Continuous discharging mechanism for micro-diameter pipes

A pipe and micro-diameter technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of pipe bending deformation, cut-off end separation, and pipe cutting point cannot be completely pulled away, so as to achieve quantitative accuracy and avoid wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

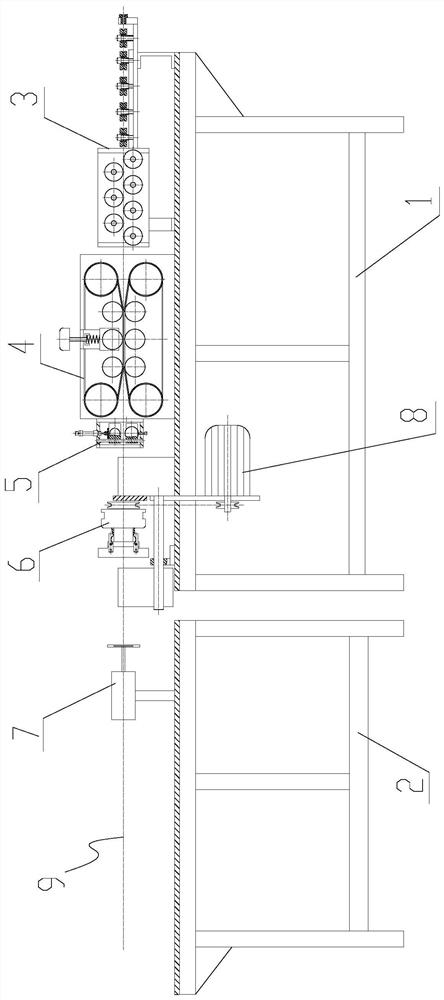

[0028] see figure 1 , the present embodiment is a continuous feeding mechanism for micro-diameter pipes, which consists of the main frame 1 and the blanking frame 2 arranged at the end of the main frame 1 along the central line 9 of the pipeline as the main body of the mechanism.

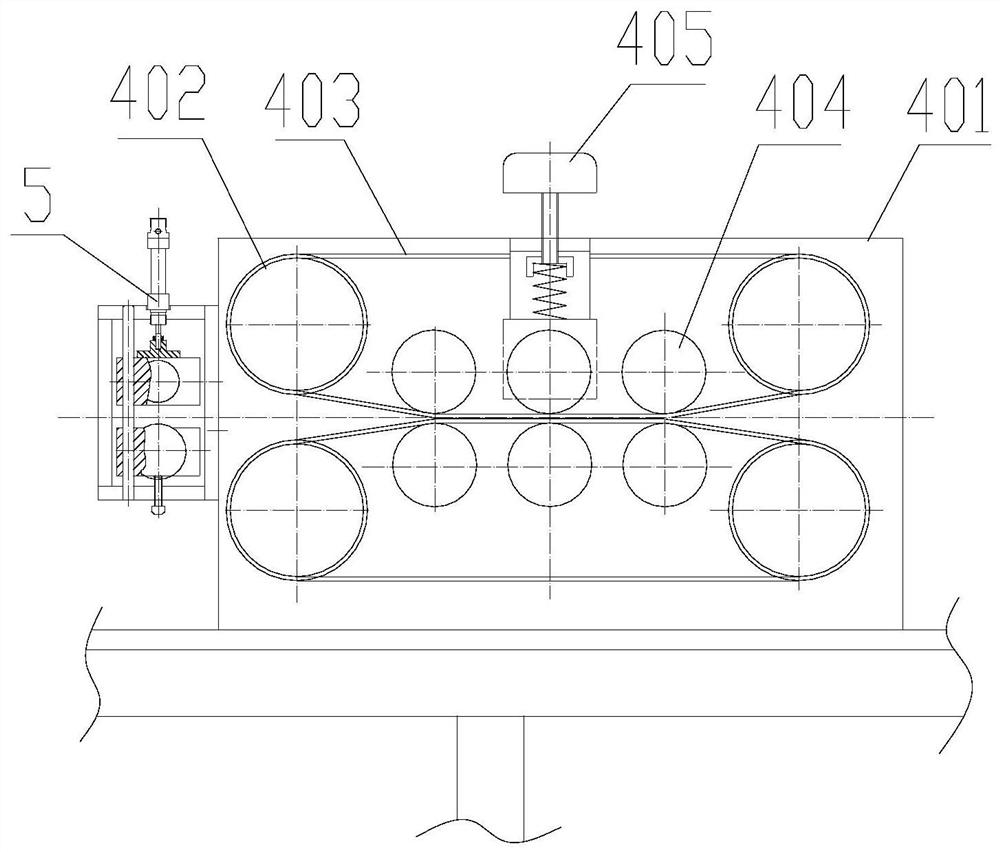

[0029] Wherein the main frame 1 has three parts: a straightening device 3, a belt conveyor 4 behind the straightening device 3, and a cutting device 6 behind the belt conveyor 3. Blanking frame 2 is mainly made up of clapping device 7 and blanking chute etc.

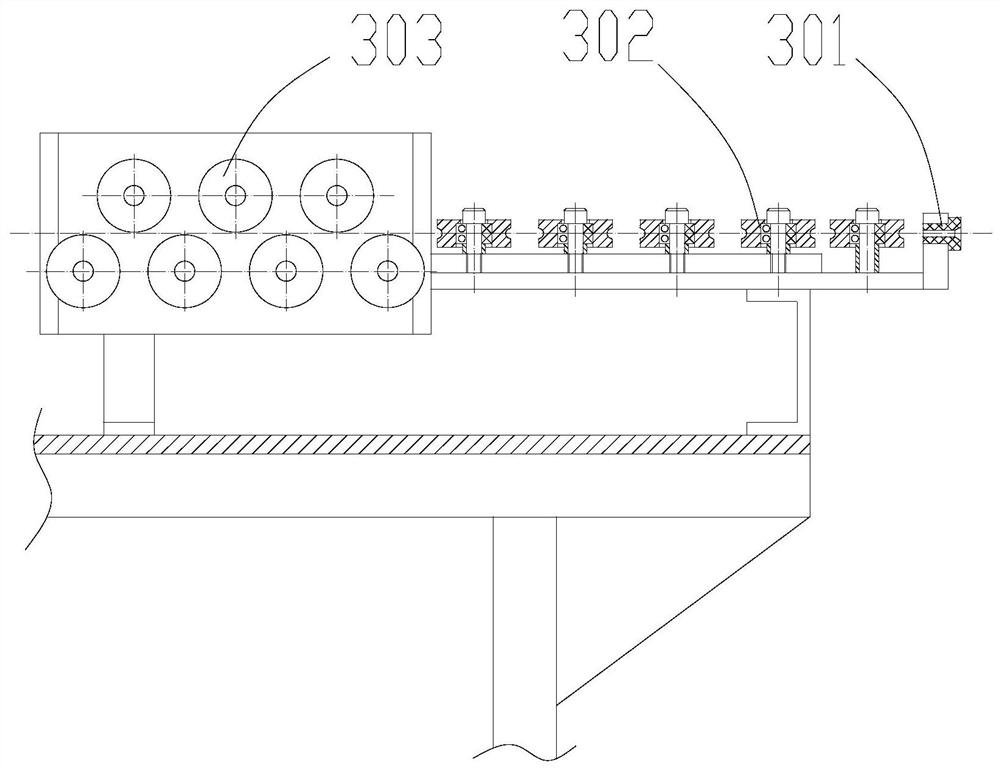

[0030] Straightening device 3 comprises one group of horizontal straightening wheels 302, and horizontal straightening wheels 302 is made up of 5 pairs of single wheels arranged horizontally, notch to notch; Horizontal straightening wheels 302 are followed by vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com