Driving device used for new energy car motor rotor balancing machine

A new energy vehicle, motor rotor technology, applied in the direction of electromechanical devices, transmission devices, static/dynamic balance testing, etc., can solve the problems of small rotor outer diameter range, inconvenient adjustment of belt wrap angle, etc., and achieve large belt friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

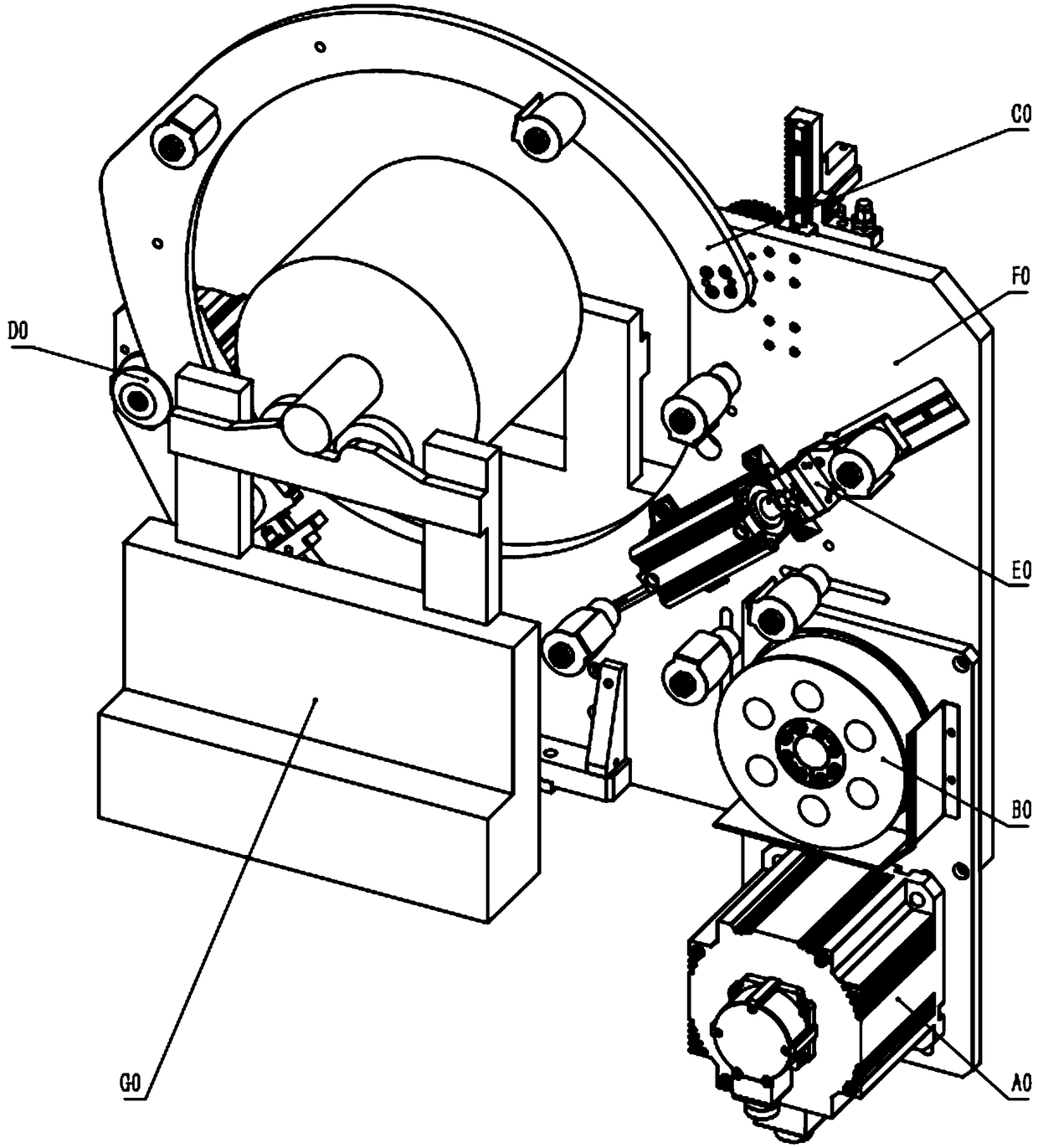

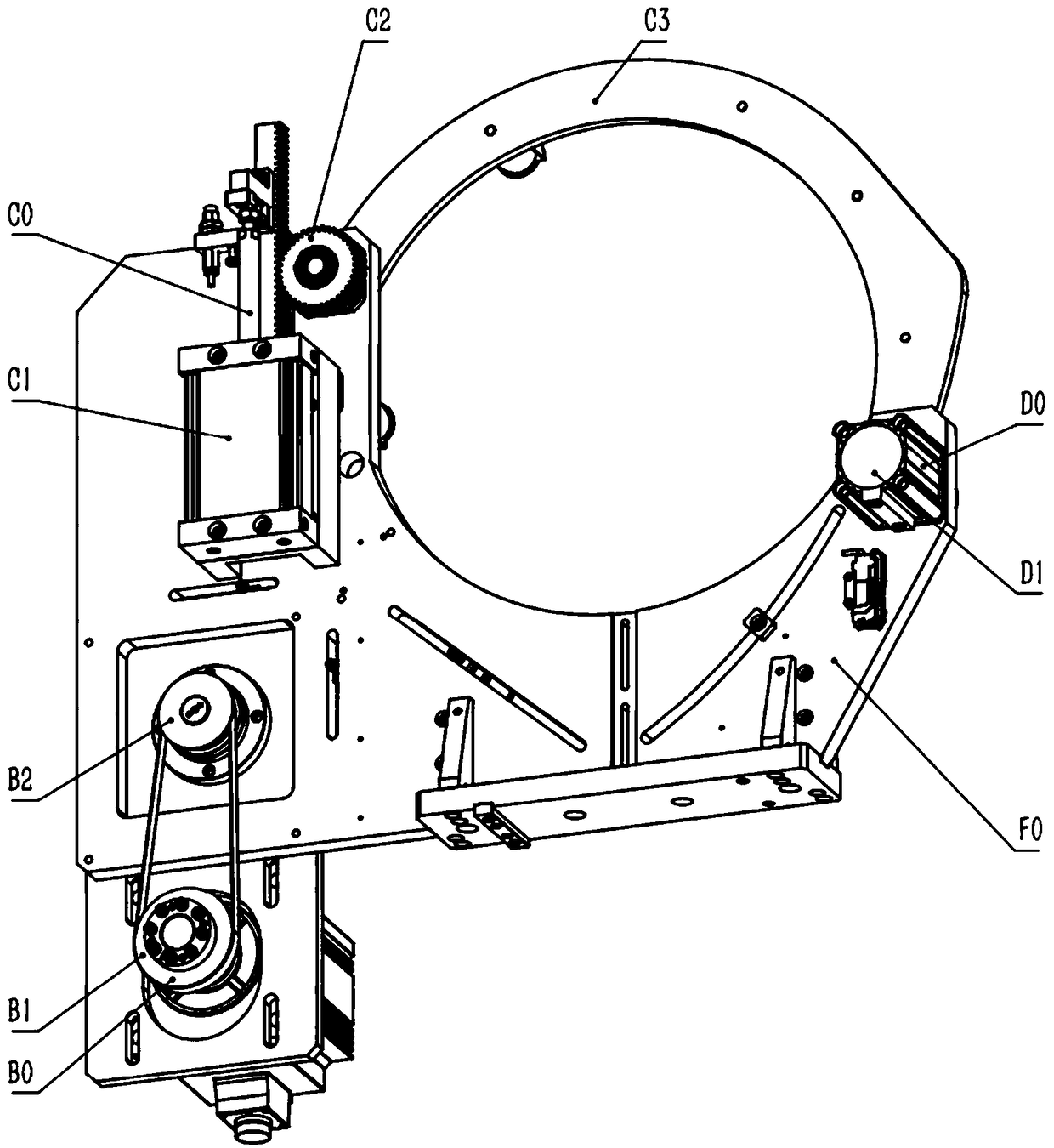

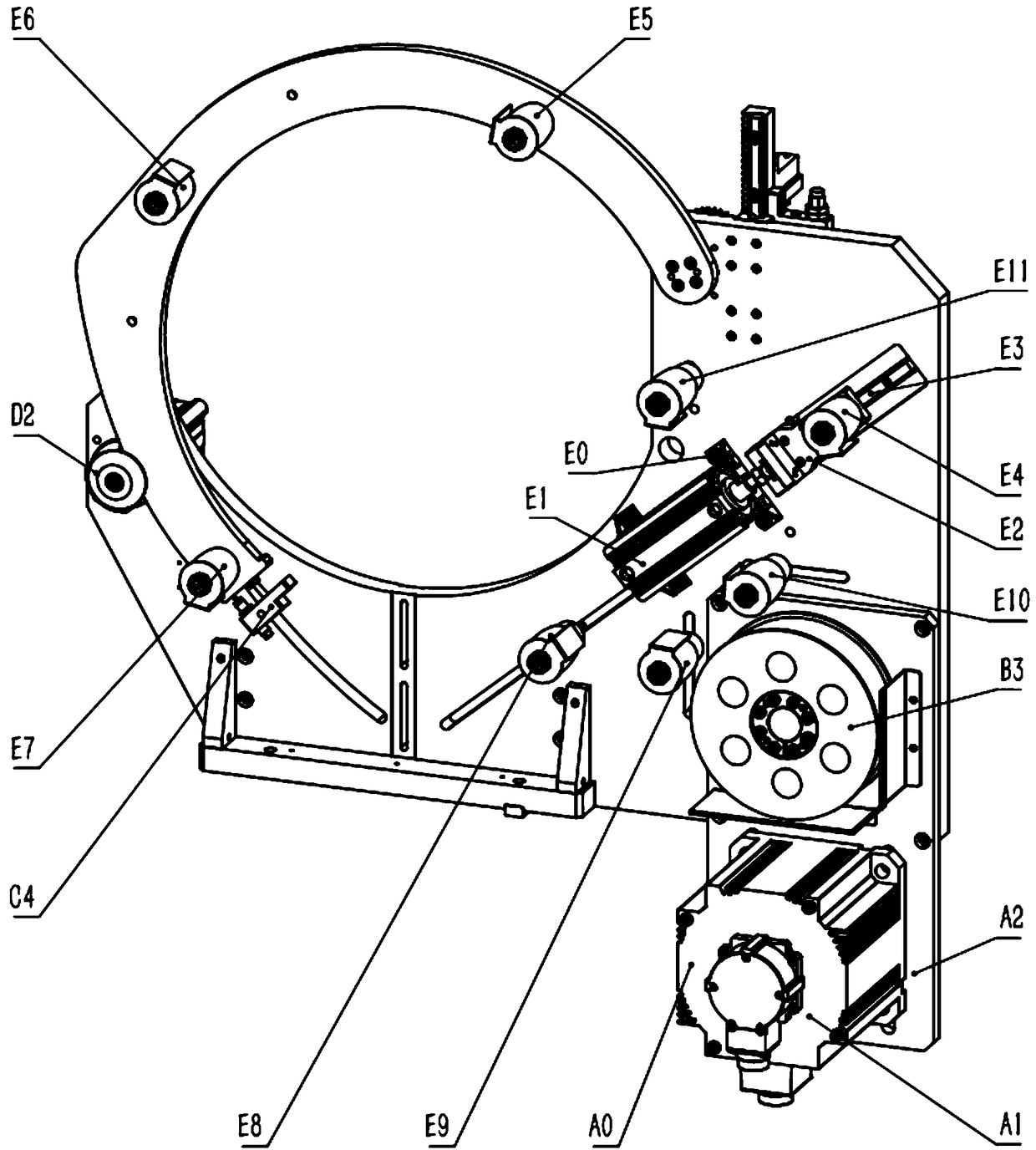

[0032] like figure 1 As shown, the specific implementation of the present invention includes a driving mechanism base F0 and a power assembly A0, a transmission assembly B0, a belt pressing assembly C0, a driving arm clamping assembly D0 and a belt tensioning assembly E0 installed on the driving mechanism base F0; The driving mechanism base F0 is a vertical plate, and the upper part of the driving mechanism base F0 has an arc-shaped gap, and the motor rotor is placed in the center of the arc-shaped gap. The lower component C0 is movably connected and installed between the two sides of the upper part of the drive mechanism base F0 and spans the arc-shaped gap; the power component A0 and the transmission component B0 are installed at the bottom of the drive mechanism base F0, and the power component A0 and the transmission component B0 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com