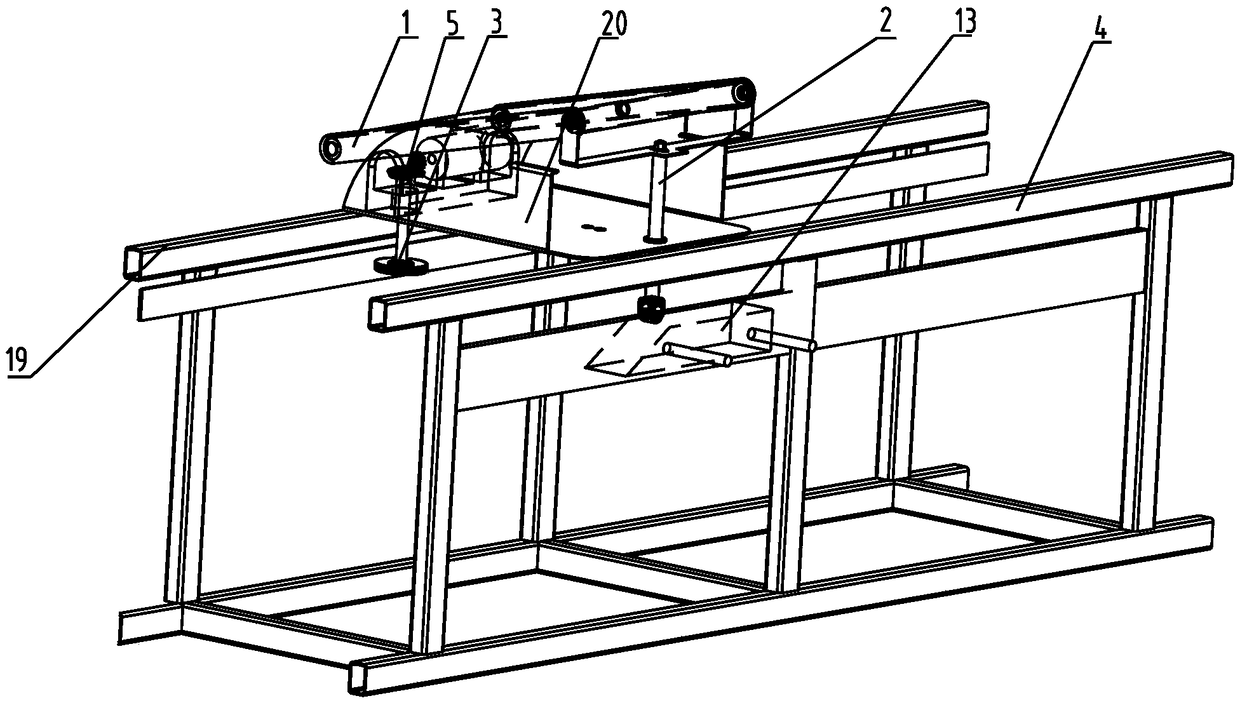

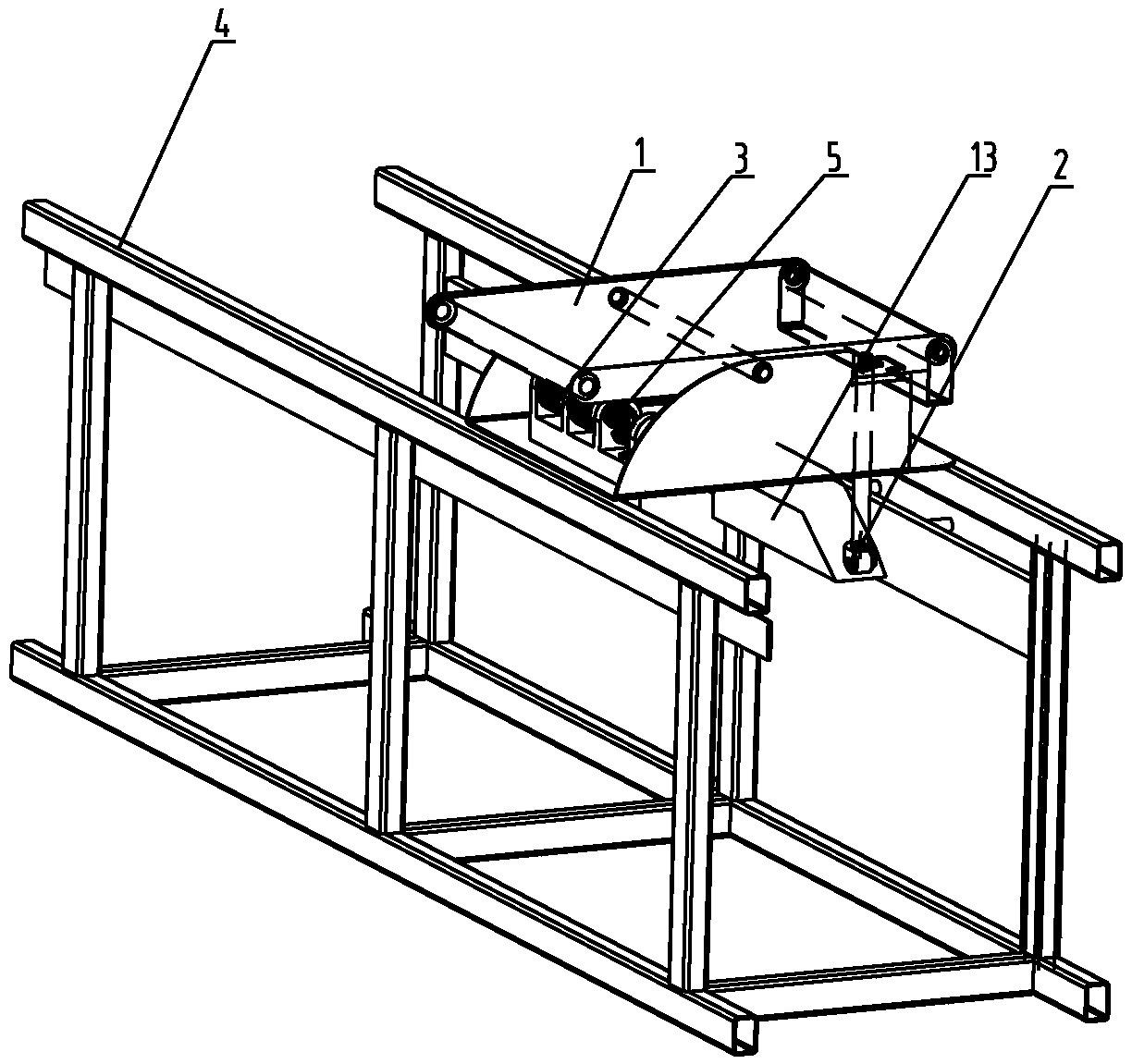

[0024] like Figure 1-Figure 6 As shown, a sorting device of a logistics sorter includes a tiltable belt transmission mechanism 1 , a wedge mechanism 2 , a box body 20 , a friction wheel power mechanism 3 and a main frame 4 .

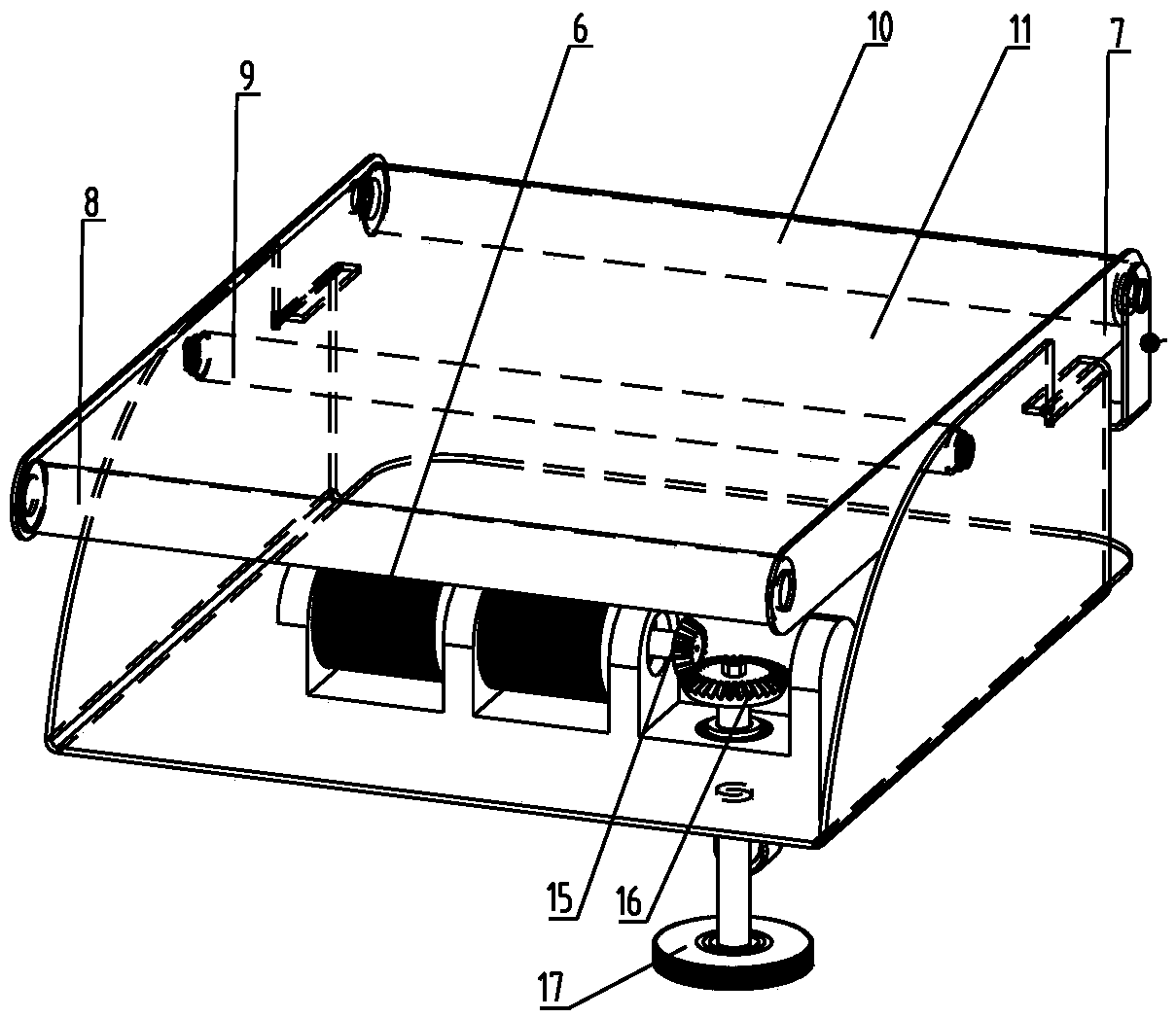

[0025] The inclined belt transmission mechanism 1 includes a frame body 7 , a front roller 8 , an overturning center shaft 9 , a rear roller 10 and a transmission belt 11 . The front roller 8 , the turning axis 9 and the rear roller 10 are installed on the frame body 7 in sequence, and the transmission belt 11 is installed on the front roller 8 and the rear roller 10 . The tiltable belt transmission mechanism 1 is hinged on the box body 20 through the turning axis 9, and the tiltable belt transmission mechanism 1 rotates with the turning axis 9 as the axis.

[0026] The wedge mechanism 2 includes a pull rod 12 , a wedge block 13 , and a guide sleeve 14 . One end of the pull rod 12 is fixed on the rear part of the frame body 7 of the tiltable belt tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com