Underground coal mine fully mechanized coal mining face high-voltage cable no-twisting rolling device

A technology of fully mechanized mining face and high-voltage cable, applied in the field of mining machinery, can solve the problems of time-consuming and laborious cable winding, large torsion force of the cable coil, and difficulty in unfolding, etc., to reduce labor intensity, reduce extrusion and wear, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

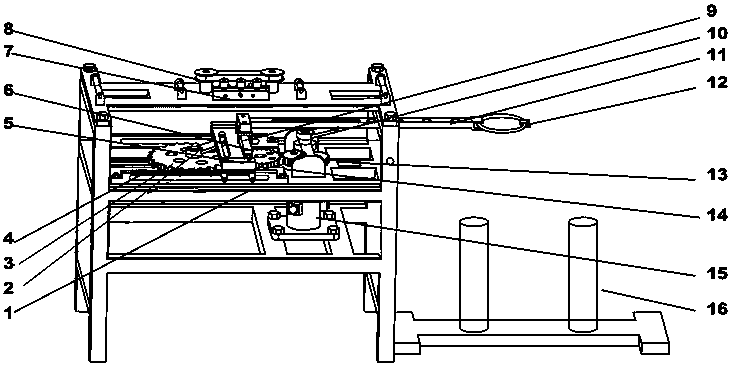

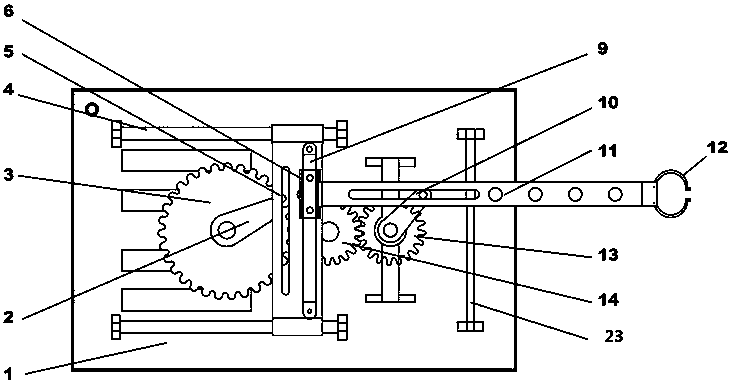

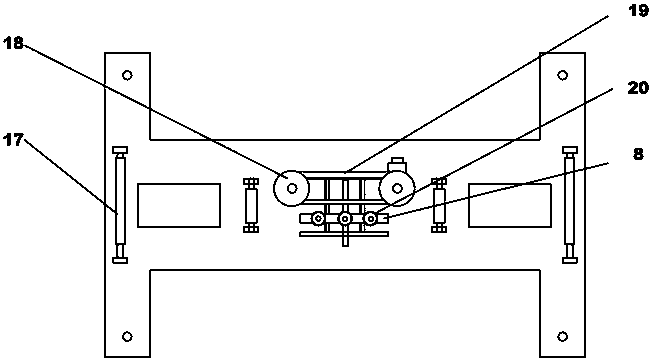

[0017] The present invention is described in detail in conjunction with accompanying drawing: as figure 1 , 3 As shown, the invention discloses a cable conveying device, figure 2 Shown is the cable conveying device, the cable pressing mechanism presses the cable to the flat belt surface of the flat belt friction conveying mechanism, and then passes through the cable clamp 12; driven by its own hydraulic motor, the flat belt friction conveying mechanism 8 exerts pressure on the redundant cables on the working surface With controllable dragging, the cable passes through the cable clamp 12, and is rewound by the winding "8" device.

[0018] like figure 1 , 2 , 4, the present invention discloses a cable winding "8" device, image 3 Shown is the cable winding "8" device, in the "8" device, the low-speed hydraulic motor drive device drives the pinion 13 to rotate, the large gear 3 is meshed with the pinion 13 through the idler 14, and the pinion and the large gear The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com