A roller belt conveyor

A technology for belt conveyors and rollers, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problems of reducing belt friction coefficient, easy formation of ice layer, conveyor belt deviation, etc., to avoid the external Circumferential deformation, improve structural strength, and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

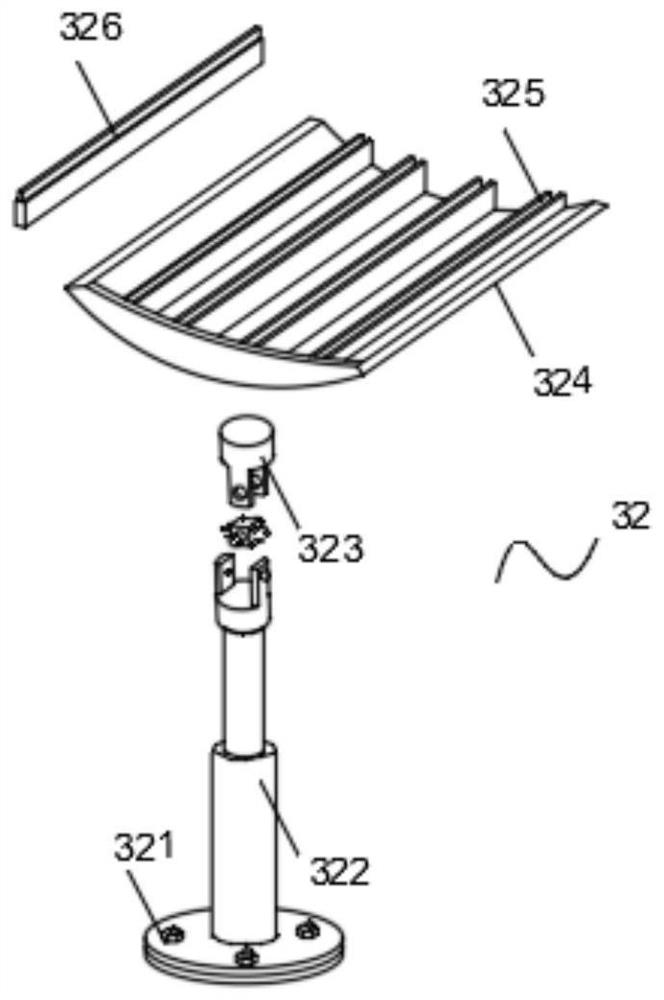

[0046] As an embodiment of the present invention, such as Figure 8 As shown, the connecting mechanism 323 includes a first connecting piece 3231, a cross connecting shaft 3232 and a second connecting piece 3233; the lower end of the first connecting piece 3231 is fixedly connected to the telescopic rod 322; the upper end of the second connecting piece 3233 is connected to The mounting plate 324 is fixedly connected; the second connecting piece 3233 and the first connecting piece 3231 are rotationally connected through the cross connecting shaft 3232; during work, the mounting plate 324 and the scraper 326 on the dirt scraping mechanism 32 need to be adjusted in angle, In order to fit the inclination angle of the installation plate 324 with the installation inclination angle of the idler body 34, the present invention sets the connection mechanism 323, and the second connection part 3233 and the first connection part 3231 are rotationally connected through the cross connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com