Conveying device

A conveying device and carrier technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of large space occupation, high cost, inaccurate conveying positioning, etc., and achieve accurate hovering position and less space occupation. , the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

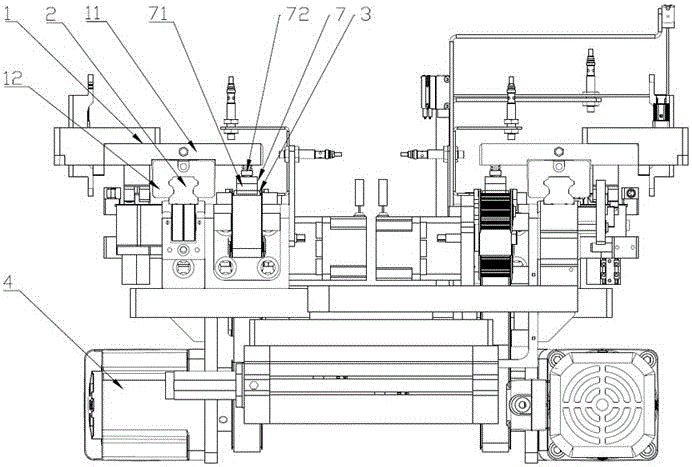

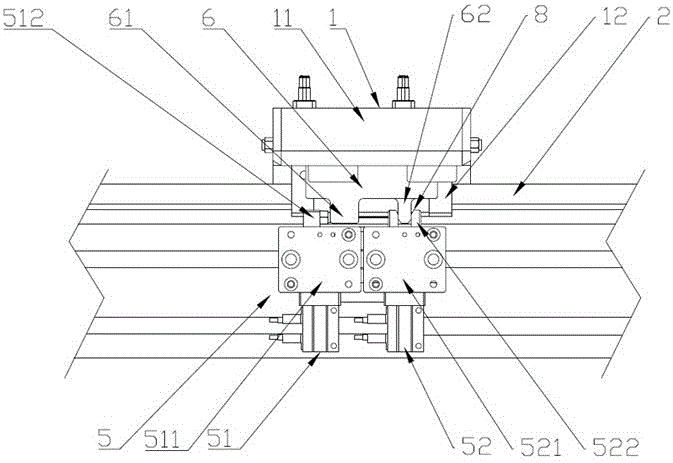

[0026] like figure 1 and figure 2 As shown, a conveying device includes a carrier 1, a guide rail 2 for carrying the carrier 1, a belt 3 for driving the carrier 1, a power mechanism 4 as a power source for the belt 3, and a device for blocking the carrier 1. The positioning mechanism 5 of the position, the guide rail and the belt are ring-shaped, and the best is the shape of a football field runway, so that the conveying device forms an annular circulation conveying structure. The power mechanism 4 is preferably a rotor motor, and the rotor motor is driven and connected with the belt 3; Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com